A kind of preparation method of anti-counterfeiting label with micro-nano structure

A technology of anti-counterfeiting labels and micro-nano structures, which is applied in the direction of record carriers, identification devices, and instruments used by machines, can solve the problems of unfavorable long-term storage, unfavorable, and inconvenient use, and achieve rich raw materials, novel structures, and safety factors. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

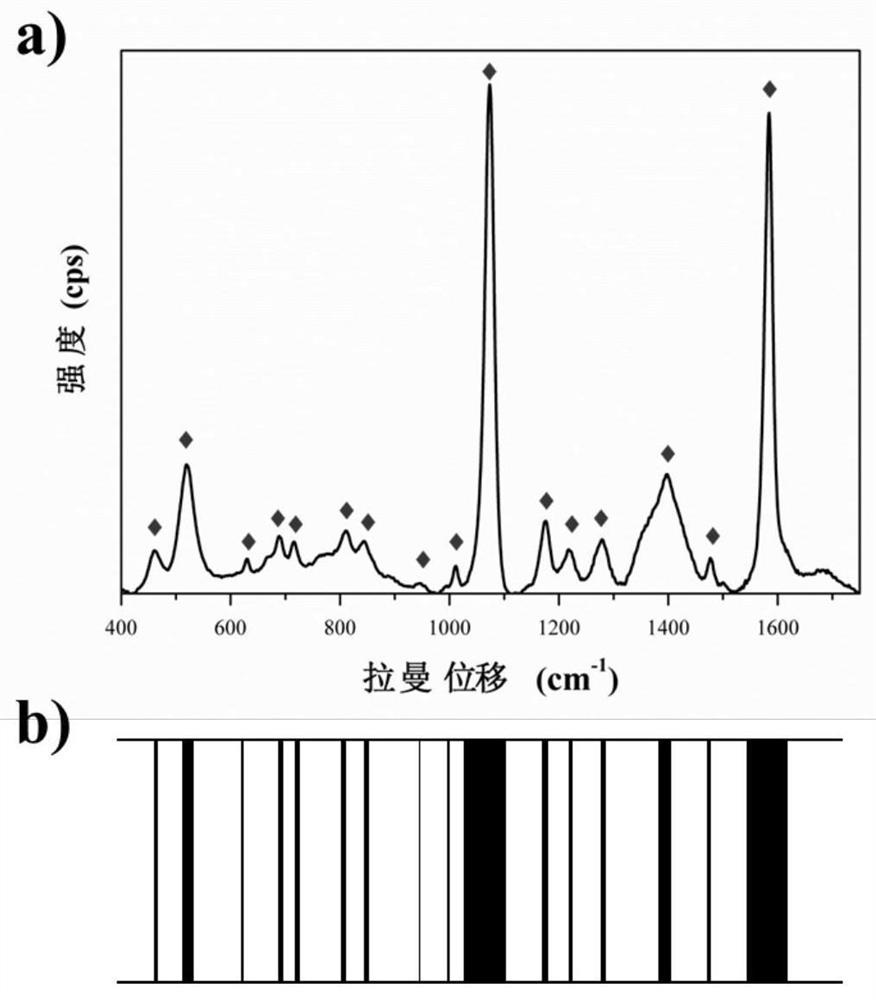

[0023] (1) Preparation of 12 wt% PMMA and P4VP spinning fluid, the mass ratio of the two polymers is 1: 2, the solvent is acetone and DMF mixed solvent, the volume ratio is 2: 1. The parameters of the static spinning machine are as follows: 25 kV positive pressure, negative pressure -5 kV, pumping speed 0.20mm / min, and receive distance 20cm.

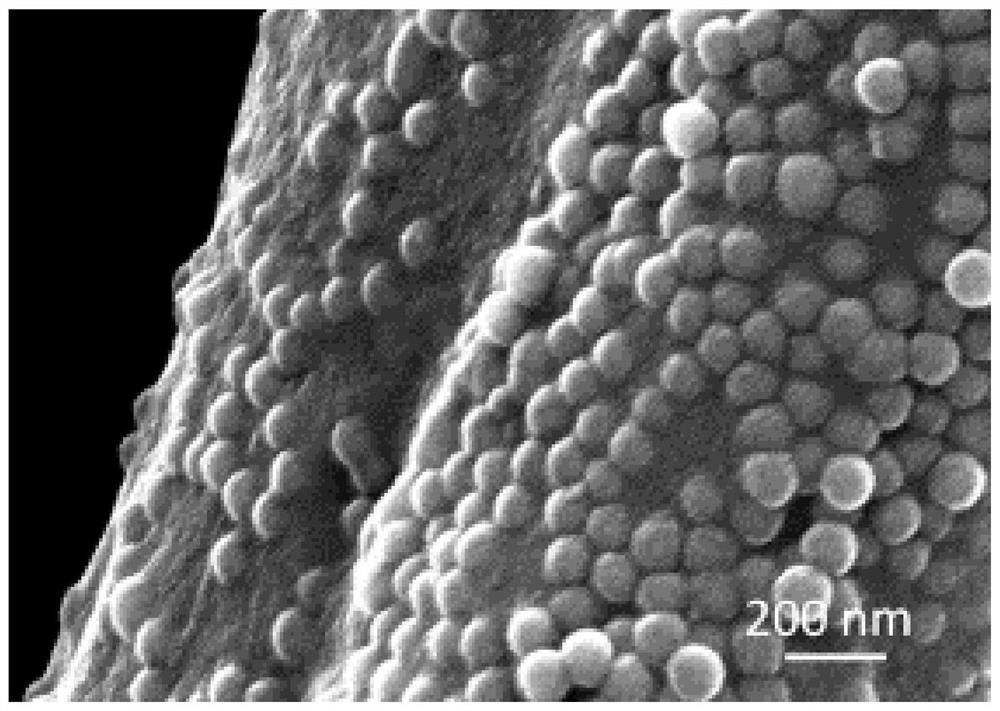

[0024] (2) Au NPS for the preparation of about 40 nm was prepared, and 0.01 mm 4-MBA was modified on the surface of the Au NPS, and silica was coated in the surface of the Au NPS by a sol gel method, wherein the volume of water and isopropyl alcohol. The ratio is 1: 5, gets a particle size of about 60 nm au @ Sio 2 NPS, the coating thickness is about 10 nm.

[0025] (3) Au @ Sio concentrations of 200 μmol / L 2 NPS was dispersed in a mixed solution of pH = 2 and ammonium acetate, 2 cm × 2 cm electrostatic spinning fibers were immersed in the above solution, the process remained in a stationary state for 10 min, so that electrostatic spinni...

Embodiment 2

[0029] (1) The 20 wt% PMMA and P4VP spinning fluids are formulated. The mass ratio of the two polymers is 2: 1, the solvent is acetone and DMF mixed solvent, the volume ratio is 1: 3. The parameters of the electrostatic spinning machine are as follows: positive pressure 18kV, negative pressure -1kv, pumping speed 0.45mm / min, and receive distance 15cm.

[0030] (2) Preparation of Au NPS for a particle size of about 60 nm, modified 8.9 mM Mbia in the surface of the Au NPS, coated with silica in the surface of the Au NPS by a sol gel method, wherein the volume ratio of water and isopropanol is 2.5: 1, get the particle size of about 100 nm Au @ Sio 2 NPS, the coating thickness is about 20 nm.

[0031] (3) Au @ Sio in 200 pmol / L 2NPS was dispersed in a mixed solution of pH = 4 and ammonium acetate, and 2 cm × 2 cm electrostatic spinning fibers were immersed in the above solution, the process remained in the oscillating state for 10 min, so that electrospinning fibers and Au @ SiO 2...

Embodiment 3

[0035] (1) Handling 38 wt% of PMMA and P4VP spinning fluid, the mass ratio of the two polymers is 1: 2, the solvent is acetone and DMF mixed solvent, the volume ratio is 4: 1. The parameters of the static spinning machine are as follows: positive pressure 15kV, negative pressure -1kv, pumping speed 0.25mm / min, and receive distance 30cm.

[0036] (2) Au NPS having a particle diameter of about 80 nm was prepared, and 5 mm 4-MBA and 5 mM MbIa (volume ratio 1:10) were prepared to be modified in the surface of the Au NPS, and silica was coated in Au by a sol gel method. The surface of the NPS, wherein the volume ratio of water and isopropyl alcohol is 5: 1, and the particle size is approximately 200 nm Au @ SiO 2 NPS, the coated thickness is about 60 nm.

[0037] (3) Put the concentration of 1 pmol / Lau@sio 2 NPS was dispersed in a mixed solution of pH = 9 and ammonium acetate, 2 cm × 2 cm electrospinning fibers were immersed in the above solution, the process remained in the vortex s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com