Preparation method of supermolecule hollow fiber membrane

A supramolecular and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low strength and poor pollution resistance of hollow fiber membranes, increase hydrophilicity and overcome easy peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 2 groups of supramolecular reinforcement reinforced liquid crystal supramolecular / polyethersulfone hollow fiber membrane:

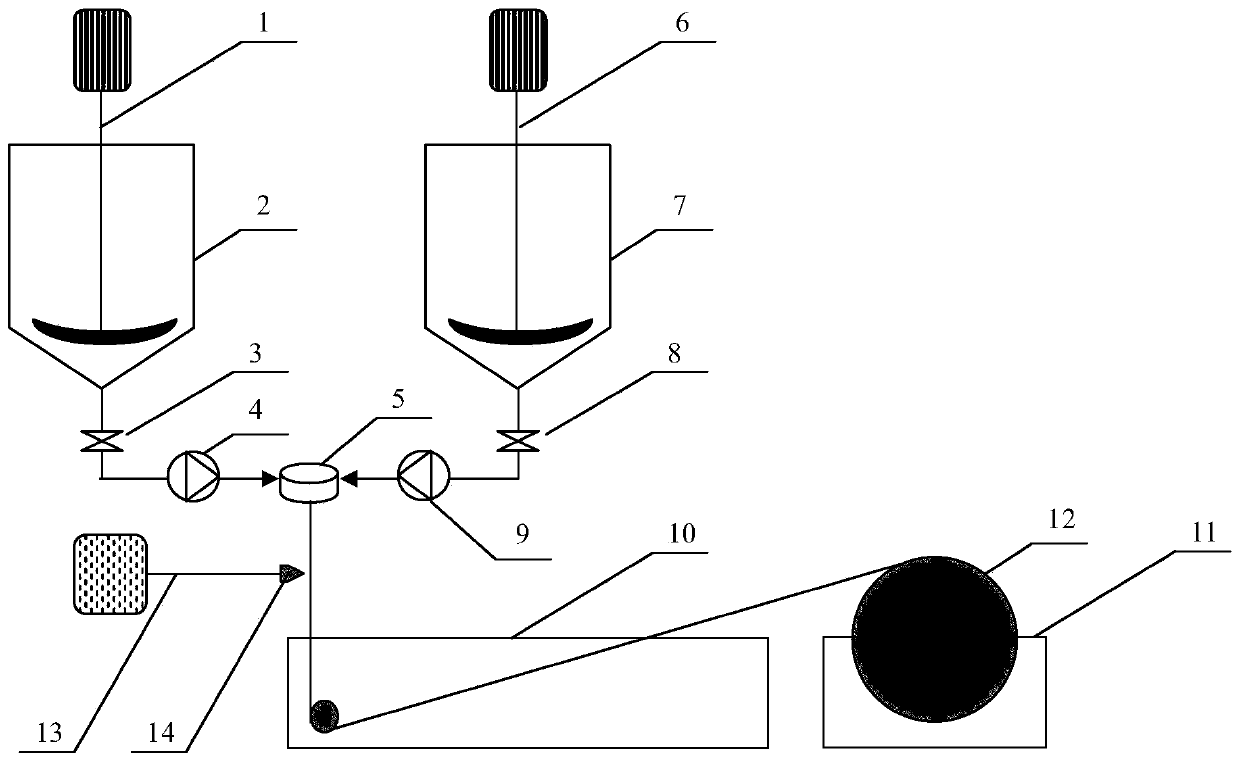

[0036] 1. Prepare polyethersulfone casting solution and let stand for defoaming;

[0037] 2. Combine hydroxyl carbon nanotubes, liquid crystal supramolecules, polyethersulfone, etc. with high temperature and high pressure sputtering solution;

[0038] 3. Set the sputter spinning conditions, including: the sputter pressure is 1 MPa, the sputter speed is 5m / s, the sputter spinning equipment is turned on, and the supramolecular yarn is spun by air spinning technology;

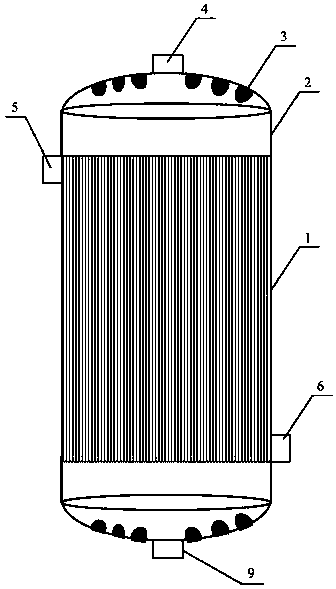

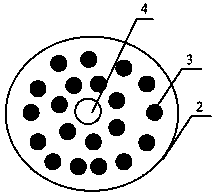

[0039] 4. Turn on the hollow fiber spinning machine, and under a certain temperature and pressure, make the casting solution pass through the spinneret, enter the coagulation bath with the supramolecular yarn at the same time, and undergo phase transformation to form a film. The supramolecule wraps the polyethersulfone, and at the same time wraps the hydroxyl carbon nanotube and embed...

Embodiment 2

[0041] Whole network supramolecular reinforcement reinforced liquid crystal supramolecular / polysulfone hollow fiber membrane:

[0042] 1. Prepare polysulfone casting solution, let it stand for defoaming;

[0043] 2. Combine hydroxyl carbon nanotubes, liquid crystal supramolecules, polysulfone, etc. with high temperature and high pressure sputtering solution;

[0044] 3. Set the sputter spinning conditions, including: the sputter pressure is 5MPa, the sputter speed is 100 m / s, the sputter spinning equipment is turned on, and the supramolecular yarn is spun by air spinning technology;

[0045] 4. Turn on the hollow fiber spinning machine, and under a certain temperature and pressure, make the casting solution pass through the spinneret, enter the coagulation bath with the supramolecular yarn at the same time, and undergo phase transformation to form a film. The supramolecule wraps the polysulfone, and at the same time wraps the hydroxyl carbon nanotube and embeds it in the fibe...

Embodiment 3

[0047] Multi-head supramolecular reinforcement reinforced liquid crystal supramolecular / polysulfone hollow fiber membrane:

[0048] 1. Prepare polysulfone casting solution, let it stand for defoaming;

[0049] 2. Combine hydroxyl carbon nanotubes, liquid crystal supramolecules, polysulfone, etc. with high temperature and high pressure sputtering solution;

[0050] 3. Set the sputter spinning conditions, including: the sputter pressure is 20MPa, the sputter speed is 50 m / s, the sputter spinning equipment is turned on, and the supramolecular yarn is spun by air spinning technology;

[0051] 4. Turn on the hollow fiber spinning machine, and under a certain temperature and pressure, make the casting solution pass through the spinneret, enter the coagulation bath with the supramolecular yarn at the same time, and undergo phase transformation to form a film. The supramolecule wraps the polysulfone, and at the same time wraps the hydroxyl carbon nanotube and embeds it in the fiber t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com