Novel treatment method of high-salt organic pigment production wastewater

A technology for organic pigments and waste water production, which is applied in the field of water treatment, can solve problems such as non-degradable, difficult to treat pigment waste water to an ideal state, and large impact of production changes, and achieve the effect of solving difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

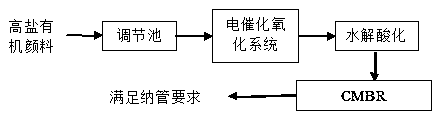

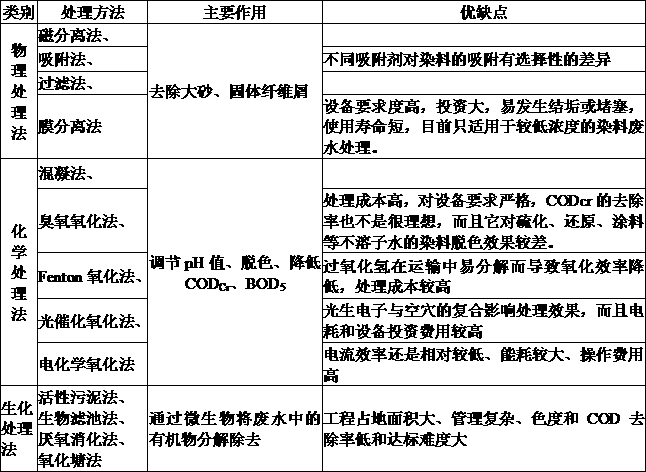

Method used

Image

Examples

Embodiment Construction

[0049] 100m discharged from a workshop of a company 3 / Tian high-salt organic pigment production wastewater adopts the treatment process of the present invention, and the wastewater is treated by the following steps:

[0050] Discharge the high-salt organic pigment production wastewater into the regulating tank 1, homogenize the wastewater through the aeration system at the bottom of the tank, and the average CODCr of the effluent in the regulating tank is 12000mg / L, and then enter the electrocatalytic oxidation system;

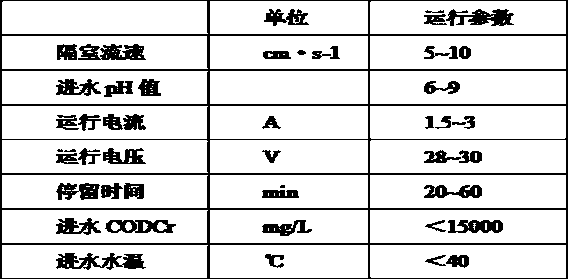

[0051] The operating parameters in the electrocatalytic oxidation system are: compartment flow rate 7 cm s-1, influent pH value 6~9, operating current 3A, operating voltage 28~30 V, residence time 40~60min, electrodes in the system The graphite electrode is used as the cathode, the titanium-coated ruthenium electrode is used as the anode, and the catalytic column is filled with IR series high-efficiency catalysts. The effluent CODCr in the electrocatalytic o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com