Waste rubber/plastic regenerated product set and preparation method thereof

A technology of waste rubber and waste plastics, which is applied in the direction of product, plastic recycling, and liquid hydrocarbon mixture preparation, etc., which can solve the problems of white ash not being used as resources, dispersion, and unimpeded connection, and meet supply and demand/market price effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

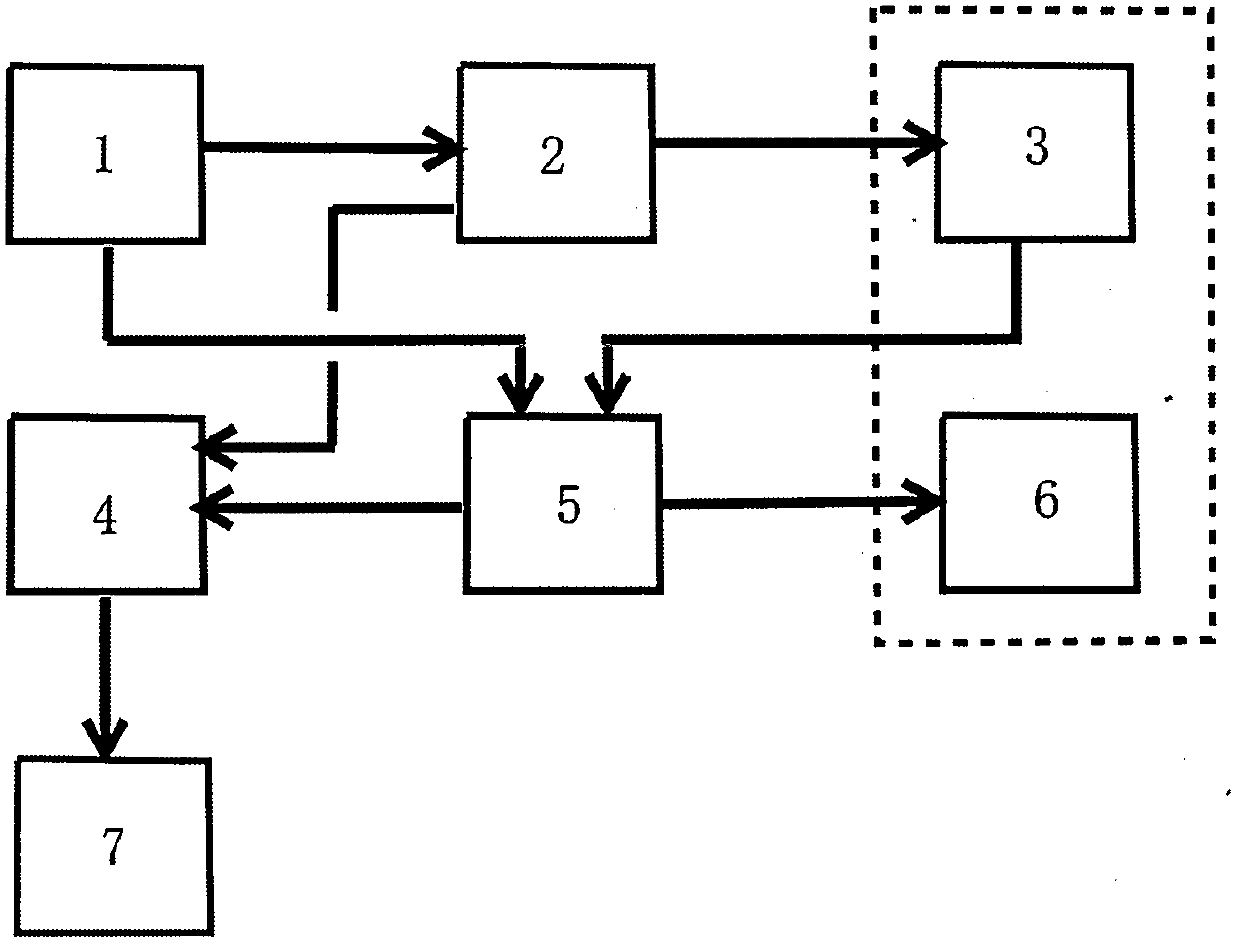

Image

Examples

Embodiment 1

[0133] A collection of waste rubber / plastic regenerated products and its production method, the collection is characterized by: a subset A of waste rubber or / and waste plastics obtained by thermal cracking, or / and a product obtained by non-thermal cracking Product subset B; said B, including blending A, or / and using the conversion energy of A, and then processing through a known combination method, the obtained recycled rubber / plastic product subset B; or / and in said B , also comprising a core / shell of recycled rubber or / and plastic;

[0134] The subset A, which at least comprises A1 or / and A6 or / and A7 or / and A8 or / and A9, or a combination with any or more of A2, A3, A4, A5, A10:

[0135] A1——waste rubber / plastic pyrolysis heavy oil that can be used as rubber / plastic softener or tackifier, A2——waste rubber / waste plastic pyrolysis heavy oil that can be used as rubber / plastic tackifier, A3——can be Depurified light oil as fuel, A4—combustible gas that can be used as fuel, A5—py...

Embodiment 2

[0176] The preparation method of "subset A" described in Example 1 is characterized in that: the raw materials of subset A are prepared by any one or a combination of the above materials as follows:

[0177] Discarded tires from motor vehicles or non-motor vehicles, plastic turf used in sports fields, plastic runways used in sports fields, plastic films discarded from recycled pulp production, rubber or / and plastic waste scraps discarded by shoe manufacturers, Waste trim or / and scorched materials or / and defective products discarded by rubber product enterprises;

[0178] Adopt commercially available / self-made thermal cracking equipment for the raw material to carry out heating and dry distillation, in order to obtain the A1 described in Example 1, its preparation method is characterized in that: carry out the following 2-1 or and 2-2 to 2-5 to the distillate gas Any or a combination of the above:

[0179] 2-1. For the pyrolysis dry distillation gas, use distillation or rectif...

Embodiment 3

[0215] The method for preparing sub-set B described in Example 1 is characterized in that: the raw materials of sub-set B are obtained by making any one or a combination of the above materials as follows:

[0216] Discarded tires from motor vehicles or non-motor vehicles, plastic turf used in sports fields, plastic runways used in sports fields, plastic films discarded from recycled pulp production, rubber or / and plastic waste scraps discarded by shoe manufacturers, Waste trim or / and scorched materials or / and defective products discarded by rubber product enterprises;

[0217] The raw materials are processed by a known combined process, but the softener or tackifier in the formulations involved in B1 to B10 is partially or entirely used in A1 described in Example 1; or / and, in B1 to B10 The filler composition in the formula involved part or all uses the combination of A6 or / and A7 or / and A8 described in Example 1; or / and, the energy source of electricity / heat / steam used in B1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com