Electric soldering iron heating type rapid thermal fatigue test device and test method

An experimental device and heating technology, which is applied in the field of electric soldering iron heating type rapid thermal fatigue experimental device, can solve the problems of lower temperature in the low temperature section, high experimental cost, and high cost, and achieve fast heating rate, shortened experimental time, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

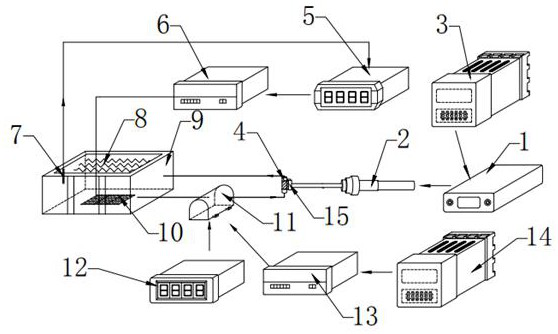

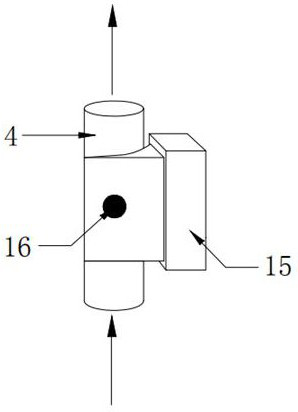

[0024] This embodiment provides an electric soldering iron heating type rapid thermal fatigue experimental device and experimental method, such as figure 1 , figure 2As shown, the electric soldering iron heating type rapid thermal fatigue experiment device includes a heating system, a refrigeration system, a cooling liquid circulation system and a counting system, and the heating system includes a heating power supply 1 and a welding handle 2 electrically connected to the heating power supply 1. 2 is provided with a welding nozzle 15 at the end of the welding nozzle 15, a sample placement point 16 is provided at the side end of the welding nozzle 15, and a first cycle time relay 3 electrically connected to the heating power source 1 is also provided. 3 The heating time and pause time of the heating power supply 1 can be set, and a first switching power supply 6 connected to the cooling plate 10 is also provided between the temperature controller 5 and the water tank 9; 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com