Foaming drainage aid and preparation method thereof

A technology of foaming and drainage aids and active agents, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of lack of foam stabilizers, reduce the adhesion of construction residual liquid, reduce fluid loss, etc., and achieve Good anti-condensate performance, good stability, and good flowback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

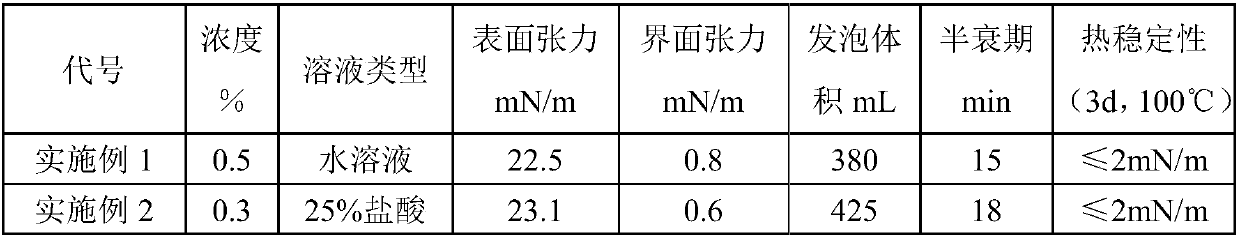

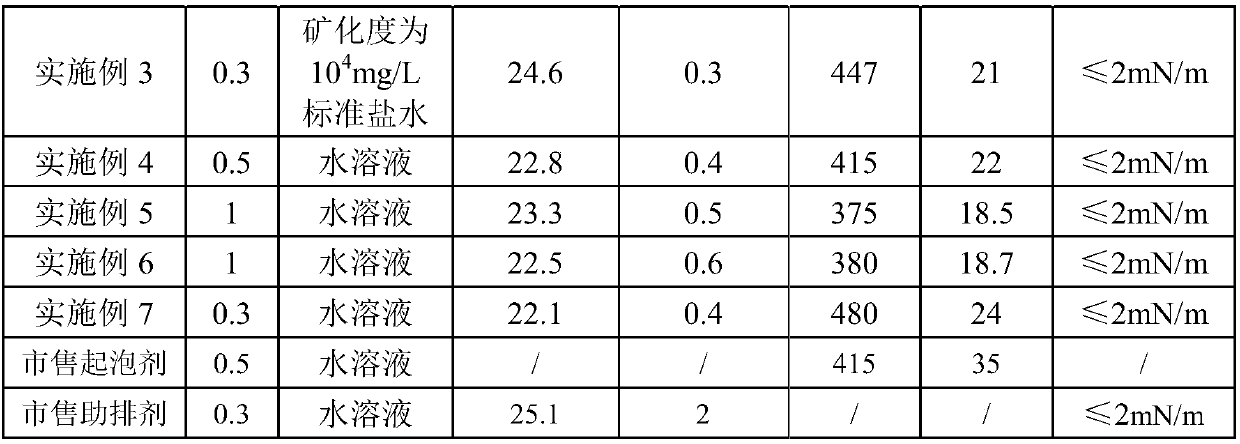

Examples

Embodiment 1

[0024] The foaming aid of this embodiment is composed of the following components by mass percentage: cationic surfactant 8%, nonionic surfactant 2%, amine oxide amphoteric surfactant 10%; fluorocarbon surfactant 1% , auxiliary agent 15%, foam stabilizer 7%, the balance is water; cationic surfactant is dodecyl dimethyl benzyl ammonium chloride, nonionic surfactant is C 14 Fatty alcohol polyoxyethylene ether, amine oxide amphoteric surfactant is dodecyl dimethyl amine oxide, fluorocarbon surfactant is perfluoroalkyl ether quaternary ammonium salt cationic fluorocarbon surfactant, auxiliary agent is ethyl Diol, foam stabilizer is polypeptide.

[0025] The preparation method of the foaming and drainage aid in this embodiment comprises the following steps: take the components of the formulation amount, mix the non-ionic surfactant and the auxiliary agent, stir at room temperature until it dissolves evenly, and then add the fluorocarbon surfactant Agent and cationic surfactant, st...

Embodiment 2

[0027] The foaming and drainage aid of this embodiment is composed of the following components by mass percentage: cationic surfactant 8%, nonionic surfactant 5%, amine oxide amphoteric surfactant 15%; fluorocarbon surfactant 0.5% , auxiliary agent 20%, foam stabilizer 6%, the balance is water; cationic surfactant is octadecyl dimethyl benzyl ammonium chloride, nonionic surfactant is alkylphenol polyoxyethylene ether op- 10. The amine oxide amphoteric surfactant is octadecyl dimethyl amine oxide, the fluorocarbon surfactant is perfluoroalkyl ether quaternary ammonium salt cationic fluorocarbon surfactant, the auxiliary agent is ethylene glycol, and the foam is stabilized The agent is a polypeptide.

[0028] The preparation method of the foaming and drainage aid of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0030] The foaming and drainage aid of this embodiment is composed of the following components by mass percentage: cationic surfactant 8%, nonionic surfactant 5%, amine oxide amphoteric surfactant 12%; fluorocarbon surfactant 3% , auxiliary agent 18%, foam stabilizer 5%, the balance is water; cationic surfactant is dodecyl dimethyl benzyl ammonium chloride, nonionic surfactant is alkylphenol polyoxyethylene ether op- 10. The amine oxide amphoteric surfactant is octadecyl dimethyl amine oxide, the fluorocarbon surfactant is ethoxylated nonionic fluorocarbon surfactant, the auxiliary agent is glycerol, and the foam stabilizer is Polyacrylamide.

[0031] The preparation method of the foaming and drainage aid of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com