Carbon black dispersion body, photosensitive resin composition, color filter and display device

A technology of dispersion and carbon black, which is applied in the fields of carbon black dispersion, color filter, photosensitive resin composition and display device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] According to another aspect of the present invention, the preparation method of carbon black dispersion as described above is provided, comprising the following steps:

[0069] According to another aspect of the present invention, the preparation method of carbon black dispersion as described above is provided, comprising the following steps:

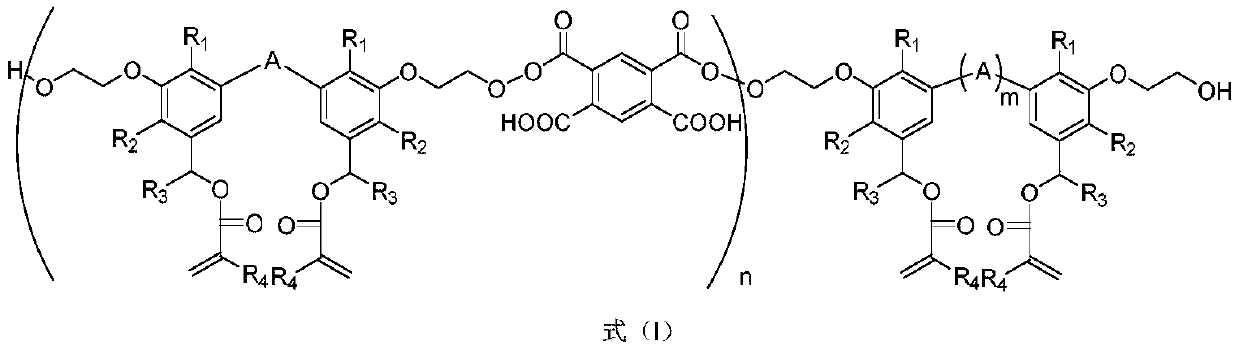

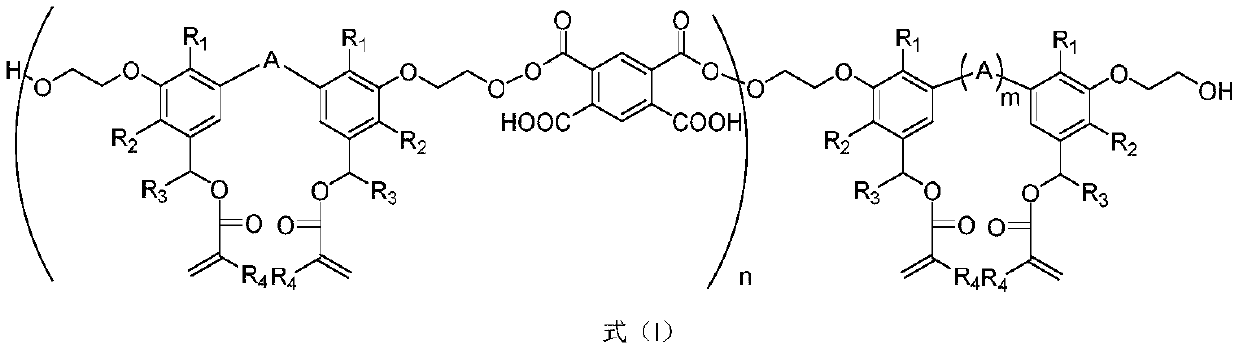

[0070] The carbon black dispersion is obtained by dispersing the solvent, the (meth)acrylate adduct represented by the formula (I), the dispersant, and the carbon black subjected to surface oxidation treatment.

[0071] According to one embodiment of the present invention, the preparation method of carbon black dispersion can comprise the following steps:

[0072] Stir the solvent, the (meth)acrylate adduct represented by the formula (I) and the dispersant evenly, then add the carbon black treated with surface oxidation and disperse to obtain the carbon black dispersion.

[0073] Specifically, in the preparation process, the sti...

preparation Embodiment 2

[0087] Preparation Example 2 Preparation of methacrylate adduct I-1

[0088] Add 4mol of monomer 1, 1mol of monomer 2, catalyst Pd into a 500mL round bottom flask 2 dba 3 · CHCl 3 / Xantphos, CS 2 CO 3 and the solvent dioxane, heated to 100°C, and reacted for 2 hours to obtain compound A. 1 mol of compound A, 1 mol of pyromellitic dianhydride and propylene glycol methyl ether acetate (PMA) were placed in a round bottom flask, and reacted at 80°C for 2 hours to obtain the methacrylate adduct I-1. Mw=5103, acid value 101.7.

[0089]

preparation Embodiment 3

[0090] Preparation Example 3 Preparation of methacrylate adduct I-2

[0091] The preparation method is basically the same as that of Preparation Example 2, except that the monomer 1 is different, and the monomer 2 is not used. Mw=5017, acid value 100.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com