Technology for preparing hollow fiber based on electrostriction material

An electrostrictive material and hollow technology, applied in the direction of fiber type, fiber processing, hollow filament manufacturing, etc., can solve the problems of affecting the telescopic performance of electrostrictive materials, low conversion rate of electrical energy conversion and mechanical energy conversion, and increasing use costs, etc. The effect of accelerated solidification time, high power conversion rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

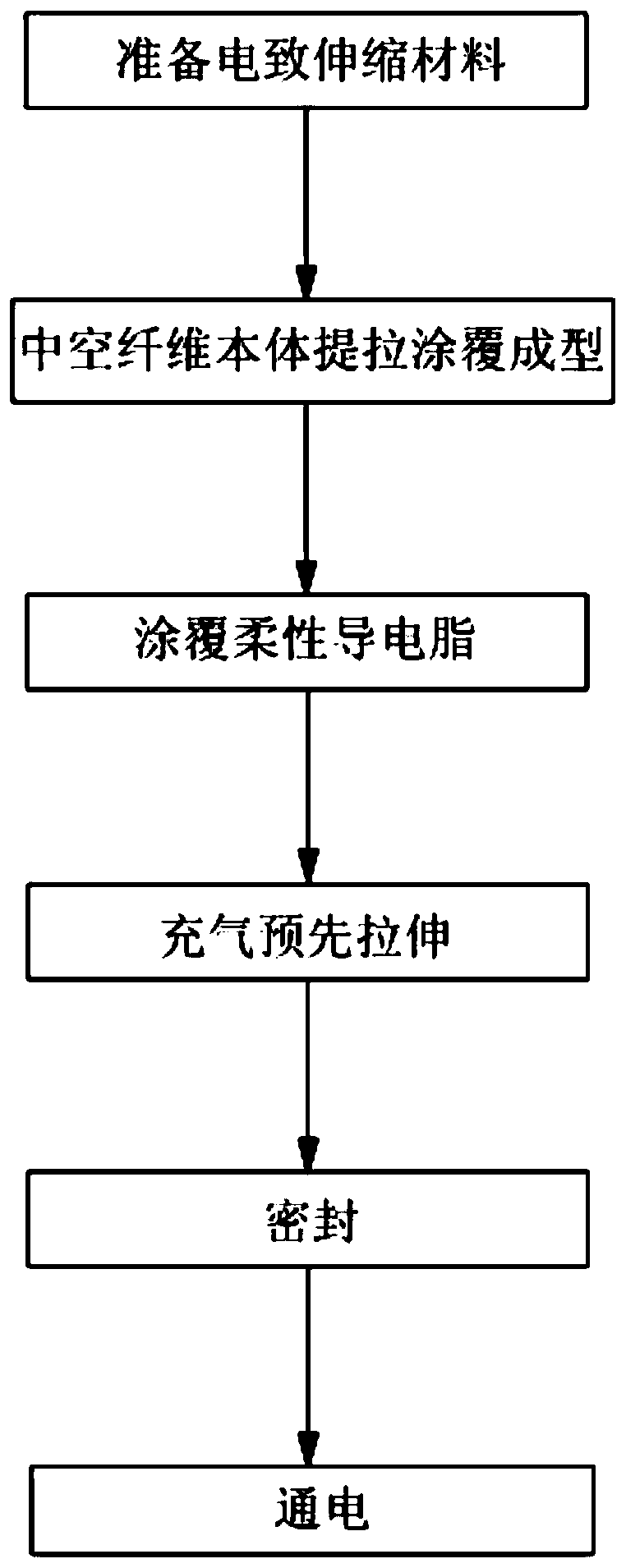

[0039] A process for preparing hollow fibers based on electrostrictive materials, comprising the steps of:

[0040] (1) Prepare the electrostrictive material:

[0041] The prepared liquid styrene-butadiene-styrene block copolymer is packed in a container for subsequent use;

[0042](2) Hollow fiber body pulling coating molding:

[0043] a. The liquid electrostrictive material in the container in step (1) is pulled and coated with the pulling forming carrier, and at the same time, the lifting forming carrier is pulled by the lifting mechanism to rise at a certain speed, and the pulling and coating is carried out, so that the liquid The electrostrictive material is wrapped on the pulling forming carrier, and the pulling forming carrier can be made of iron wire. The pulling forming carrier is coated with a layer of silicone oil before pulling and coating, so that the liquid electrostrictive material can be removed from the pulling forming carrier after solidification. Falling o...

Embodiment 2

[0051] A process for preparing hollow fibers based on electrostrictive materials, comprising the steps of:

[0052] (1) Prepare the electrostrictive material:

[0053] Prepared liquid ethylene-vinyl acetate copolymer is dressed in a container for subsequent use;

[0054] (2) Hollow fiber body pulling coating molding:

[0055] a. The liquid electrostrictive material in the container in step (1) is pulled and coated with the pulling forming carrier, and at the same time, the lifting forming carrier is pulled by the lifting mechanism to rise at a certain speed, and the pulling and coating is carried out, so that the liquid The electrostrictive material is wrapped on the pulling forming carrier, and the pulling forming carrier can be made of iron wire. The pulling forming carrier is coated with a layer of silicone oil before pulling and coating, so that the liquid electrostrictive material can be removed from the pulling forming carrier after solidification. Falling off; the hoi...

Embodiment 3

[0063] A process for preparing hollow fibers based on electrostrictive materials, comprising the steps of:

[0064] (1) Prepare the electrostrictive material:

[0065] The prepared liquid thermoplastic polyurethane elastomer rubber is filled in a container;

[0066] (2) Hollow fiber body pulling coating molding:

[0067] a. The liquid electrostrictive material in the container in step (1) is pulled and coated with the pulling forming carrier, and at the same time, the lifting forming carrier is pulled by the lifting mechanism to rise at a certain speed, and the pulling and coating is carried out, so that the liquid The electrostrictive material is wrapped on the pulling forming carrier, and the pulling forming carrier can be made of iron wire. The pulling forming carrier is coated with a layer of silicone oil before pulling and coating, so that the liquid electrostrictive material can be removed from the pulling forming carrier after solidification. Falling off; the hoisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com