Combinatorial material with metal luster, ultrahigh toughness and excellent weather resistance and preparation method of combinatorial material

A technology of metallic luster and combined materials, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of insignificant improvement of weld lines, and achieve good impact performance, good bonding force, and good transparency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

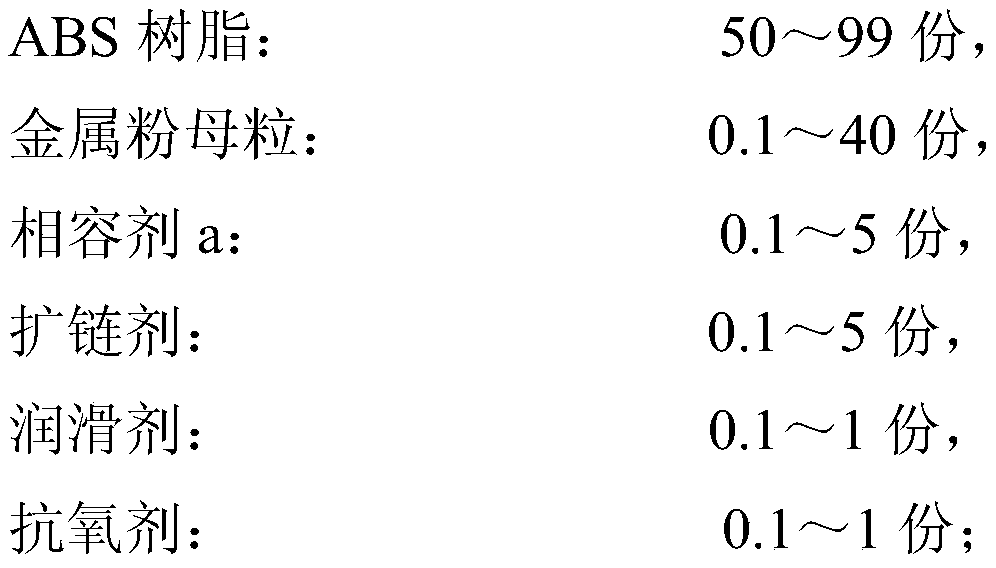

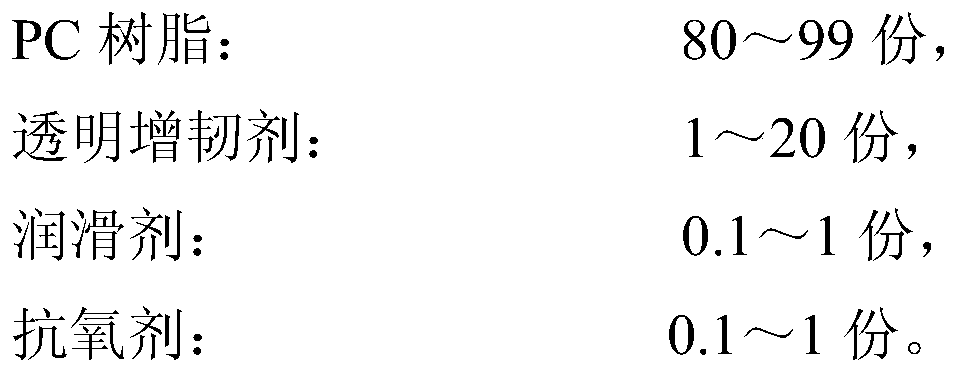

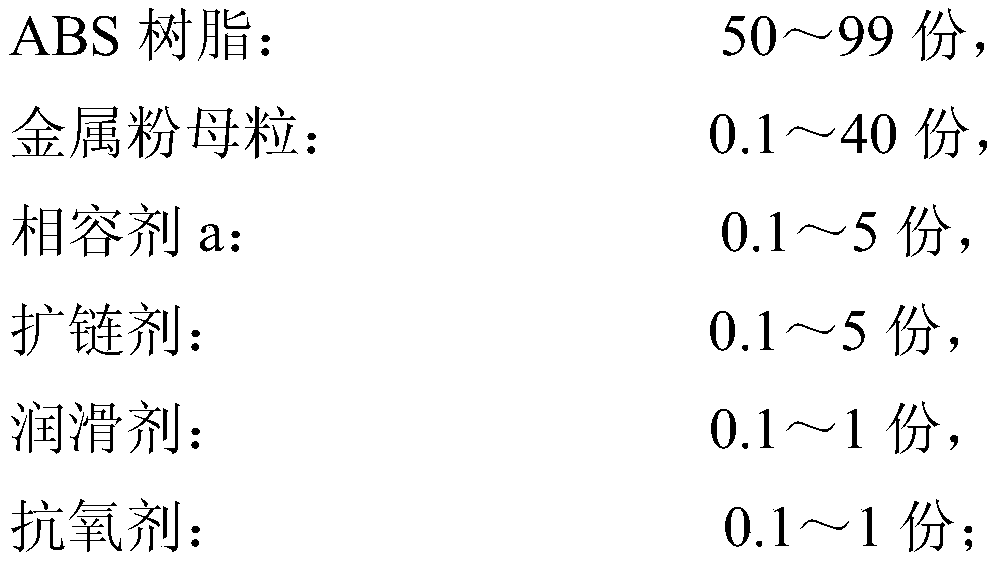

Method used

Image

Examples

Embodiment 4-10

[0087] The preparation method of the metallic luster ABS material of embodiment 4-10:

[0088] (a) prepare materials according to the described components and percentage by weight;

[0089] (b) Place each component of the prepared material in a high-speed mixer, and mix for 5 to 20 minutes to obtain a mixed material;

[0090] (c) adding the mixture into a twin-screw extruder, extruding and preparing a metallic luster ABS sheet, wherein the barrel speed of the twin-screw extruder is 15-35 rpm, and the barrel temperature is 200-240°C.

[0091] (d) Making the obtained metallic luster ABS sheet into a component after blister molding. Blister forming temperature is 220-270°C, mold temperature is 60-100°C.

[0092] Evaluation of the implementation effect:

[0093] With the metallic luster ABS material sample that above-mentioned comparative example 1-6 and embodiment 1-10 obtain, product performance test method is as follows:

[0094] Melt index: according to ISO 1133, tested un...

Embodiment 14

[0127] According to Table 7, put the plastic parts of metallic luster ABS into the mold, and then insert them with PC alloy materials to make metallic luster composite material parts through insert injection molding. The bottom layer is metallic luster ABS material, and the surface layer is PC alloy material.

[0128] Table 7 Metallic parts

[0129]

[0130] Evaluation of the implementation effect:

[0131] Metal effect and weld line state: evaluated visually; the metal effect is divided into 10 grades, the higher the grade, the better the metal effect; the weld line state is divided into 10 grades, the higher the grade, the less obvious the weld line.

[0132] Falling Ball Impact: According to PV3905.

[0133] From Table 7, it can be seen that the combined material parts of Embodiment 9 and Embodiment 11 have the best metal effect, weld line and flow mark state, and ball impact performance. If the addition amount of SX-006 is too high, it will affect the transparency, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com