A kind of silicone weather-resistant adhesive with high displacement capacity and preparation method thereof

A silicone weather-resistant adhesive and capability technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of insufficient displacement capacity, insufficient adhesion, and debonding of sealants, and achieve excellent expansion and contraction. The effect of recovery, excellent weathering resistance, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

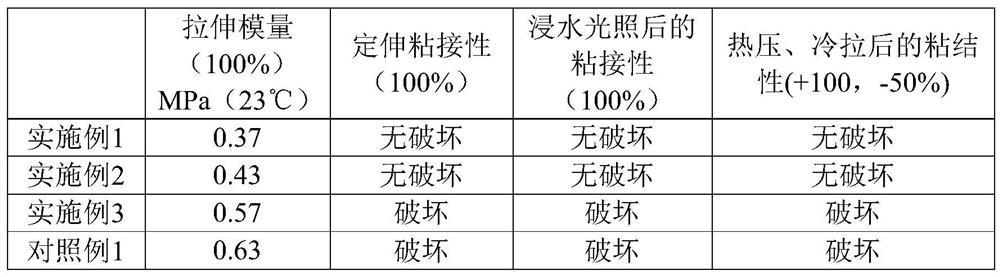

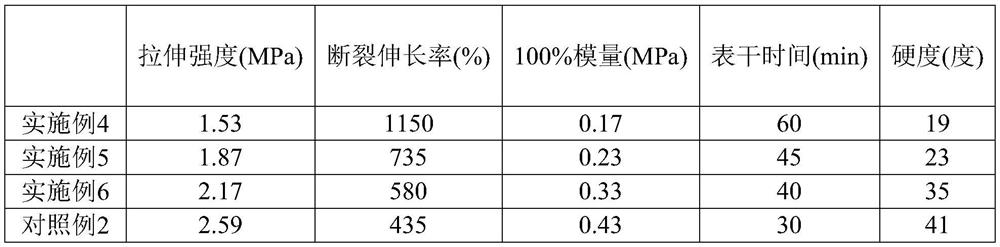

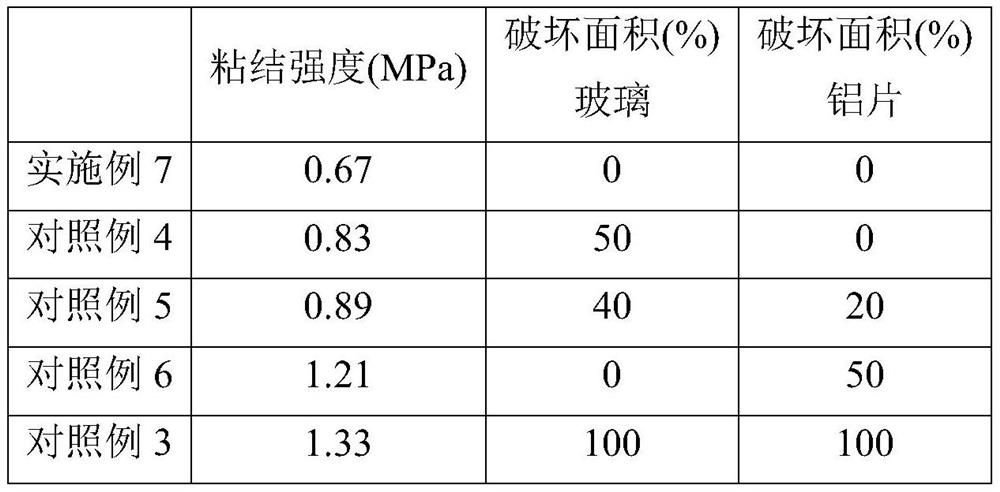

Embodiment 1

[0034] A preparation method of silicone weather-resistant adhesive with high displacement capacity, comprising the following steps:

[0035] 1) Put 100 parts of hydroxyl-terminated polydimethylsiloxane and 100 parts of nano-calcium carbonate into a kneader, wherein the hydroxyl-terminated polydimethylsiloxane has a viscosity of 50000cP at 25°C, and the particles of nano-calcium carbonate The diameter is 30-80nm, heated to 100-120°C and kneaded for 2-3 hours under vacuum airtight conditions to obtain the base rubber;

[0036] 2) Vacuumize the cooled base compound for 10 minutes;

[0037] 3) Add 6 parts of chain extender methylvinyl diisopropenyloxysilane and 6 parts of crosslinking agent phenyl tributylketoxime silane to the above-mentioned base material, and mix for 20 minutes under vacuum;

[0038] 4) Add 0.1 part of chelated tin catalyst and 1 part of silane coupling agent (MeO) 3 SiC 3 h 6 NHC 3 h 6 Si(MeO) 3 , mixed for 30 minutes, and vacuum removed the air bubbles...

Embodiment 2

[0040] A preparation method of a high-displacement silicone weather-resistant adhesive is basically the same as in Example 1, except that the chain extender methylvinyldiisopropenyloxysilane is added in 4 parts.

Embodiment 3

[0042] A method for preparing a high-displacement capacity storage-stable silicone weather-resistant adhesive is basically the same as in Example 1, except that the number of chain extender methylvinyldiisopropenyloxysilane added is 2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com