Recoverable biological composite emulsion fracturing fluid and preparation method and utilization method

A composite emulsion and hydraulic technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance, low flowback rate, obvious performance difference, etc., and achieve wide temperature range and good flow Strong performance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

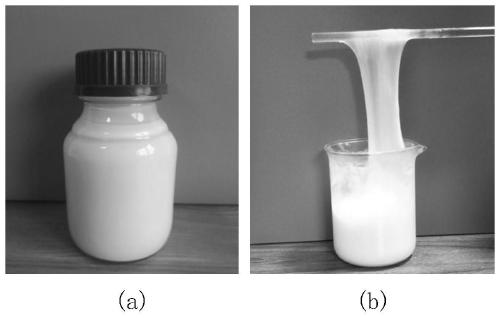

Image

Examples

preparation example Construction

[0028] A method for preparing a recyclable biocomposite emulsion fracturing fluid, comprising the steps of:

[0029] A. Prepare mixed solution: mix acrylate, acrylamide and alkylacrylamide with water to obtain mixed solution;

[0030] B. Preparation of reaction solution: after mixing the mixed solution and methylenebisacrylamide, adding an initiator, and reacting at a constant temperature to obtain a reaction solution;

[0031] C. Preparation of composite emulsion fracturing fluid: add emulsifier, 18% sodium 2-methylpropanesulfonate solution, EDTA, quaternary ammonium salt cationic monomer and fluorine-containing polyfunctional acrylate to the reaction solution , after stirring and reacting, a complex emulsion fracturing fluid is obtained.

[0032] Further, the constant temperature in the step B is 65-70°C, and the reaction time is 1-2h.

[0033] Further, the stirring temperature in step C is 50-55°C; the stirring time is 2-2.5h.

[0034] Further, the method for preparing a...

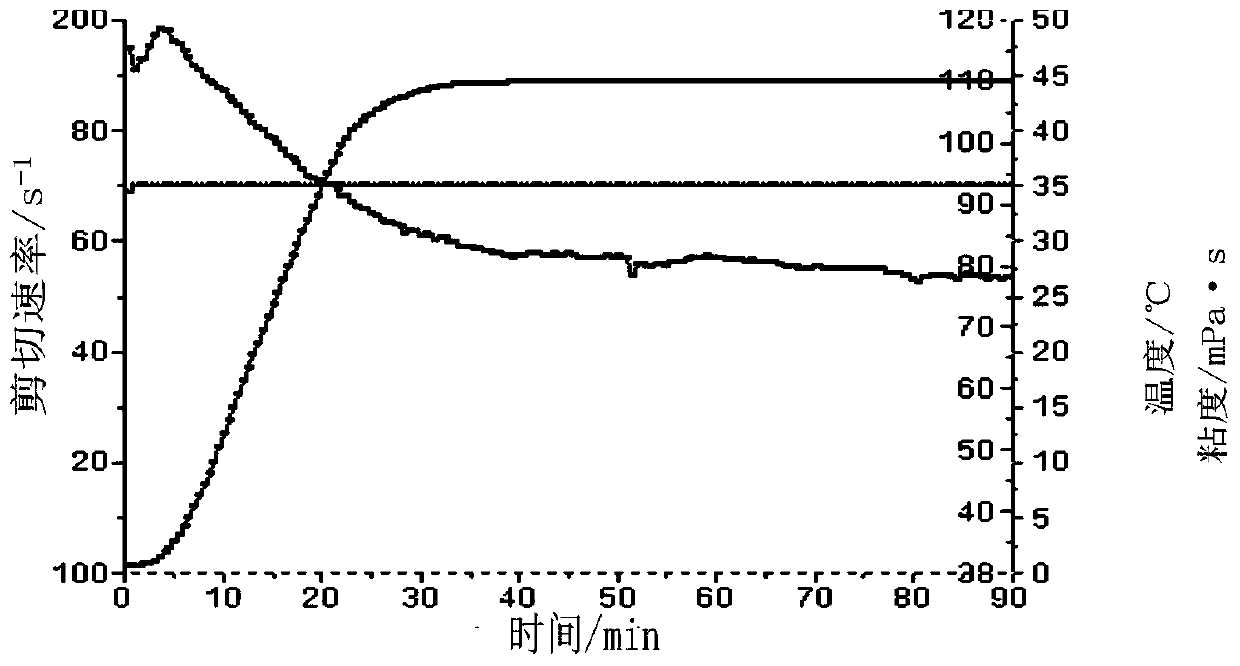

Embodiment 1

[0038]A recyclable biocomposite emulsion fracturing fluid is composed of the following raw materials in weight percentage: acrylate 6%, acrylamide 3%, alkylacrylamide 8%, emulsifier 15%, mass fraction 18% of 2- Sodium methyl propane sulfonate solution 4%, initiator 0.2%, methylenebisacrylamide 5%, EDTA 2%, quaternary ammonium salt cationic monomer 2%, fluorine-containing polyfunctional acrylate 0.2% and the balance of water .

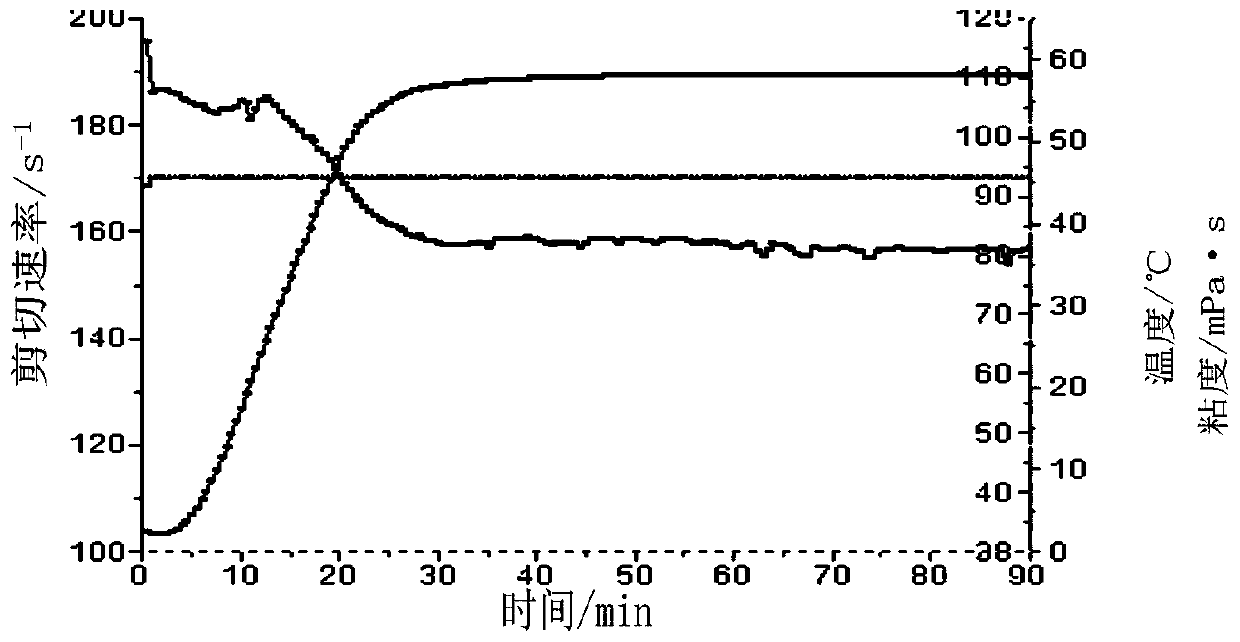

Embodiment 2

[0040] A recyclable biocomposite emulsion fracturing fluid is composed of the following raw materials in weight percent: 12% sodium acrylate, 8% acrylamide, 15% alkylacrylamide, 30% span80 emulsifier, and 18% of 2 -Sodium methyl propane sulfonate solution 8%, potassium persulfate 0.7%, methylenebisacrylamide 10%, EDTA 5%, quaternary ammonium salt cationic monomer 5%, fluorine-containing polyfunctional acrylate 0.8% and the balance of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com