Anti-rust and weather-resistant brush-coating macromolecular material as well as preparation method and application thereof

A polymer material, brushing technology, used in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of poor rust resistance, fire resistance, weather resistance and water resistance, complex construction process, easy peeling, etc. The effect of large-scale industrial production, good application prospects and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

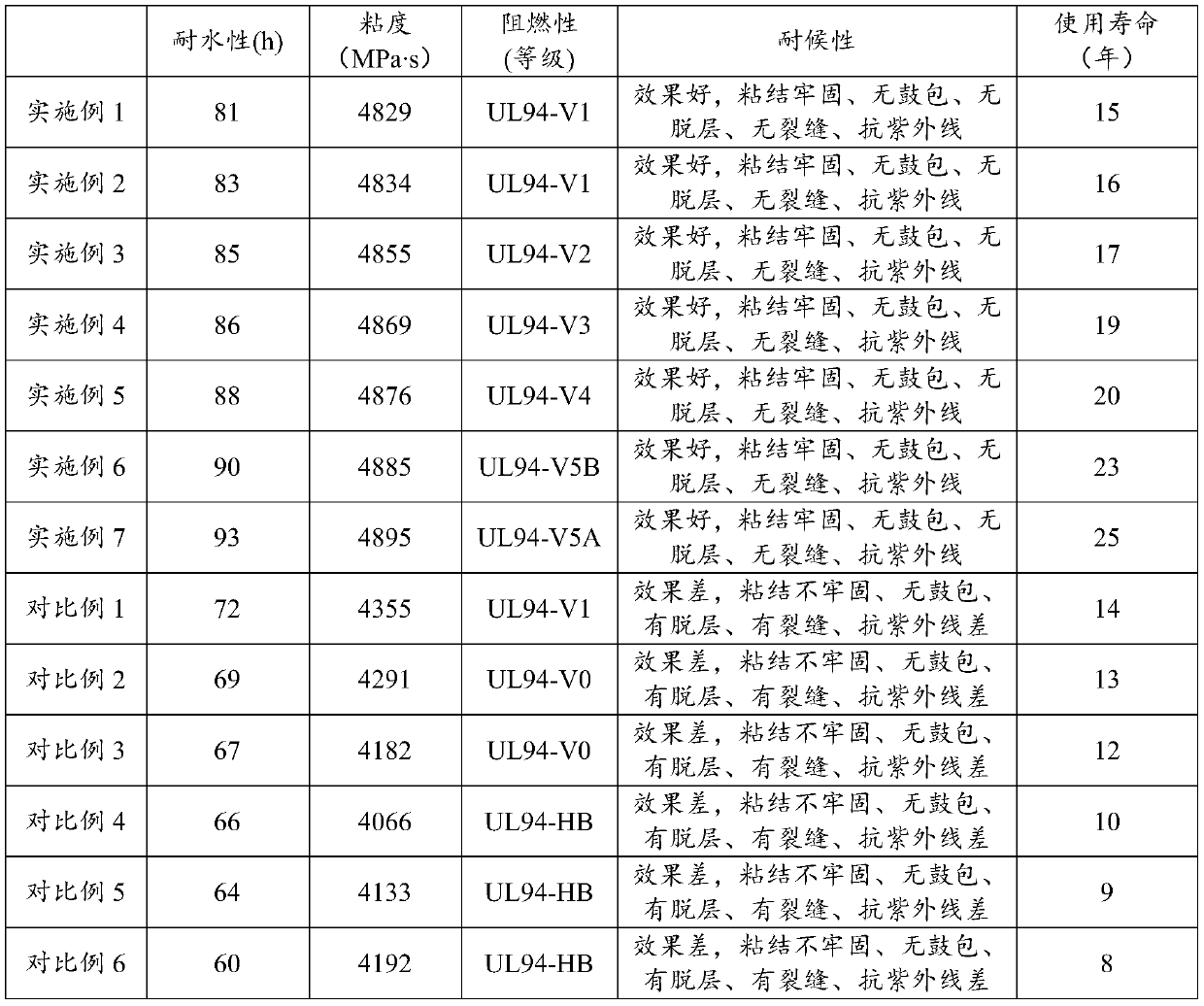

Examples

preparation example Construction

[0057] According to a second aspect of the present invention, the present invention provides a method for preparing a rust-proof and weather-resistant brush-coated polymer material, comprising the following steps:

[0058] (a) 107 silicone rubber, nano silicon powder, the first silane coupling agent and optional flame retardant are mixed uniformly to obtain agent A;

[0059] (b) Mix the second silane coupling agent, ethyl silicate and organotin evenly, and obtain agent B after heating and reacting;

[0060] (c) Mix agent A and agent B evenly to obtain an anti-rust and weather-resistant brush-coating polymer material.

[0061] The preparation method of the rust-proof and weather-resistant brush-coating polymer material provided by the invention has simple process, simple and convenient operation, and is easy for large-scale industrial production.

[0062] In the present invention, by preparing agent A and agent B and controlling the ratio of the two, the rust-proof and weather...

Embodiment 1

[0081] The present embodiment provides a kind of anti-rust and weather-resistant brush coating polymer material, including the following raw materials in parts by mass: 70 parts of 107 silicone rubber, 30 parts of nano silicon powder, 0.5 part of vinylmethyldiethoxysilane, 1.5 parts of aminopropyltriethoxysilane, 1 part of ethyl silicate, 1 part of organotin and 20 parts of aluminum hydroxide.

Embodiment 2

[0083] The present embodiment provides a kind of anti-rust and weather-resistant brush coating polymer material, including the following raw materials in parts by mass: 130 parts of 107 silicon rubber, 10 parts of nano silicon powder, 2 parts of vinylmethyldiethoxysilane, 0.3 parts of aminopropyltriethoxysilane, 5 parts of ethyl silicate, 0.2 parts of organotin and 60 parts of aluminum hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com