A high-niobium austenitic heat-resistant steel with high structural stability at 700°C and its preparation method

An austenitic heat-resistant steel and stability technology, applied in the field of high-temperature metal structural materials, can solve problems such as poor organizational stability, increased unit construction costs, and inability to meet service performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

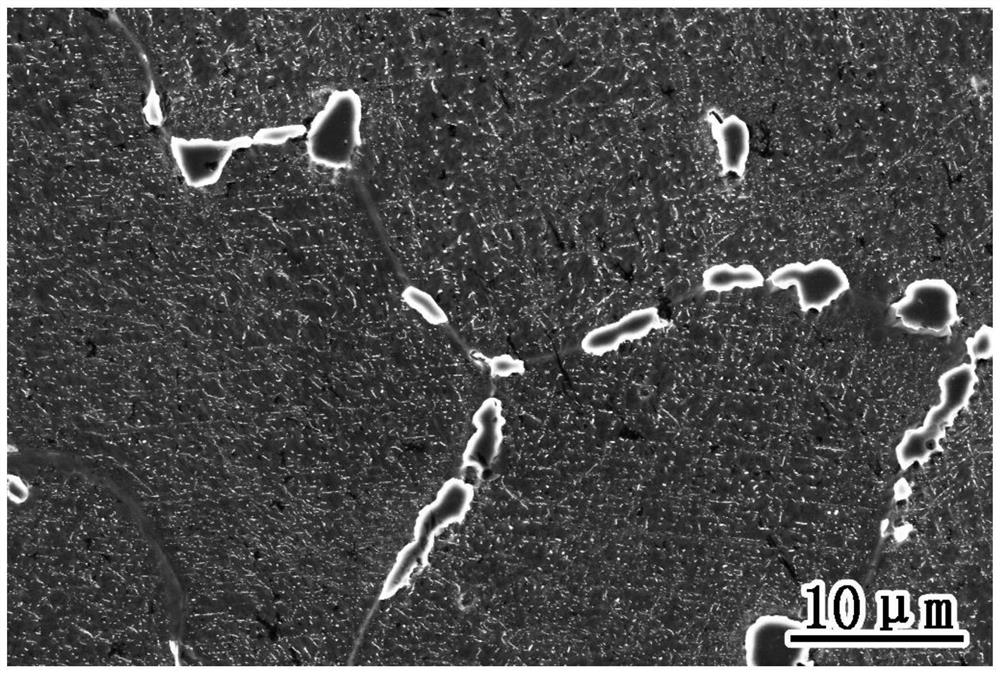

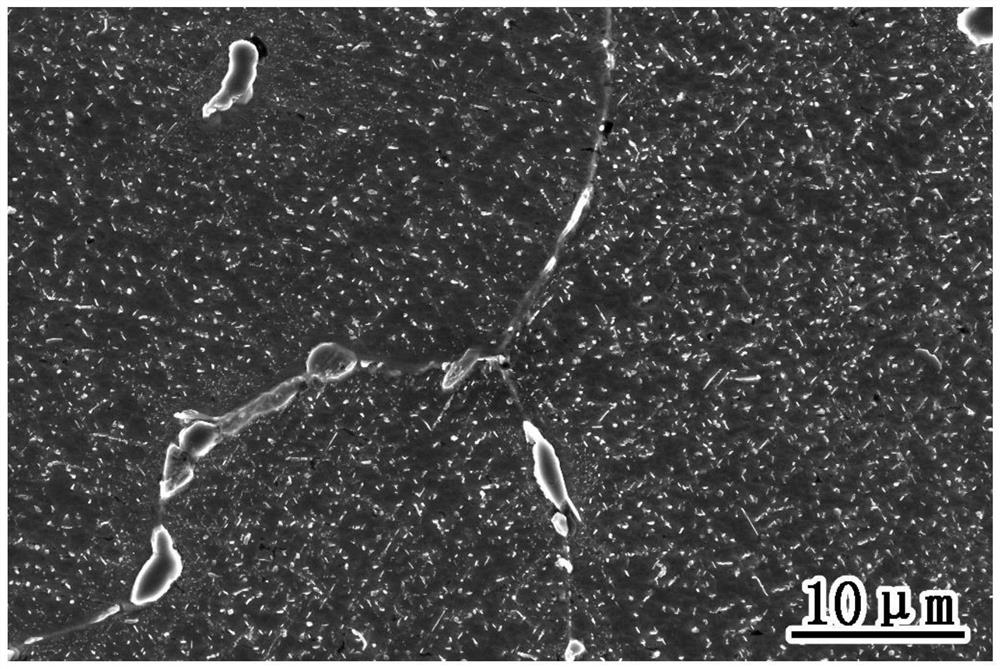

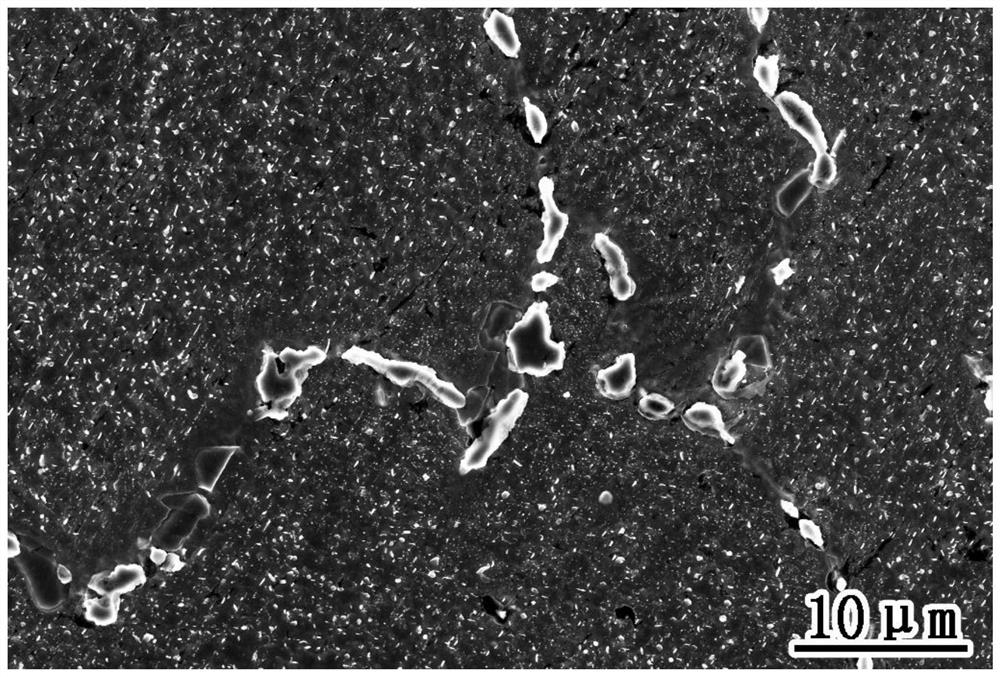

Image

Examples

Embodiment 1

[0043] 1) Alloy preparation.

[0044] The specific chemical composition (unit: mass percentage) of the above alloy at the time of preparation is Cr: 21.5%, Ni: 18%, Nb: 1.7%, C: 0.04%, N: 0.1%, Co: 0.9%, Si: 0.4% , Mn:

[0045] 0.03%, B: 0.002%, Zr: 0.002%, and the balance is Fe.

[0046] After considering the burning loss, the batching is completed, argon gas is introduced into the vacuum arc melting furnace as a protective gas, and a 150g button ingot with uniform alloy composition is obtained by electromagnetic stirring and turning. In order to eliminate macroscopic and microscopic segregation, a homogenization annealing treatment is carried out at 1100-1260°C for 20-35 hours, so that the alloy elements can be diffused as fully and uniformly as possible. After the homogenization annealing treatment, in order to make a large amount of Nb, C and N elements in the primary MX phase dissolve back into the matrix as much as possible, the alloy is subjected to solution treatment...

Embodiment 2-7

[0056] Table 2 shows the specific chemical composition of the alloys of Examples 2-7 of the present invention. Through the preparation and analysis of these alloys, it is found that the corresponding microstructure stability and mechanical properties are in line with the conditions and requirements applied to the steam pipeline of the 650 ℃ ultra-supercritical supercritical super / reheater.

[0057] Table 2 Chemical composition of Examples 2-7 of the present invention (unit is mass percent, balance is Fe)

[0058] alloy 2# 3# 4# 5# 6# 7# Cr 18 18.5 19 20 21 22 Ni 17 17.5 19 19.5 21 22 Nb 1.1 1.6 1.2 1.5 2 1 C 0.01 0.02 0.05 0.06 0.07 0.08 N 0.01 0.05 0.08 0.10 0.12 0.15 co 0.1 0.3 0.5 0.75 0.8 1 Si 0.3 0.34 0.4 0.43 0.52 0.75 mn 0.1 0.15 0.2 0.25 0.3 0.5 B 0.001 0.002 0.002 0.002 0.003 0.003 Zr 0.001 0.002 0.002 0.002 0.002 0.003

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com