Flue gas heat exchanger beneficial to cleaning

A flue gas heat exchanger and flue gas technology, which is applied in the direction of cleaning heat transfer devices, heat exchange equipment, non-rotating equipment cleaning, etc., can solve the problems of reducing the working efficiency of the flue gas heat exchanger and shutting down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

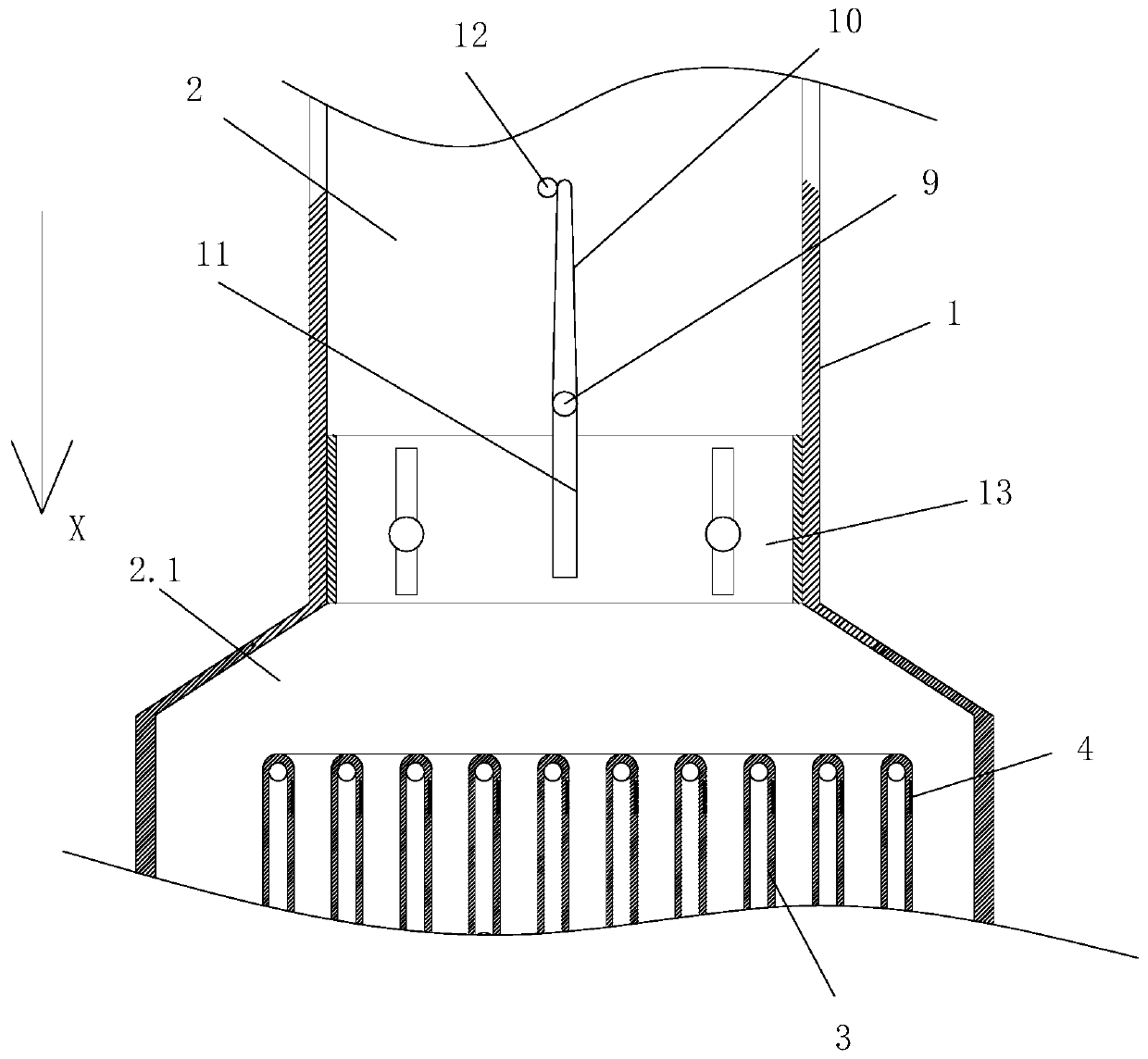

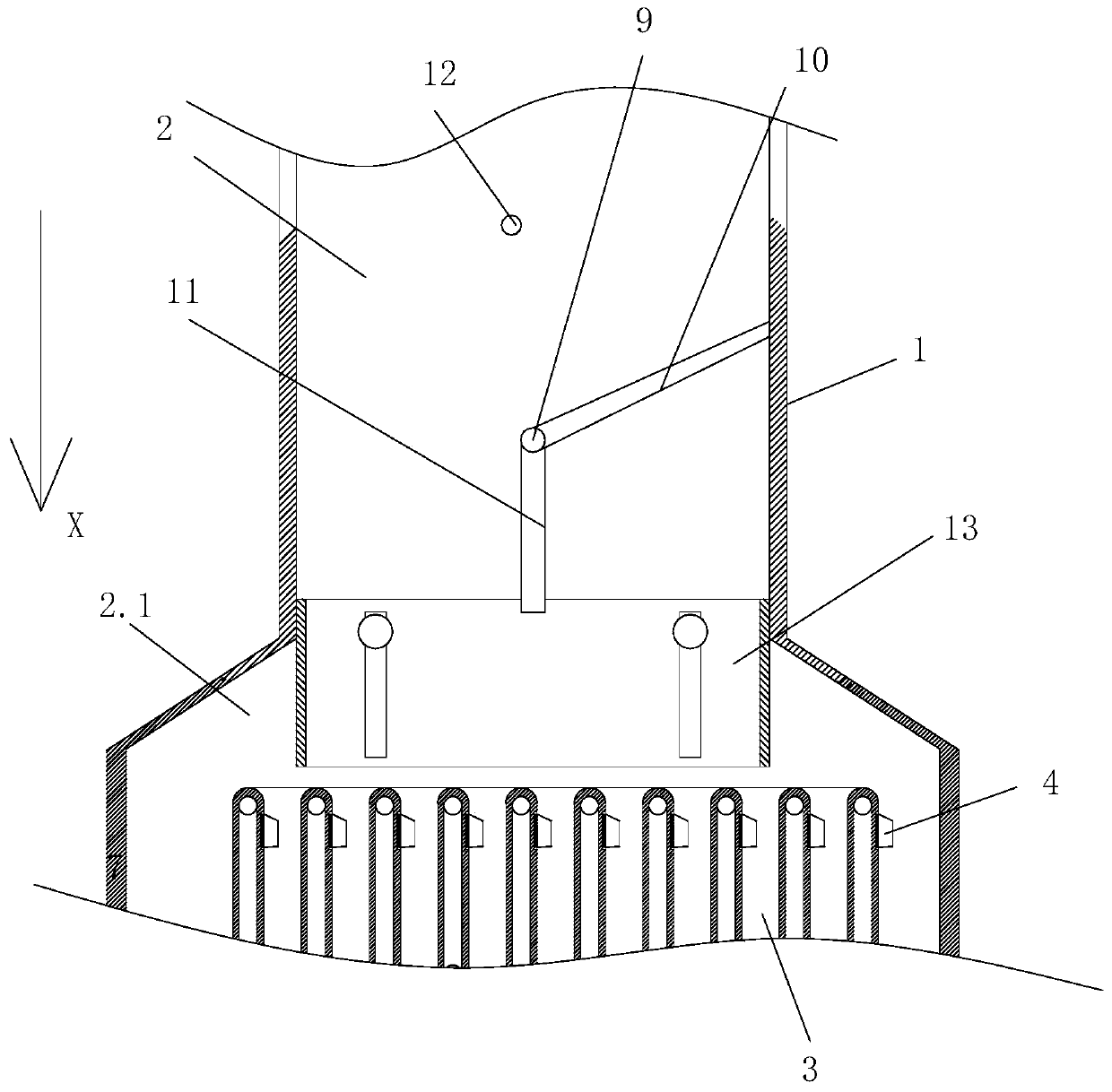

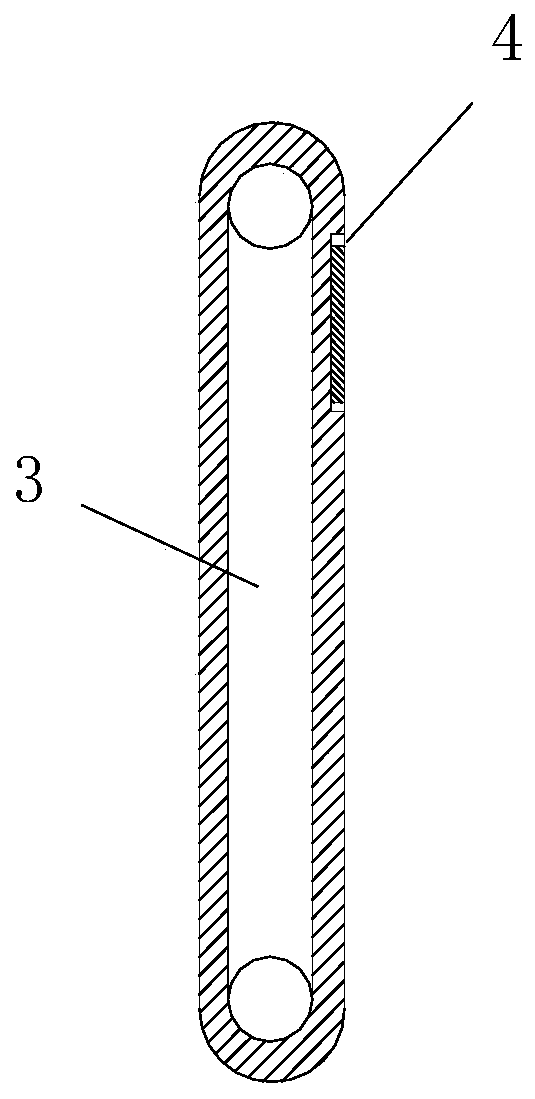

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] The present invention involves a large number of descriptions of turbulent flow and laminar flow, where both turbulent flow and laminar flow are fluid flow states. The fluid flows in layers and does not mix with each other, which is called laminar flow, also known as steady flow or sheet flow; when the streamlines are no longer clearly discernible, there are many small eddies in the flow field, and the laminar flow is destroyed. There is not only sliding, but also mixing. At this time, the fluid moves irregularly and has a component velocity perpendicular to the axis of the flow tube. This movement is called turbulent flow, also known as turbulent flow, turbulent flow, disturbed flow or turbulent flow. Laminar and turbulent flow can be di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com