Anti-ultraviolet woven fabric

A technology of anti-ultraviolet, woven fabrics, applied in the directions of plant fibers, textiles and papermaking, fiber types, etc., can solve the problems of limited adhesion, large color difference of textiles, changing color of textiles, etc., achieving good durability, small color difference changes, The effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

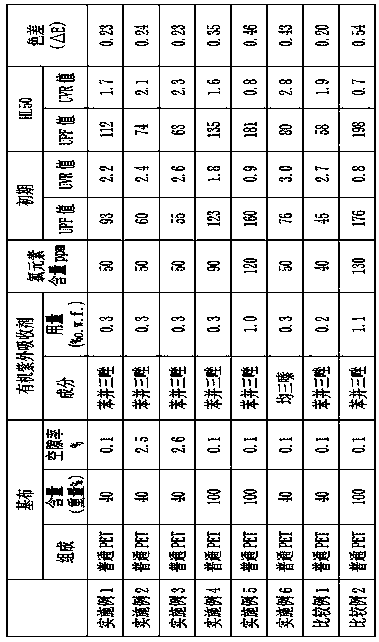

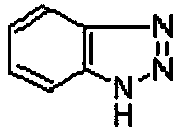

[0041] Select the polyester-cotton woven fabric that common PET content is 40% by weight, porosity 0.1%, put it in the dyeing machine, carry out in-bath processing in the finishing liquid that contains 0.3%o.w.f. benzotriazole ultraviolet absorber, The bath ratio is 1:20, and the product is obtained by incubating at 130°C for 30 minutes. The performance parameters of the obtained textiles are shown in Table 1.

Embodiment 2

[0043] The polyester-cotton woven fabric with a porosity of 0.1% is replaced with a polyester-cotton woven fabric with a porosity of 2.5%, and the rest are the same as in Example 1 to obtain the product. The performance parameters of the obtained textiles are shown in Table 1.

Embodiment 3

[0045] The polyester-cotton woven fabric with a porosity of 0.1% is replaced with a polyester-cotton woven fabric with a porosity of 2.6%, and the rest are the same as in Example 1 to obtain the product. The performance parameters of the obtained textiles are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com