Sulfonated carbon quantum dots, preparation method thereof and application thereof serving as catalyst in preparing 5-hydroxymethyl furaldehyde

A carbon quantum dot and a technology for quantum dots are applied to sulfonated carbon quantum dots, their preparation and their application as a catalyst in the preparation of 5-hydroxymethylfurfural, which can solve the problem of high temperature and achieve good dispersibility and good contact. , the preparation method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Immerse 0.4g camphor leaves in a concentration of 1wt% hydrogen peroxide solution, the mass ratio of biomass to hydrogen peroxide is 1:1.2, hydrothermal treatment at a temperature of 140°C for 12h, and synthesize a carbon quantum dot dispersion; The carbon quantum dot dispersion was fully dialyzed, and a solid sample was obtained after freeze-drying.

[0035] The solid sample was dissolved in 98% concentrated sulfuric acid, sulfonated at 100° C. for 2 hours, then fully dialyzed, and sulfonated carbon quantum dots were obtained after freeze-drying.

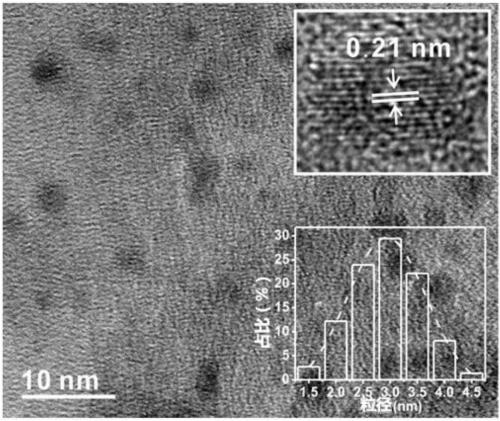

[0036] The transmission electron micrograph and particle size distribution of the sulfonated carbon quantum dots prepared above are as follows: figure 1 As shown, it is shown that the prepared particle size is 1.5nm-4.5nm. figure 1 The upper right corner is an enlarged view of a sulfonated carbon quantum dot, which shows that the sulfonated carbon quantum dot has obvious lattice fringes, and the interplanar spacing is 0.21n...

Embodiment 2

[0044] Immerse 0.6g camphor leaves in a concentration of 2wt% hydrogen peroxide solution, the mass ratio of biomass to hydrogen peroxide is 1:2, hydrothermal treatment at a temperature of 160°C for 10h, and synthesize a carbon quantum dot dispersion; The carbon quantum dot dispersion was fully dialyzed, and a solid sample was obtained after freeze-drying.

[0045]The solid sample was dissolved in 98% concentrated sulfuric acid, sulfonated at a temperature of 100°C for 6 hours to obtain a sulfonated carbon quantum dot solution, then fully dialyzed, and freeze-dried to obtain the sulfonated carbon quantum dots.

[0046] The transmission electron micrograph and particle size distribution of the above-mentioned sulfonated carbon quantum dots are similar figure 1 As shown, it is shown that the obtained particle size is 2.0nm-3.5nm, and similar to graphene, containing sp 2 and sp 3 carbon.

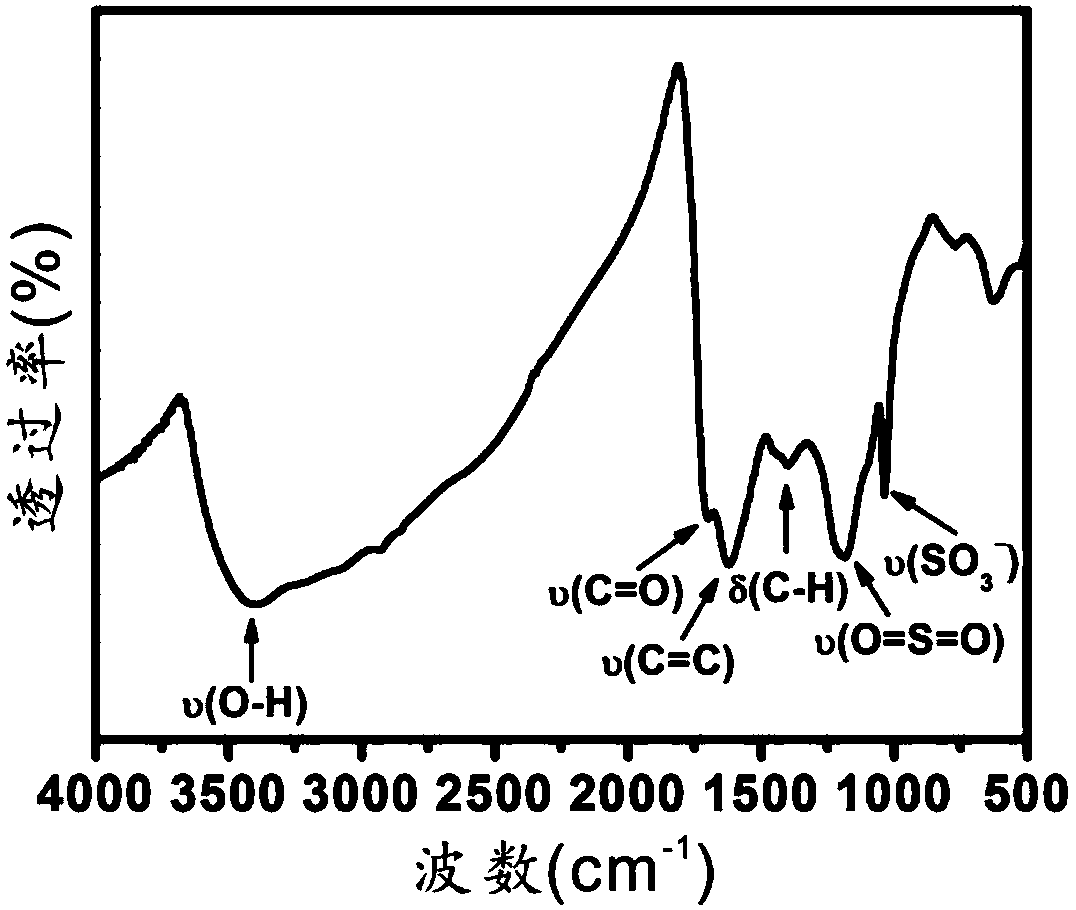

[0047] The infrared spectrum of the sulfonated carbon quantum dots prepared above is simi...

Embodiment 3

[0050] Immerse 0.8g camphor leaves in a hydrogen peroxide solution with a concentration of 3wt%, the mass ratio of biomass to hydrogen peroxide is 1:3, and hydrothermally treat it at a temperature of 180°C for 12h to synthesize a carbon quantum dot dispersion; The quantum dot dispersion was fully dialyzed and freeze-dried to obtain a solid sample.

[0051] The solid sample was dissolved in 98% concentrated sulfuric acid, and sulfonated at 140°C for 12 hours to obtain a sulfonated carbon quantum dot solution, which was then fully dialyzed and freeze-dried to obtain the sulfonated carbon quantum dots.

[0052] The transmission electron micrograph and particle size distribution of the above-mentioned sulfonated carbon quantum dots are similar figure 1 As shown, it is shown that the obtained particle size is 2.0nm-4.5nm, and is similar to graphene, containing sp 2 and sp 3 carbon.

[0053] The infrared spectrum of the sulfonated carbon quantum dots prepared above is similar to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com