Lithium battery core slurry preparation method

A lithium battery and cell technology, applied in the field of lithium battery cell slurry preparation, can solve the problems of high cost and high battery cost, and achieve the effects of increasing energy density, improving stirring efficiency, and speeding up the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

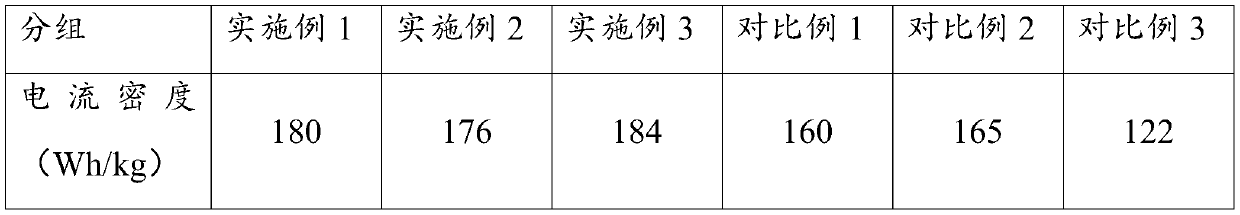

Examples

Embodiment 1

[0026] A preparation method of lithium battery cell slurry provided in this embodiment includes the preparation of positive electrode slurry and negative electrode slurry:

[0027] The preparation process of the positive electrode slurry comprises the following steps:

[0028] The positive electrode slurry comprises the following raw material components by mass ratio: lithium hydroxide 65%, manganese dioxide 25%, polyvinylidene fluoride 2%, conductive graphite 3%, silicone oil 0.5% and N-methylpyrrolidone;

[0029] S1. Mix and grind lithium hydroxide and manganese oxide according to the mass ratio of 1:5. The manganese oxide is manganese dioxide, and then place it in a resistance furnace for calcination at 460°C for 8 hours, then raise the temperature to 720°C for 5 hours, and then calcine at 550°C Insulate for 8 hours to obtain a calcined product, and then grind the calcined product into powder for later use;

[0030] S2. Dry the positive electrode conductive agent in an ove...

Embodiment 2

[0036] A preparation method of lithium battery cell slurry provided in this embodiment includes the preparation of positive electrode slurry and negative electrode slurry:

[0037] The preparation process of the positive electrode slurry comprises the following steps:

[0038] The positive electrode slurry contains the following raw material components in mass ratio: lithium hydroxide 70%, manganese dioxide 28%, polyvinylidene fluoride 2%, conductive graphite 3%, silicone oil 0.6% and N-methylpyrrolidone,

[0039] S1. Mix and grind lithium hydroxide and manganese oxide according to the mass ratio of 2:5. The manganese oxide is manganese dioxide, and then place it in a resistance furnace for calcination at 450°C for 6h, then heat up to 700°C for 4-6h, 580 Insulate at ℃ for 8 hours to obtain a calcined product, and then grind the calcined product into powder for later use;

[0040] S2. Dry the positive electrode conductive agent in an oven at 110° C. for 1.5 hours;

[0041] S3...

Embodiment 3

[0046] A preparation method of lithium battery cell slurry provided in this embodiment includes the preparation of positive electrode slurry and negative electrode slurry:

[0047] The preparation process of the positive electrode slurry comprises the following steps:

[0048] The positive electrode slurry contains the following raw material components in mass ratio: lithium hydroxide 64%, manganese dioxide 26%, polyvinylidene fluoride 2%, conductive graphite 3%, silicone oil 0.4% and N-methylpyrrolidone,

[0049] S1. Lithium hydroxide and manganese oxide are mixed and ground according to the mass ratio of 1:4, and then placed in a resistance furnace for calcination at 480°C for 6h, then heated to 750°C for 4h, and kept at 580°C for 8h to obtain a calcined product, and then Grinding the calcined product into powder for subsequent use;

[0050] S2. Dry the positive electrode conductive agent in an oven at 100° C. for 2 hours;

[0051] S3. Add polyvinylidene fluoride and N-met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com