Preparation method of polyvinylidene fluoride film for super-weather-proof photovoltaic module

A polyvinylidene fluoride, photovoltaic module technology, used in applications, flat products, household appliances, etc., can solve the problems of low yield, poor thickness consistency, high cost, and achieve the effect of uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

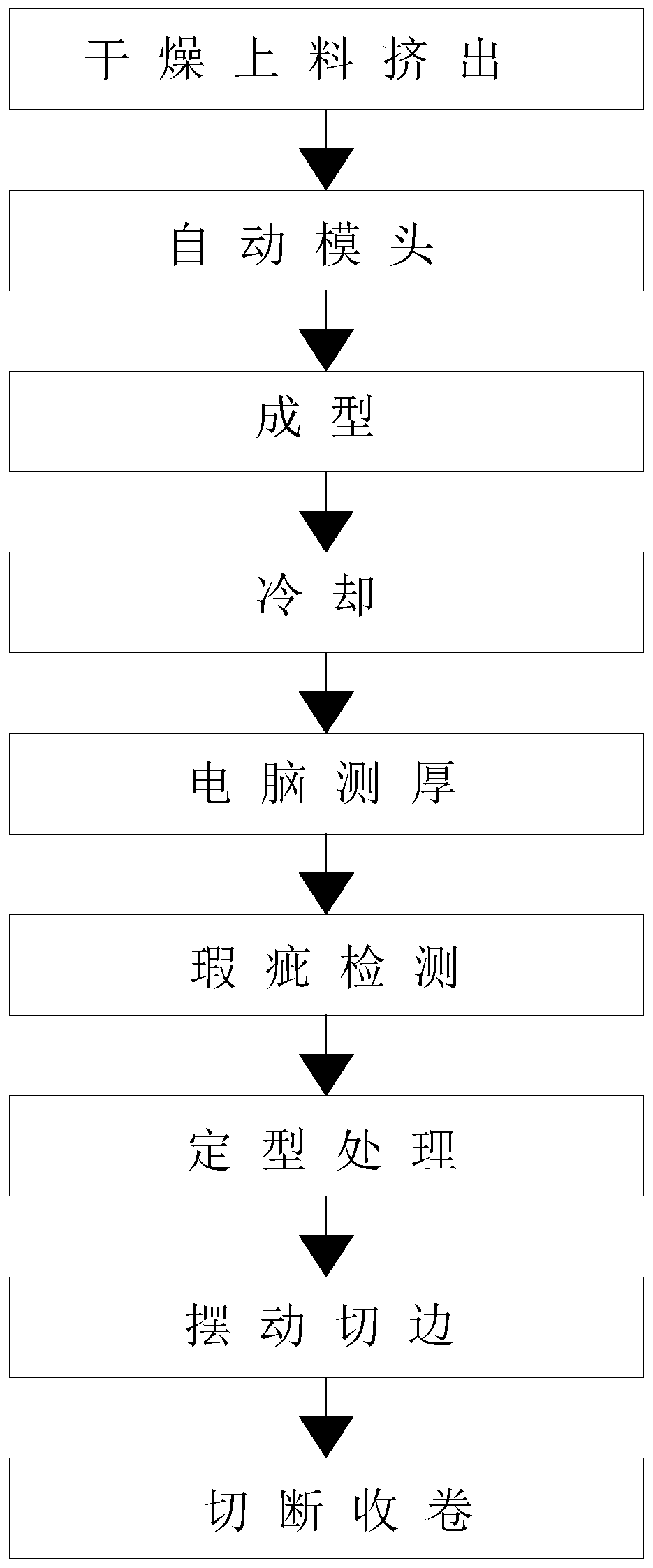

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] see as figure 1 As shown, the preparation method of the polyvinylidene fluoride film for the super weather-resistant photovoltaic module comprises the following steps;

[0029] 1. Load the granulated raw materials to the drying hopper device, and the lining of the hopper is made of stainless steel;

[0030] 2. Enter the extruder through the feed port. The extruder adopts a special screw structure. The plasticization of PVDF material and extrusion molding film have less crystal point; the frequency of the extruder is 20-22HZ, and the line speed is 32±3m / min, the current of the extruder is within 80A.

[0031] 3. The mold makes a special flow channel design and pressure distribution for PVDF material, and automatically adjusts the discharge gap of the mold according to the feedback of the computer to achieve uniform film thickness and ensure the quality of PVDF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com