Lithium ion battery and positive electrode plate thereof and preparation method thereof

A technology for lithium-ion batteries and positive plates, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low potential chemical reaction activity, affecting battery performance, and electrolyte system damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] This embodiment provides a positive electrode sheet suitable for a lithium ion battery, which mainly includes a current collector, a positive electrode active material layer coated on the current collector, and a lithium supplementary material layer.

[0108] Wherein, the substance coated on the positive electrode active material layer is a mixture of positive electrode active materials, conductive agents, binders, etc., wherein the positive electrode active materials can use one or more of the prior art, a typical but non-limiting example With: LiFePO 4 、LiCoO 2 , LiMn 2 o 4 and layered lithium composite oxide Li 1+x Ni 1-y-z m y N z o 2 One or a combination of them, wherein the layered lithium composite oxide Li 1+x N i1-y-z m y N z o 2 M and N in are respectively one or more of Co, Mn, Al, wherein -0.05<x<0.1, 0<y<2 / 3, 0<z<2 / 3, 0<y+z< 2 / 3.

[0109] The binder is polyvinylidene fluoride (PVDF).

[0110] The conductive agent is one or more of acetylene b...

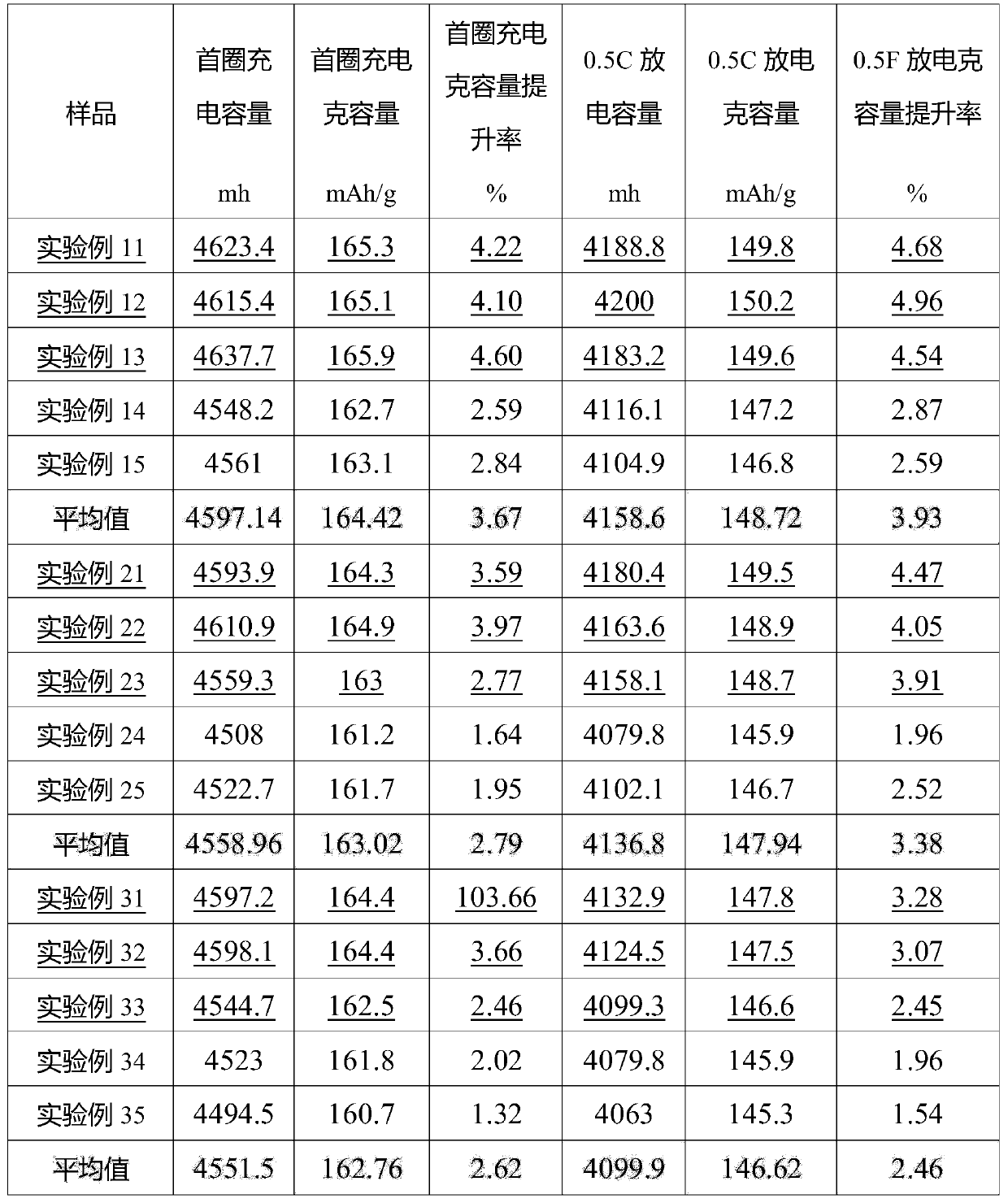

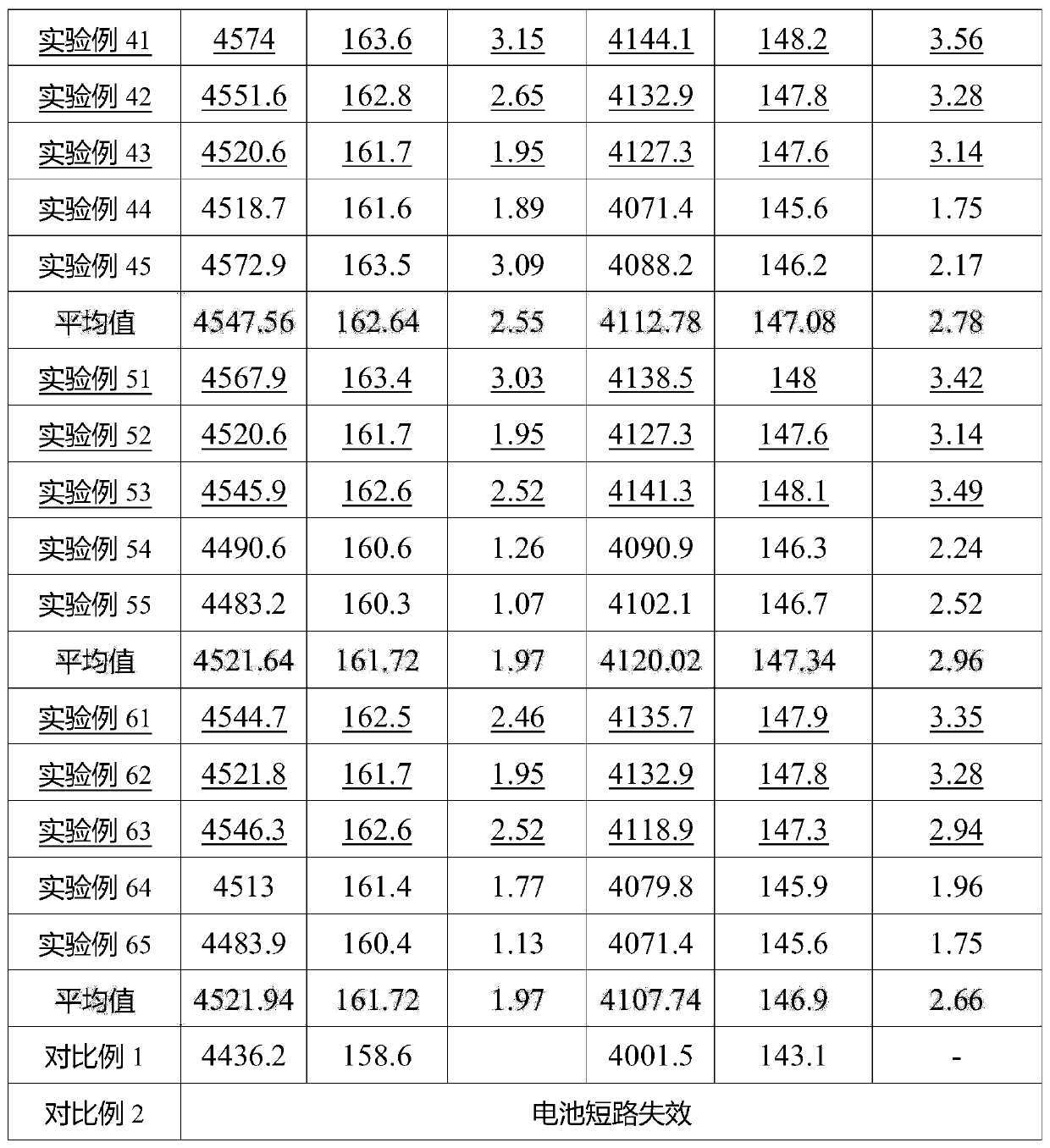

experiment example 11

[0172] 1. Preparation of positive electrode sheet

[0173] 1.1 Preparation of lithium-supplementing material layer

[0174] LiF powder, Co powder, conductive carbon black (SP) and polyvinylidene fluoride (PVDF) were dispersed in N-methylpyrrolidone, and high-energy ball milled for 12 h under nitrogen atmosphere to form a slurry.

[0175] Among them, the mass ratio of LiF:Co:SP:PVDF is: 55:40:2.5:2.5;

[0176] Coat the lithium-supplementing slurry on both sides of the aluminum foil (thickness 12 μm), and then dry it at 90°C for 10 minutes to form a lithium-supplementing material layer on both sides of the aluminum foil. After drying, the coated surface density is 0.22mg / cm2

[0177] 1.2 Formation of positive electrode active material layer

[0178] Disperse lithium ferrous phosphate LiFePO4, conductive carbon black and polyvinylidene fluoride in N-methylpyrrolidone to form positive electrode active material slurry. Wherein, the weight ratio of lithium cobaltate: conductive c...

experiment example 12

[0184] Compared with Experimental Example 11, the only difference is that the mass ratio of LiF:Co:SP:PVDF in this Experimental Example 12 is: wherein, the mass ratio of LiF:Co:SP:PVDF is: 56:41: 1.5:1.5;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com