Solid wood door structure and processing technique thereof

A processing technology, a technology for solid wood doors, applied in wood processing appliances, door leaves, windows/doors, etc., can solve problems such as the door body is prone to delamination, it is difficult to ensure the alignment of various wood strips, and the tactile feel and structural strength of solid wood doors are affected. , to achieve the effect of improving service life, improving impact resistance and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

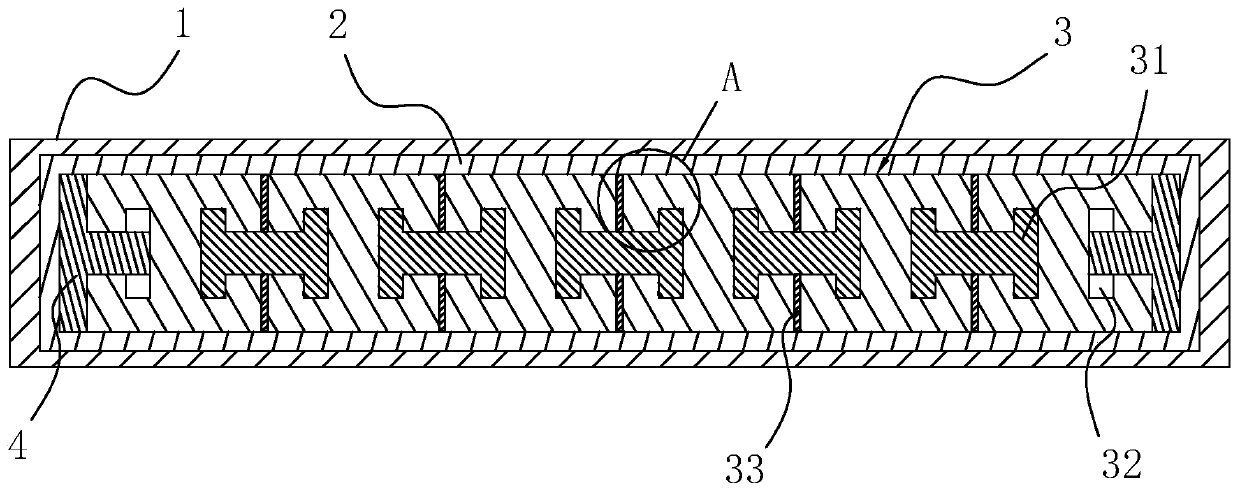

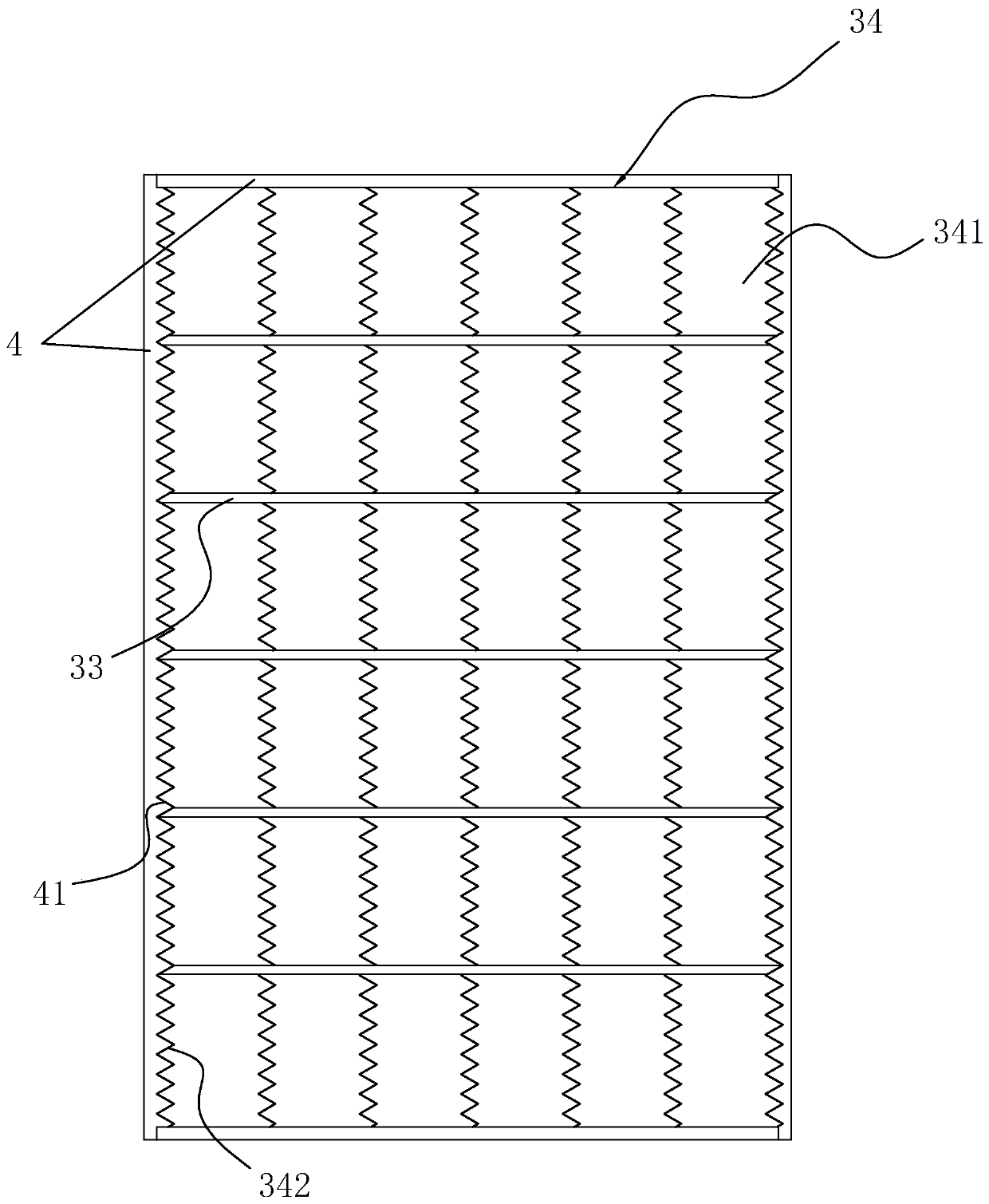

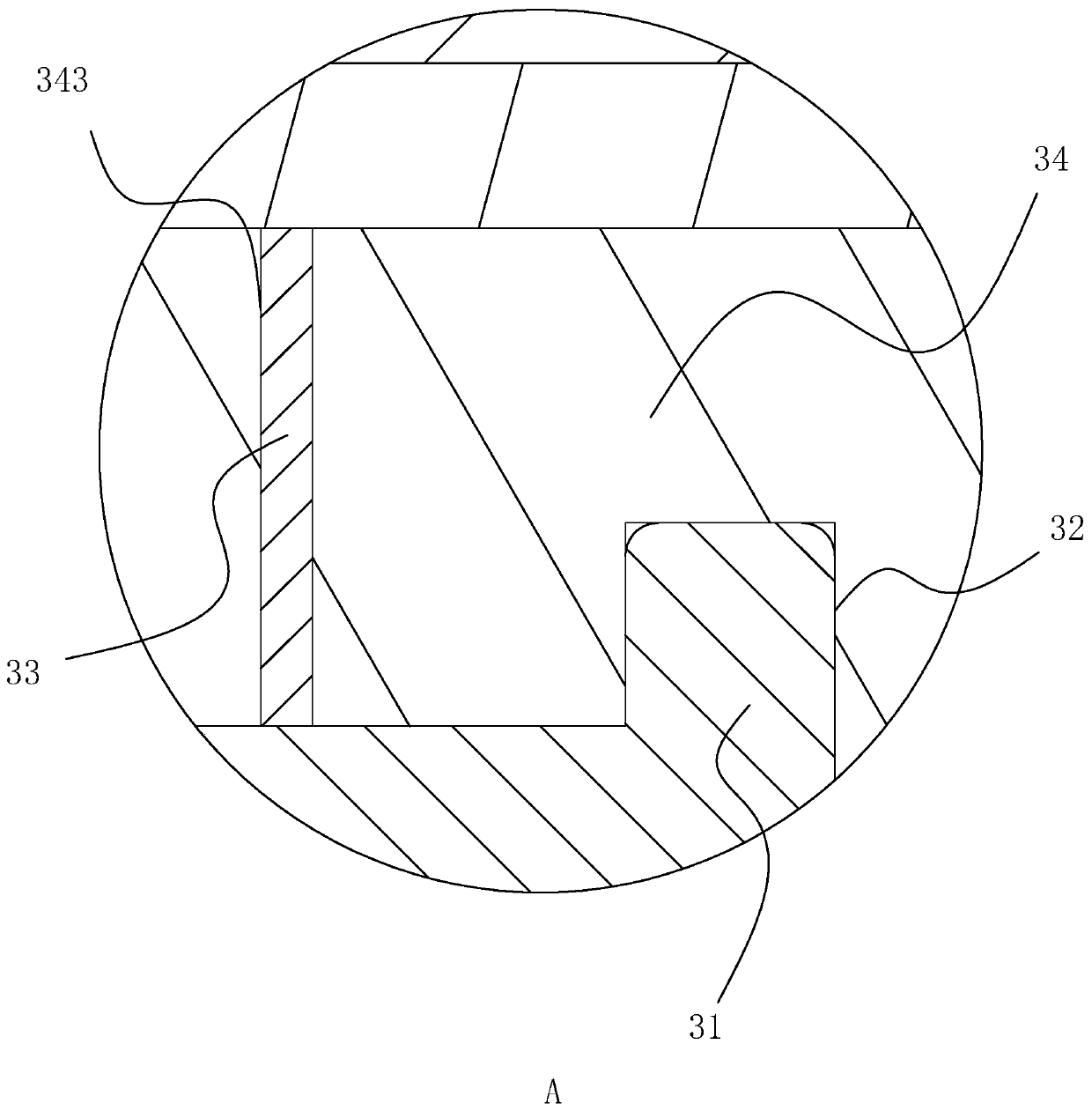

[0046] A solid wood door structure combined with figure 1 and figure 2As shown, including door body 3, four edge strips 4 that are respectively arranged on each side of door body 3, cover the diatom mud layer 2 of door body 3 and each edge strip 4, and cover the diatom mud layer The paint layer 1 on the 2; wherein, the door body 3 is composed of a plurality of wooden boards 34 arranged along the length direction of the door body 3, and a plurality of wooden boards 34 which are respectively arranged between the two adjacently arranged wooden boards 34 and are made of 440C steel. The connecting bar 31 and a plurality of cork boards 33 made of resin-based wood-ceramic composite material and used to fill the gap between the two adjacent boards 34 are assembled and formed.

[0047] combine figure 1 and image 3 As shown, the upper and lower sides of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com