Deslagging method in vertical shaft excavation process

A technology for shaft and well washing, which is applied to shaft equipment, earth-moving drilling and wellbore flushing, etc., can solve the problems of inability to discharge slag, insufficient drilling gas hydraulic pressure, etc., and achieve the effect of large particle size particle slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

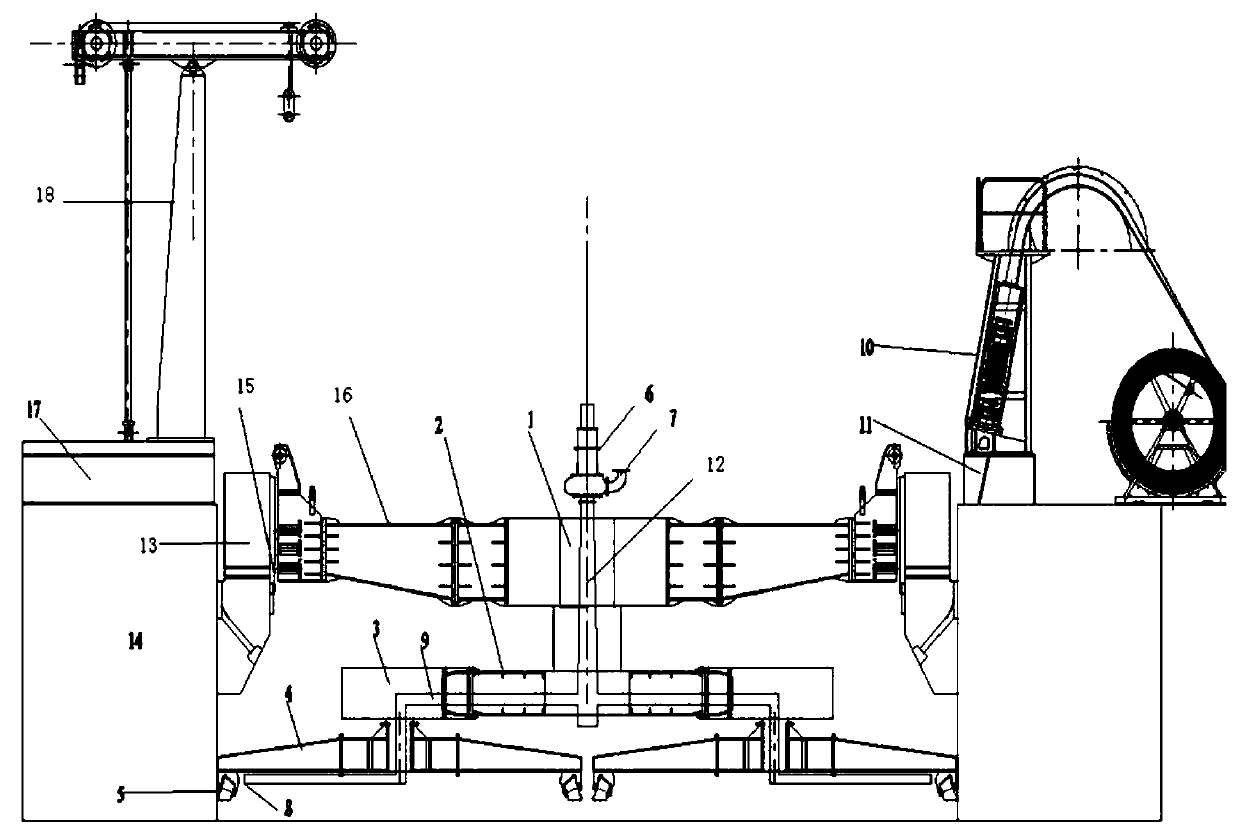

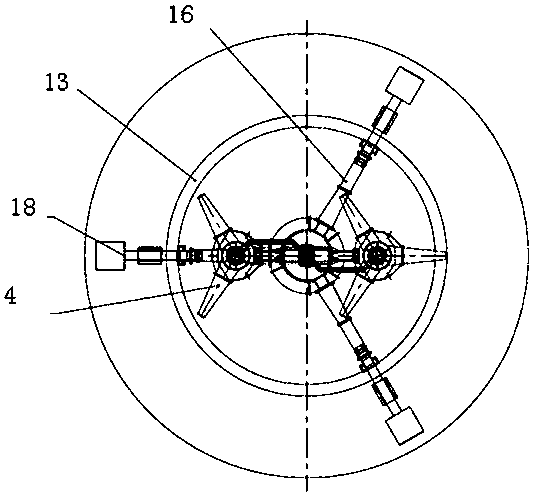

[0018] Such as figure 1 , 2 As shown, a method for removing slag during the excavation of a vertical shaft adopts a multi-absorbing port pump suction lift mixed type well washing and slag removal system; the steps are as follows:

[0019] 1). Install the slag discharge device, install the mud pump on the three-arm tunneling frame of the roadheader; install multiple suction ports evenly through the pipeline to the bottom of the cutter head of the roadheader;

[0020] 2). The pump-suction-lifting mixed-type well washing and slag discharge. During the excavation process, the well is always full of mud and slag. The sinking shaft roadheader drives the cutter head to rotate, and the cutter head begins to dig downward under the action of gravity. The sludge produced by excavation and the water injected into the well form a mud liquid under the agitation of the self-rotating cutterhead of the shaft boring machine;

[0021] a. Pump suction method, under the action of the mud pump 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com