A system for on-line testing of high-temperature corrosion of water-cooled walls

A high-temperature corrosion and online testing technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of low accuracy of high temperature corrosion degree monitoring, poor reliability and system stability, etc., and achieve reduction and popularization cost, improve reliability and stability, and reduce layout effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

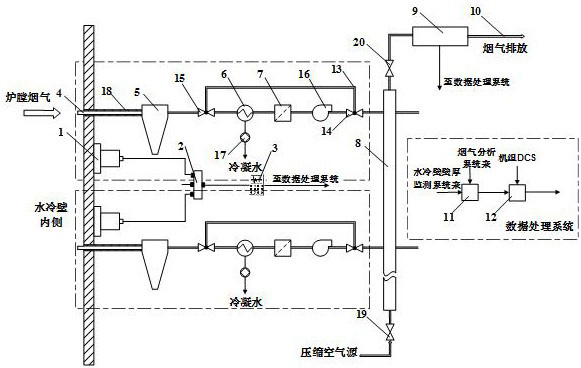

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

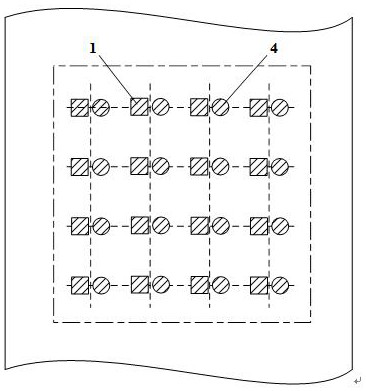

[0027] refer to Figure 1-2 , a system for realizing online testing of high-temperature corrosion of water-cooled walls, including a water-cooled wall thickness monitoring system, a flue gas sampling and pretreatment system, a flue gas analysis system, and a data processing system; the water-cooled wall thickness monitoring system includes: setting The ultrasonic high-temperature probe device 1 on the outside of the water-cooled wall, the inner side of the water-cooled wall is a furnace through which high-temperature flue gas passes, and the ultrasonic high-temperature probe device 1 is connected with a signal transmission and channel switching device 2 and a digital signal excitation receiving device 3 in sequence. The signal transmission and channel switching device 2 can transmit electrical signals between the ultrasonic high-temperature pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com