Cement kiln flue gas SDS dry desulfurization and low-dust SCR denitration purification device and process

A dry desulfurization and purification device technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, to achieve the effects of reducing operation and maintenance costs, maximizing activity and service life, and smoothing the inner diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

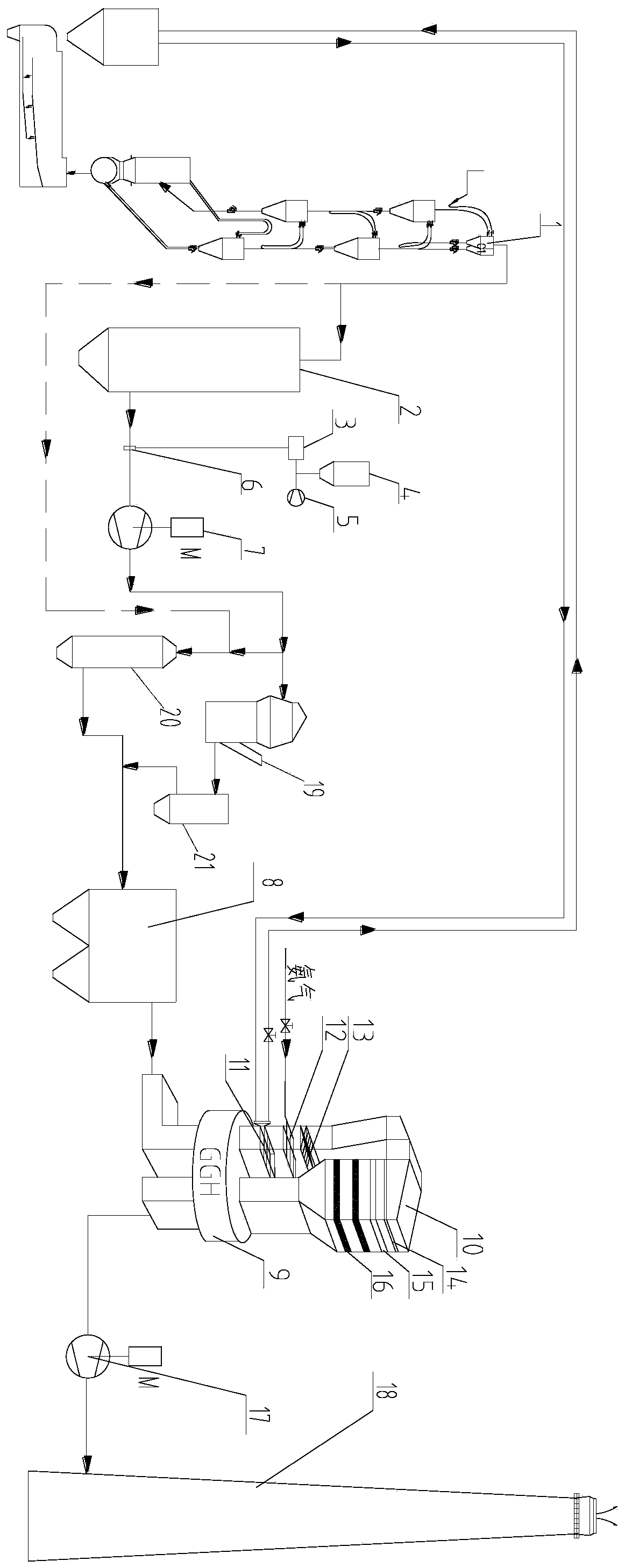

[0023] In order to illustrate the specific implementation steps of the present invention more vividly, the following further description will be made in conjunction with the accompanying drawings.

[0024] Referring to the accompanying drawings, a cement kiln flue gas SDS dry desulfurization and low-dust SCR denitrification purification device includes a desulfurizer mill 3, a desulfurizer powder bin 4, a Roots blower 5, a desulfurizer dosing device 6, and a GGH changer. Heater 9, low-dust SCR denitrification reactor 10, the GGH heat exchanger 9 is a rotary heat exchanger, and the heat exchange elements of the rotary heat exchanger have high heat transfer performance, corrosion resistance, and are not easy to block ash . A desulfurizing agent dosing device 6 is installed between the outlet of the waste heat boiler 2 at the end of the cement kiln and the high-temperature fan 7. The desulfurizing agent dosing device 6 is connected to the desulfurizing agent grinding and conveyin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap