Complex-phase multiferroic material with non-volatile magnetothermal effect regulated and controlled by electric field as well as preparation method and application of complex-phase multiferroic material

A magneto-caloric effect and electric field control technology, applied in the manufacture/processing of electromagnetic devices, material selection, etc., can solve the problems of high equipment requirements, volatile magneto-caloric effect, unfavorable practical application, etc., and achieve the expansion of refrigeration working temperature range , wide effective cooling temperature zone and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

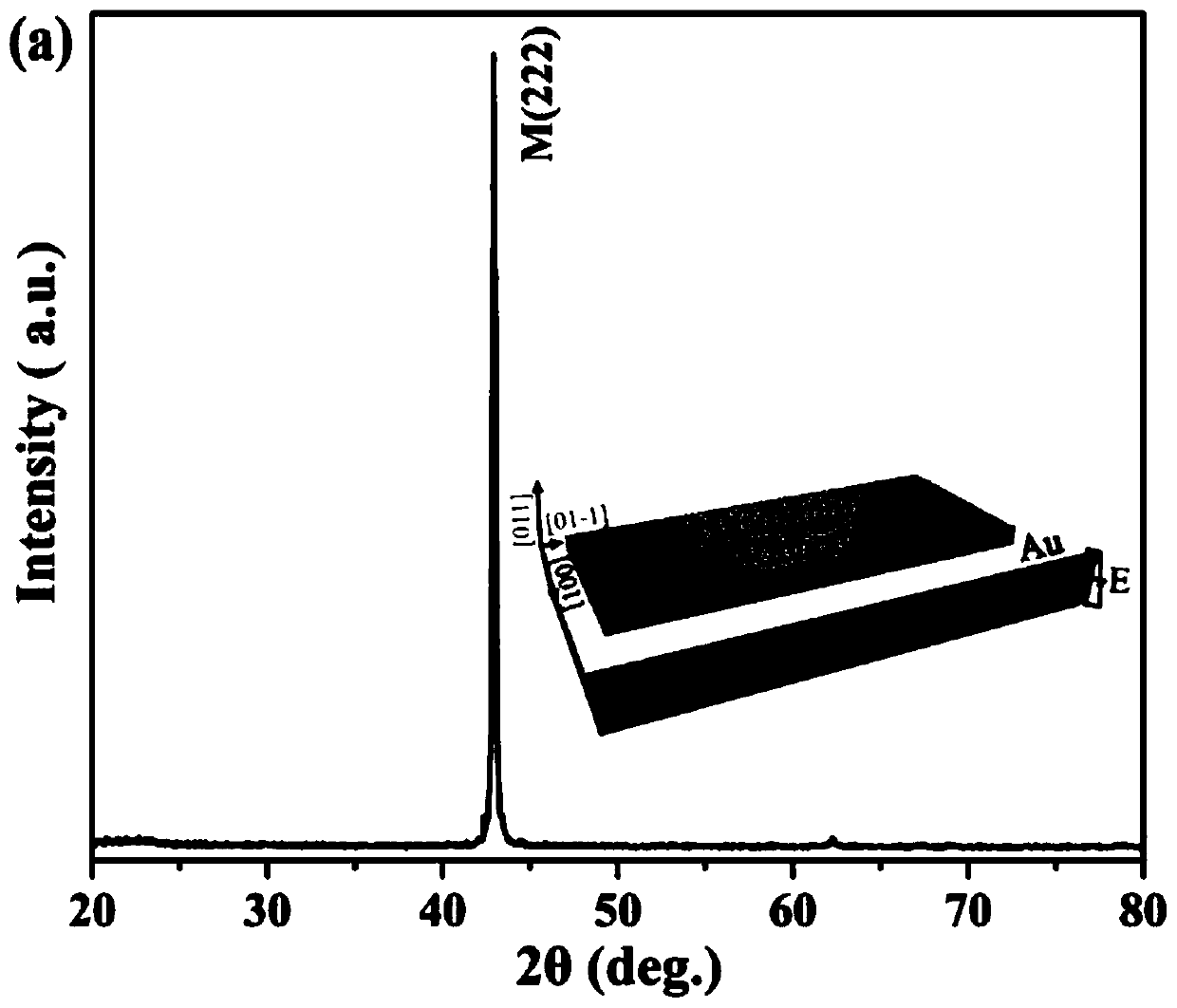

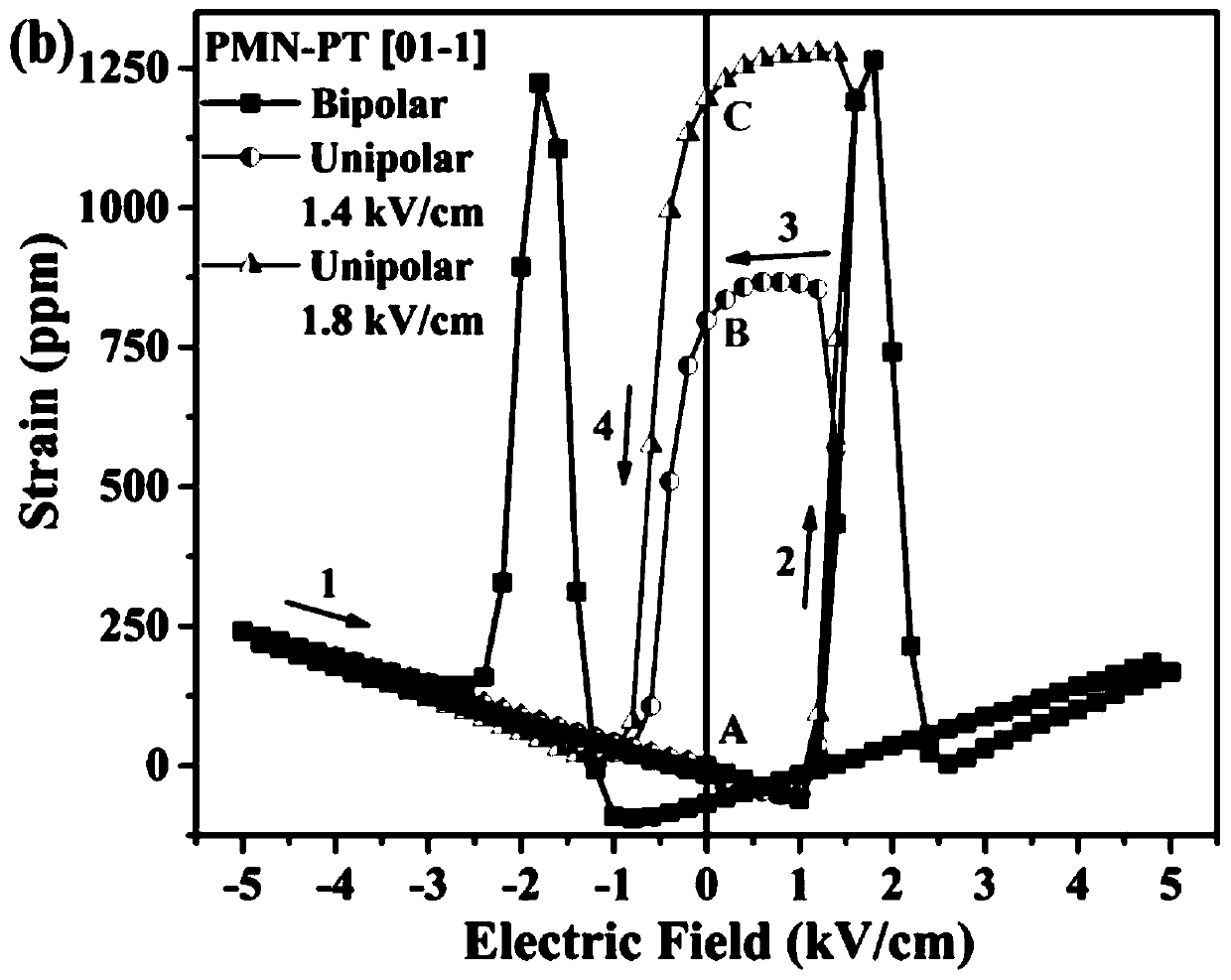

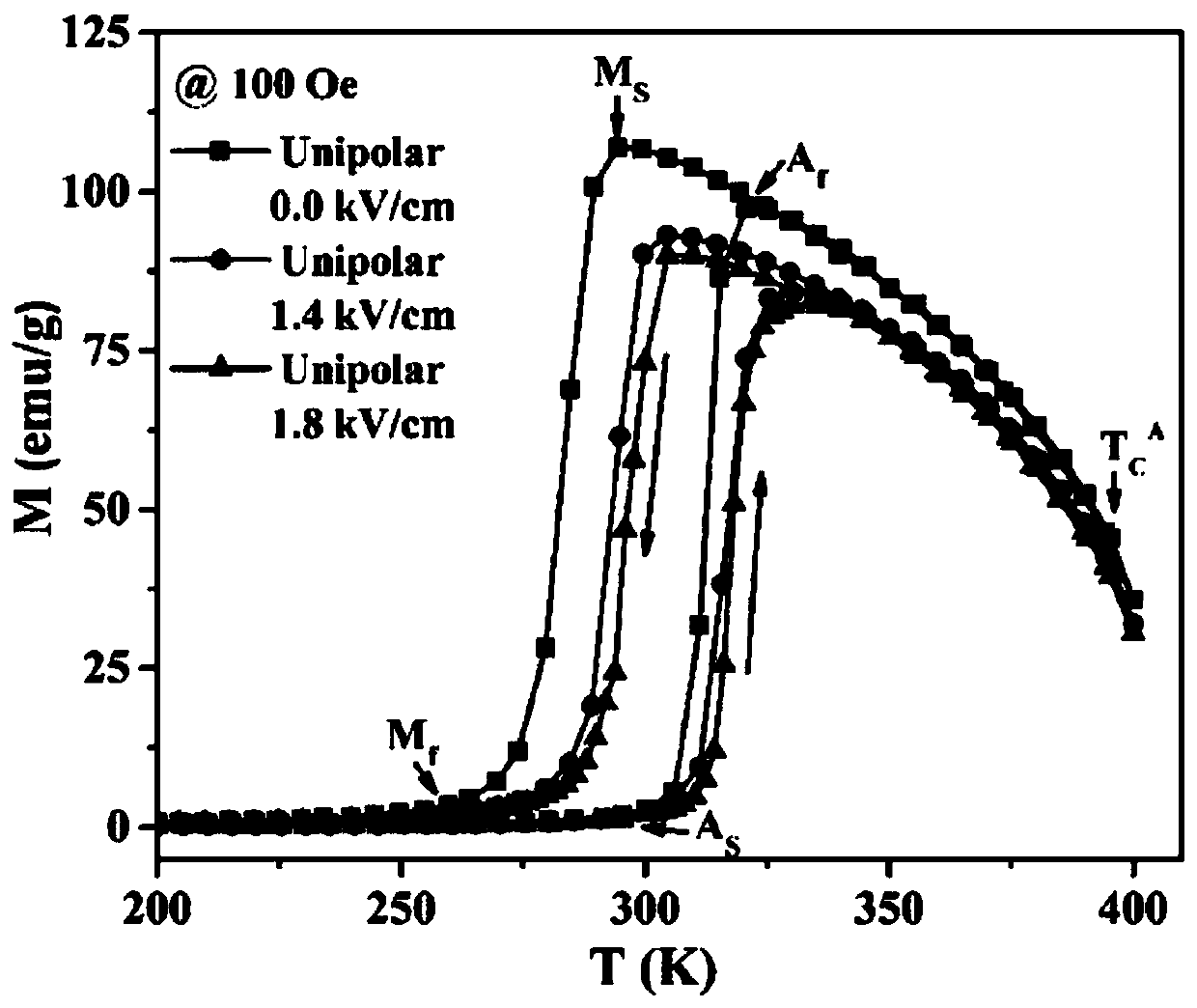

[0042] A kind of multiphase multiferroic material with non-volatile electric field regulation magnetocaloric effect, described multiphase multiferroic material is pasted by a Ni-Co-Mn-Sn alloy thin strip on the upper and lower surfaces coated with a layer of gold film PMN-PT single crystal substrate composition, its preparation method comprises the following steps:

[0043] 1) Preparation of thin metal strips: high-purity Ni, Mn, Co, Sn metal raw materials are prepared into Ni 43 co 7 mn 39 sn 11 The Ni-Co-Mn-Sn alloy thin strip; wherein the rotation speed of the molybdenum wheel in the preparation process of the alloy thin strip is 10 m / s, and the length of the thin strip thrown out is 2 cm, and the thickness is 20 μm; the rapid quenching The steps are as follows: seal the prepared Ni-Co-Mn-Sn alloy thin strip in a vacuum quartz tube, anneal at 800°C for 5 minutes, and then rapidly quench in ice water.

[0044] (2) Substrate surface coating: a layer of gold film with a th...

Embodiment 2

[0048] A kind of multiphase multiferroic material with non-volatile electric field regulation magnetocaloric effect, described multiphase multiferroic material is pasted by a Ni-Co-Mn-Sn alloy thin strip on the upper and lower surfaces coated with a layer of gold film PMN-PT single crystal substrate composition, its preparation method comprises the following steps:

[0049] Preparation of thin metal strips: high-purity Ni, Mn, Co, Sn metal raw materials are prepared into Ni 43 co 7 mn 39 sn 11 The Ni-Co-Mn-Sn alloy strip; wherein the rotation speed of the molybdenum wheel in the preparation process of the alloy strip is 30 m / s, and the length of the thin strip thrown out is 3 cm, and the thickness is 30 μm; the rapid quenching The steps are as follows: seal the prepared Ni-Co-Mn-Sn alloy thin strip in a vacuum quartz tube, anneal at 950°C for 15 minutes, and then rapidly quench in ice water.

[0050] (2) Substrate surface coating: A gold film with a thickness of 180 nm was...

Embodiment 3

[0054] A kind of multiphase multiferroic material with non-volatile electric field regulation magnetocaloric effect, described multiphase multiferroic material is pasted by a Ni-Co-Mn-Sn alloy thin strip on the upper and lower surfaces coated with a layer of gold film PMN-PT single crystal substrate composition, its preparation method comprises the following steps:

[0055] (1) Preparation of thin metal strips: high-purity Ni, Mn, Co, Sn metal raw materials are prepared by arc melting and melt rapid quenching into Ni 43 co 7 mn 39 sn 11 Ni-Co-Mn-Sn alloy thin strip; Wherein the rotating speed of molybdenum wheel is 20 m / s in the preparation process of alloy thin strip, the thin strip length that throws out is 3 cm, and thickness is 20 μm; Described quick quenching step The method is as follows: the prepared Ni-Co-Mn-Sn alloy thin strip is sealed in a vacuum quartz tube, annealed at 850° C. for 10 minutes, and then rapidly quenched in ice water.

[0056] (2) Coating on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com