Rotary kiln denitration and dust removal integrated device

A technology of denitration and dust removal and rotary kiln, which is applied in the integrated field of denitration and dust removal of rotary kiln, can solve the problems of secondary pollution, complexity, and no denitration and dust reduction, and achieves the effect of sufficient oxygen and reduced errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

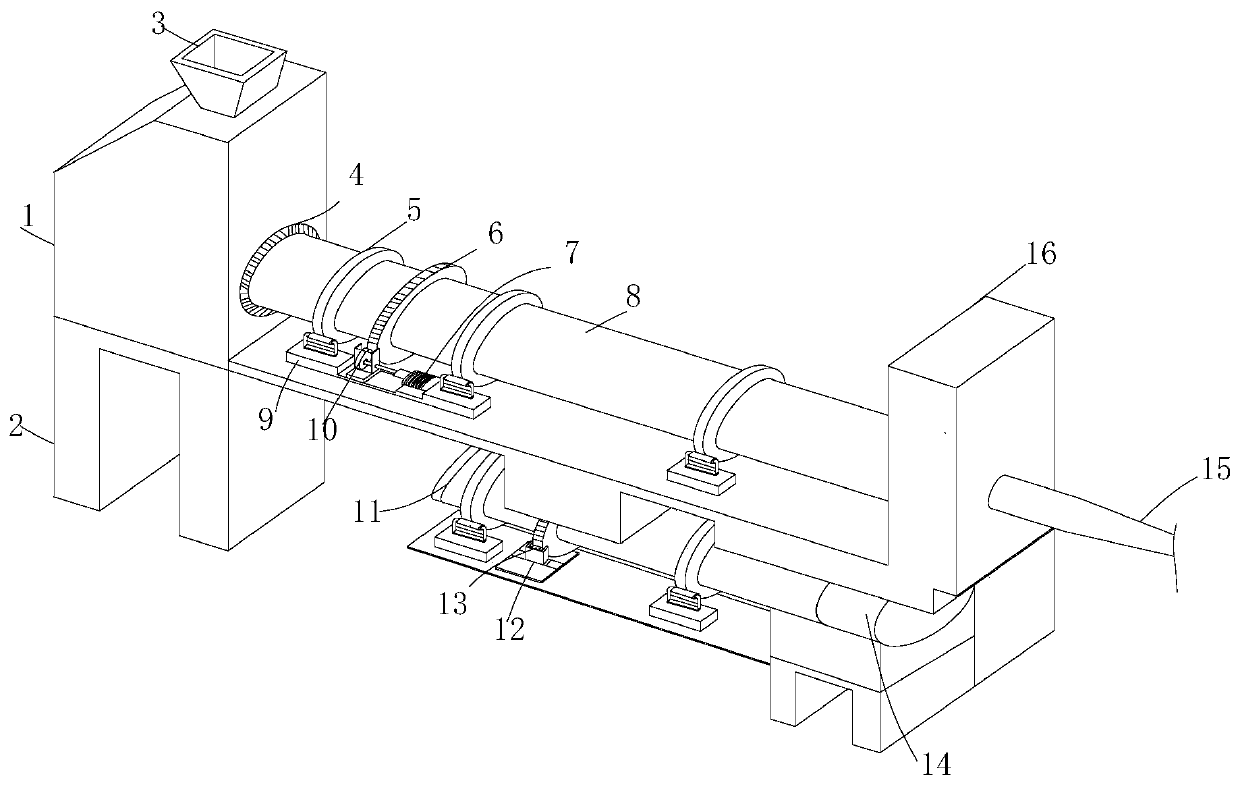

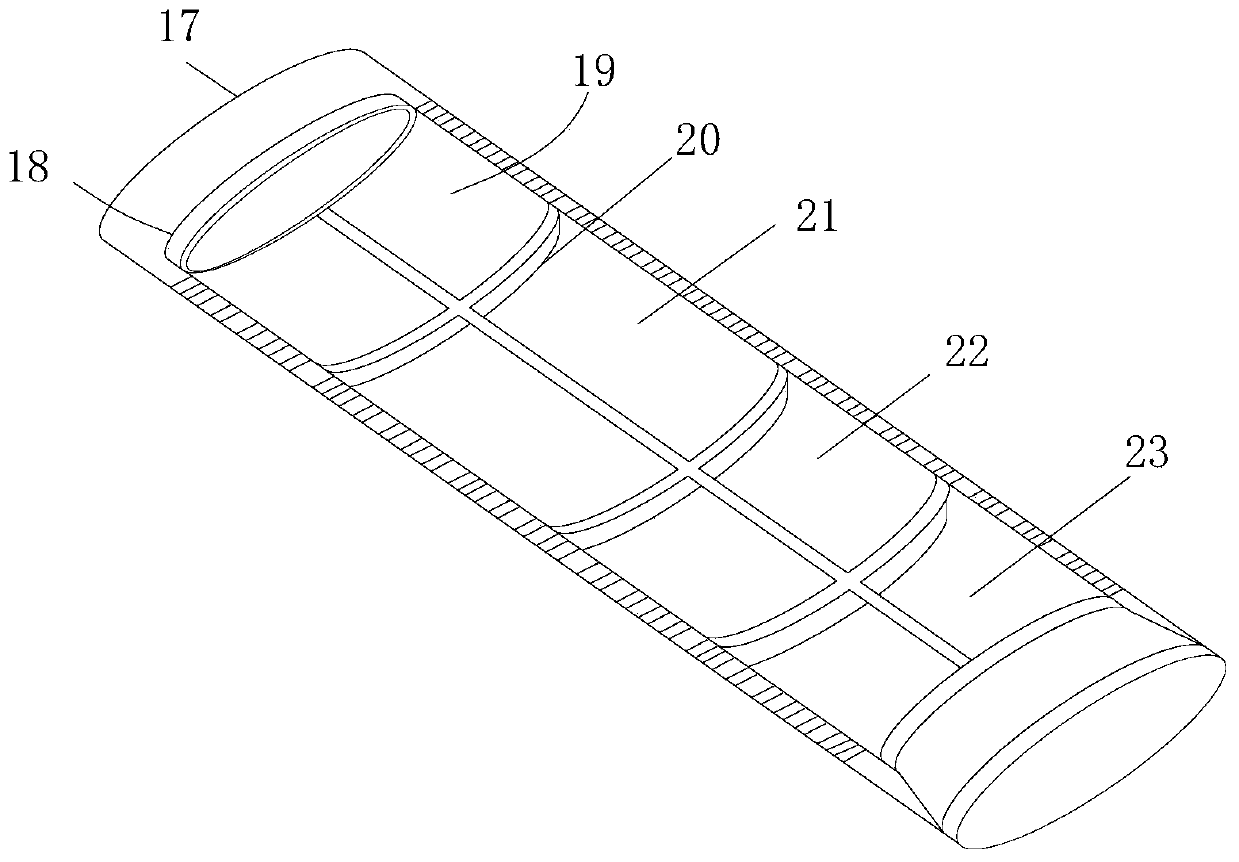

[0032] Such as Figure 1 to Figure 6 As shown, the rotary kiln denitrification and dust removal integrated device according to the preferred embodiment of the present invention includes a kiln tail smoke chamber 1, a rotary drum 8 and a coal injection pipe 15, and a feed inlet 3 is installed on the top of the kiln tail smoke chamber 1, and the feed A feeding pipe 38 is installed at the outlet of port 3, the right side of the kiln tail smoke chamber 1 is fixedly connected with the rotary drum 8, and a kiln kiln is installed at the contact part of the feed end of the rotary drum 8 and the right side of the kiln tail smoke chamber 1. Tail seal 4, wheel belt 5 and large toothed disc 6 are respectively installed on the outer wall of rotary cylinder 8, supporting tray 9 is arranged below wheel belt 5, small toothed plate 10 is arranged below large toothed plate 6, and the rotating cylinder 8 A motor 7 is arranged below, and the output shaft of the motor 7 is fixedly connected with t...

Embodiment 2

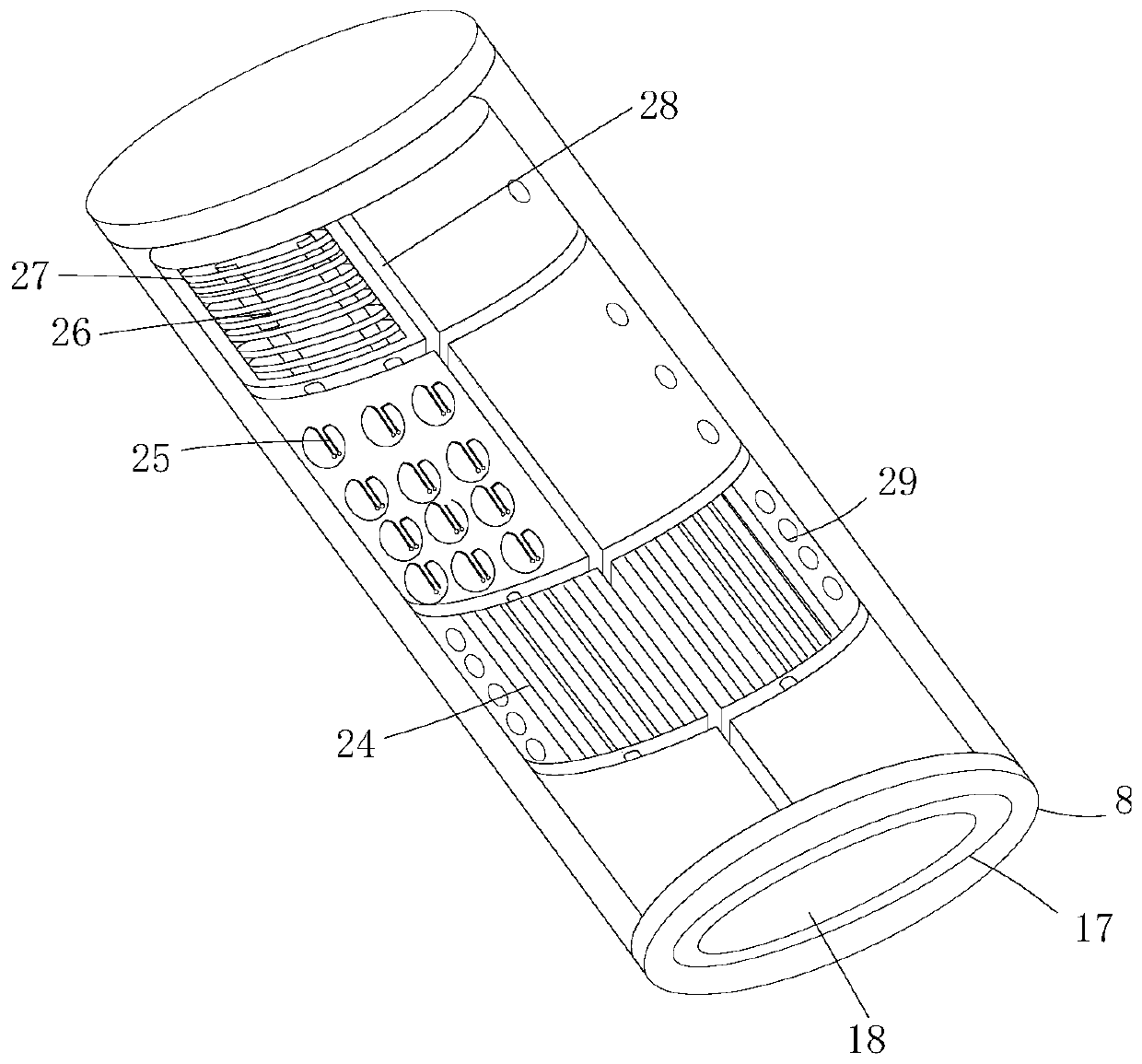

[0034] In a preferred embodiment, a heating conduit 26 is installed on the inner wall of the annular outer ring tube 27 to make it heat the air, and the left and right sides of the inner wall of the high-power heater 24 are provided with air guide holes 29. Connect one group of air ducts on the outer wall of 8 and be connected with air guide hole 29.

[0035] In a preferred manner, the output port of the coal injection pipe 15 is connected with an air-air mixing conduit 37, and a vortex conduit 30 is installed above the outer wall of the air-air mixing conduit 37, and the air inlet of the vortex conduit 30 is connected with a combustion-supporting air conduit 31, and the combustion-supporting air conduit The right wall of 31 is connected with central air duct 33, and the middle part of central air duct 33 is equipped with valve 32, and the bottom of air-gas mixing duct 37 is equipped with central air duct 35, and the inner chamber wall of central air duct 35 is equipped with in...

Embodiment 3

[0037] In a preferred embodiment, the tire belt 5 is slidingly connected to the wall surface of the support tray 9, and the support trays 9 are respectively a combination of a pinion and a tray, and the pinion gear contacts the outer wall of the tire belt 5 so as to limit the rotation cylinder 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com