An inverse microemulsion polymer fracturing fluid system that can be applied online

A technology of inverse microemulsion and fracturing fluid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem that the fracturing fluid system cannot complete the construction, and the fracturing fluid forms powder particles or fish eyes. Possibility and other issues are put forward to achieve excellent drag reduction effect, excellent temperature and salt resistance performance, and excellent sand-carrying performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The total salinity of the flowback fluid of a shale gas well is 32000mg / L. The formula components and dosage of the slick water fracturing fluid prepared by using the flowback fluid of the shale gas well are shown in Table 1.

[0037] Table 1, Example 1 slick water fracturing fluid formula components and consumption

[0038]

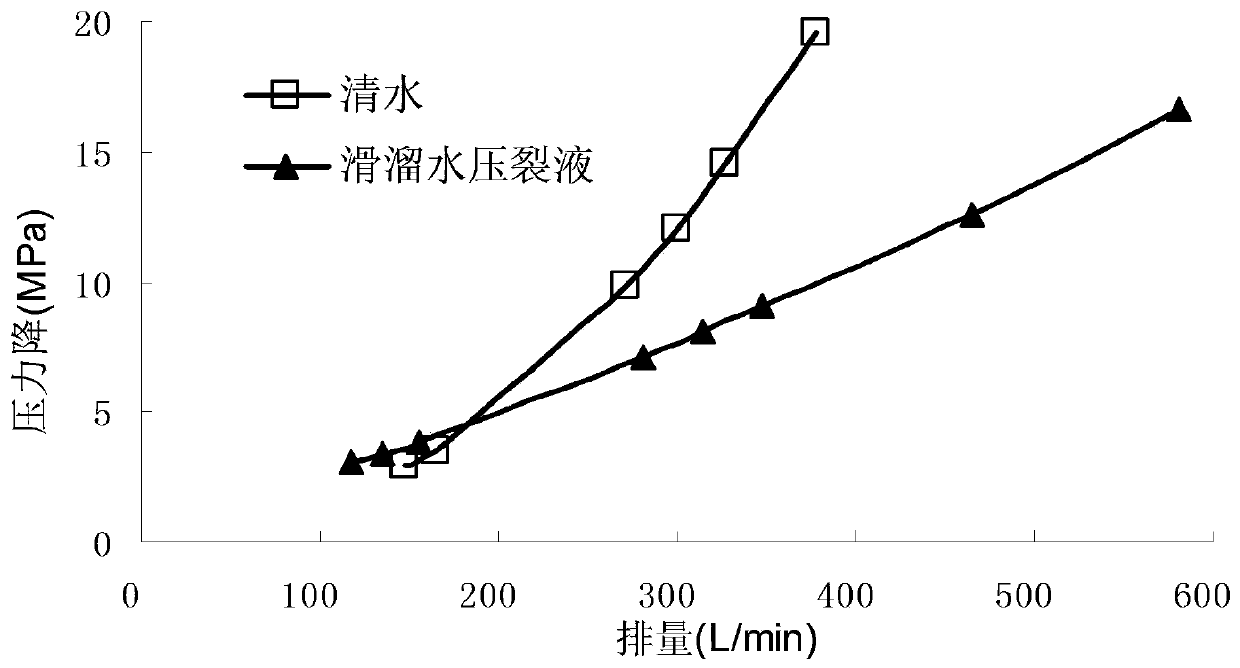

[0039] Test the drag-reducing performance of the above slick water fracturing fluid:

[0040] Test instruments and equipment: Coiled tubing friction test equipment (375m pipeline, inner diameter Φ2.54cm), 700-type fracturing truck, density meter (to measure liquid density).

[0041] Test method: Start the pump of the fracturing vehicle, fill the selected coiled tubing group pipeline and experimental pipeline with clean water, and adjust the clean water displacement in turn (at least 5 displacements are recommended, 0.1, 0.2, 0.3, 0.4, 0.5m 3 / min), each displacement was stabilized for about 1min, and after the test pressure stabilized, the rea...

Embodiment 2

[0046] The formulation components and dosage of a 150°C weak gel fracturing fluid are shown in Table 3.

[0047] Table 3. Components and dosage of the 150°C weak gel fracturing fluid formulation in Example 2

[0048]

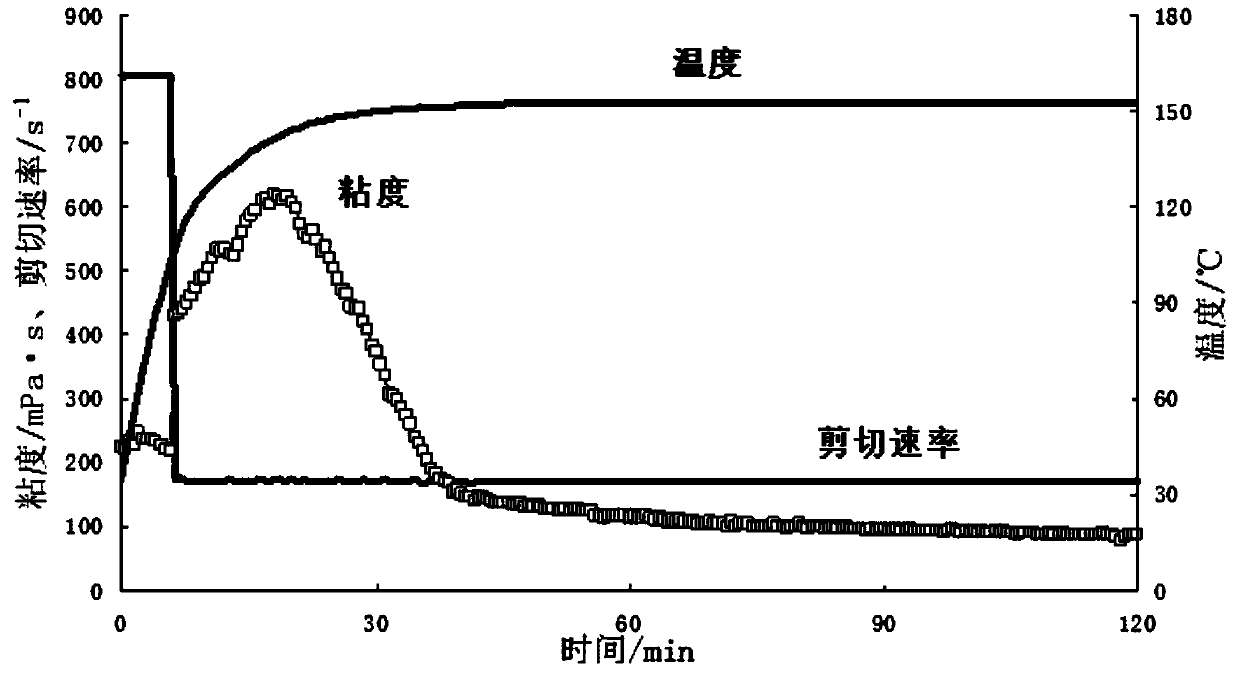

[0049] For a picture display of the weak gel fracturing fluid, see figure 2 . Through a large number of laboratory experiments and simulations, the temperature resistance of the weak gel fracturing fluid system can reach 150 °C. The experimental results of the temperature resistance and shear resistance test of the formula fracturing fluid are shown in image 3 . Fracturing fluid after 800s -1 The liquid viscosity is low at high speed shear, but the shear rate drops to 170s -1 Afterwards, the viscosity increased rapidly again, and after 120 minutes, the viscosity of the fracturing fluid remained above 50mPa·s, indicating that it has excellent temperature and shear resistance.

Embodiment 3

[0051] The present invention provides an optimization scheme for the 120°C weak gel fracturing fluid formula for on-line construction, as shown in Table 4. Among them, the total salinity of water source in Yanchang well is 25000mg / L.

[0052] Table 4. 120°C Weak Gel Fracturing Fluid Formulation Components and Dosage for Online Construction in Example 3

[0053]

[0054] Indoor simulated on-line construction process: add dosing water to the mixer, add instant emulsion thickener, clay stabilizer, functional additive, and weak crosslinking agent according to the above ratio under stirring conditions, and measure it immediately after mixing evenly 70ml of fracturing fluid was transferred to the RS6000 rheometer rotating cylinder test system for temperature resistance and shear resistance test, the results are shown in Figure 4 . It can be seen from the viscosity-time curve that when using high-salinity water source to prepare fracturing fluid and carry out on-line constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com