Bionic paint and preparation method

A coating and varnish technology, applied in the field of biomimetic coatings and their preparation, can solve problems such as limitations and little research on biomimetic coatings, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

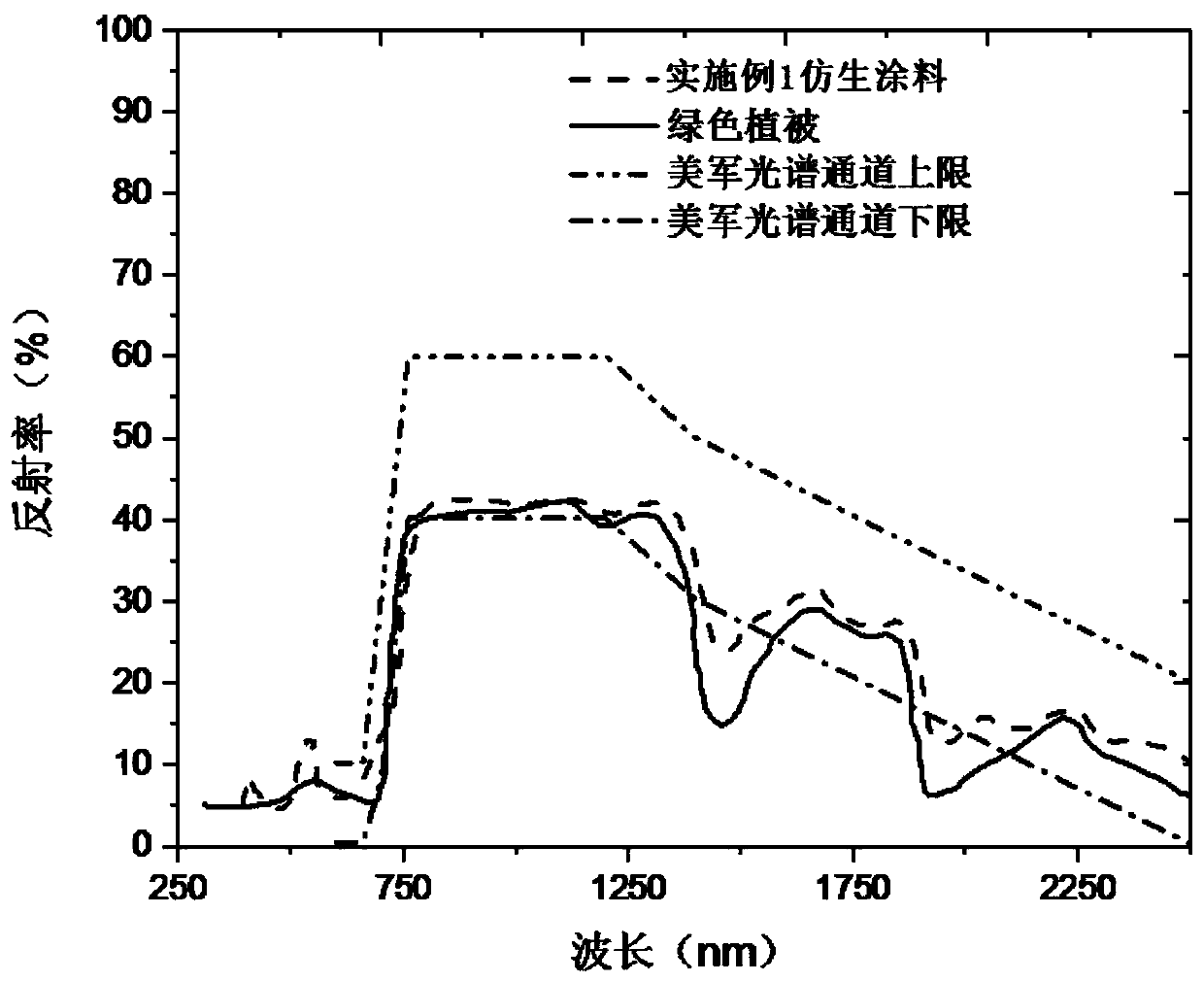

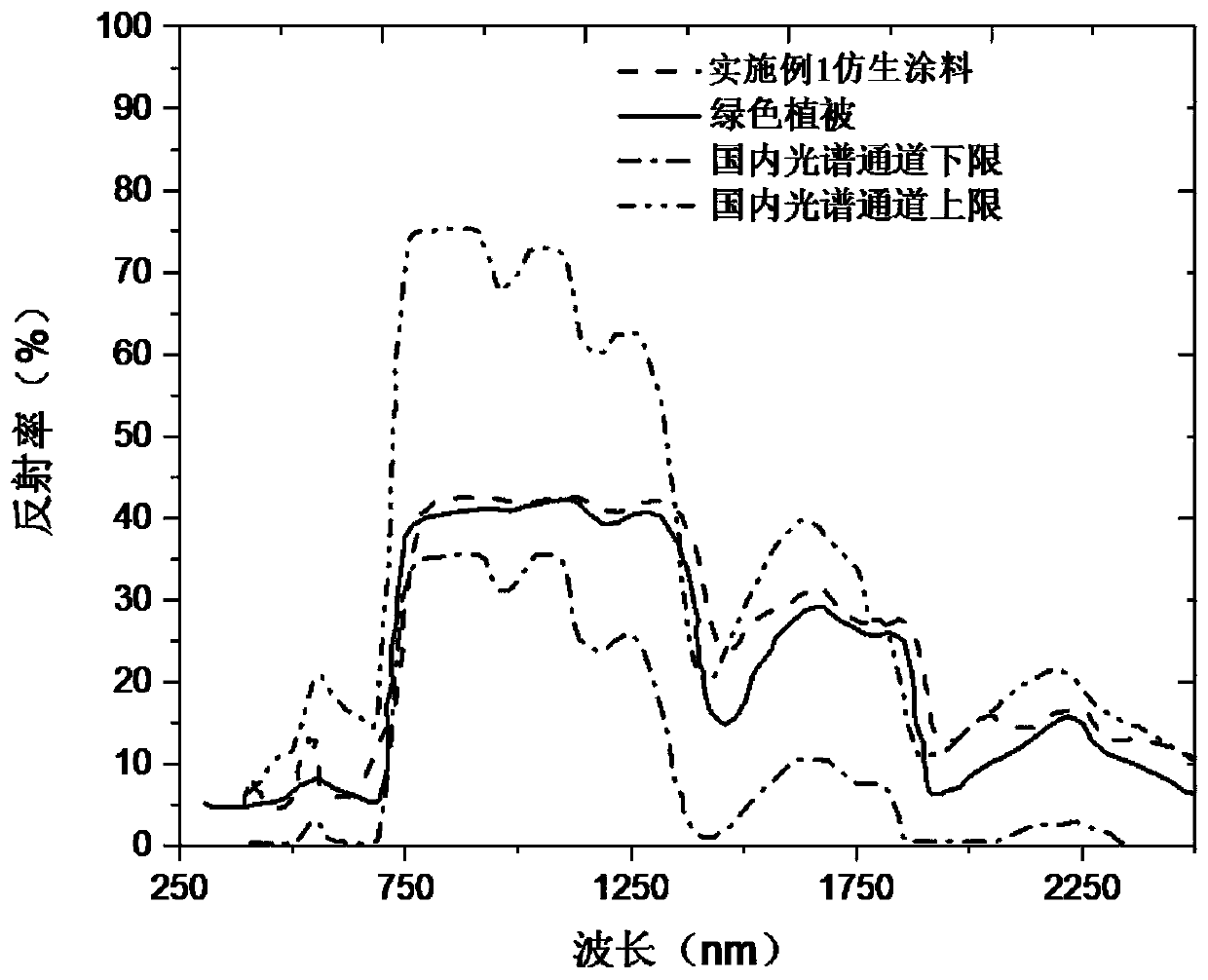

Embodiment 1

[0028] Take by weight 2 parts of acrylic polyurethane varnish, 3 parts of phenolsulfonic acid, 1 part of chromium oxide green, 1 part of benzene, 2 parts of water-wrapped microcapsules, 1 part of epoxy-containing polyacrylate resin, 0.5 part of ophthalmic Diethyl diformate, 0.5 parts of dispersant HT-8163 and 2 parts of emulsified silicone oil; add chromium oxide green to acrylic polyurethane varnish and stir for 20 minutes at room temperature, then add epoxy-containing polyacrylate resin, phthalate di Ethyl ester and dispersant HT-8163 (manufacturer: Nantong Hantai Chemical Co., Ltd.) continue stirring at room temperature for 5 minutes, then add water-encapsulated microcapsules and continue stirring for 8 minutes, then add phenolsulfonic acid and emulsified silicone oil and stir for 10 minutes, and finally add benzene and stir for 2 minutes Prepare biomimetic paint.

Embodiment 2

[0030] Take by weight 3 parts of alkyd resin, 1 part of amino resin, 1 part of iron oxide green, 2 parts of toluene, 4 parts of water-wrapped microcapsules, 0.2 part of epoxy-containing polyacrylate resin, 0.3 part of phthalate Dioctyl formate, 0.5 parts of dispersant HT-8163 and 1 part of polyoxypropylene glyceryl ether; Add chromium oxide green to alkyd resin and stir at room temperature for 22 minutes, then add epoxy-containing polyacrylate resin, phthalate Dioctyl formate and dispersant HT-8163 (manufacturer: Nantong Hantai Chemical Co., Ltd.) continued to stir at room temperature for 7 minutes, then added water-wrapped microcapsules and continued to stir for 10 minutes, then added amino resin and polyoxypropylene glyceryl ether and stirred for 13 minutes, and finally Add toluene and stir for 4 minutes to prepare the biomimetic coating.

Embodiment 3

[0032] Take by weight 4 parts of polyurethane paint, 4 parts of hydroxyl curable polyurethane, 2 parts of titanium chrome brown, 2 parts of xylene, 8 parts of water-wrapped microcapsules, 2 parts of polyacrylate resin containing epoxy groups , 1 part of tricresyl phosphate, 1 part of dispersant HT-8163 and 3 parts of polydimethylsiloxane; add titanium chrome yellow to polyurethane paint and stir for 30 minutes at room temperature, then add epoxy-containing Polyacrylate resin, tricresyl phosphate, dispersant HT-8163 (manufacturer: Nantong Hantai Chemical Co., Ltd.) Continue stirring at room temperature for 10 minutes, then add water-wrapped microcapsules and continue stirring for 12 minutes, then add hydroxyl curable polyurethane and poly The methyl siloxane was stirred for 15 minutes, and finally xylene was added and stirred for 5 minutes to prepare the biomimetic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com