Vertical graphene interconnection structure-based on-chip spiral inductor

A technology of spiral inductors and interconnection structures, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as poor thermal conductivity and electrical defects, and achieve the effects of reducing area, improving performance, and enhancing the overall inductance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

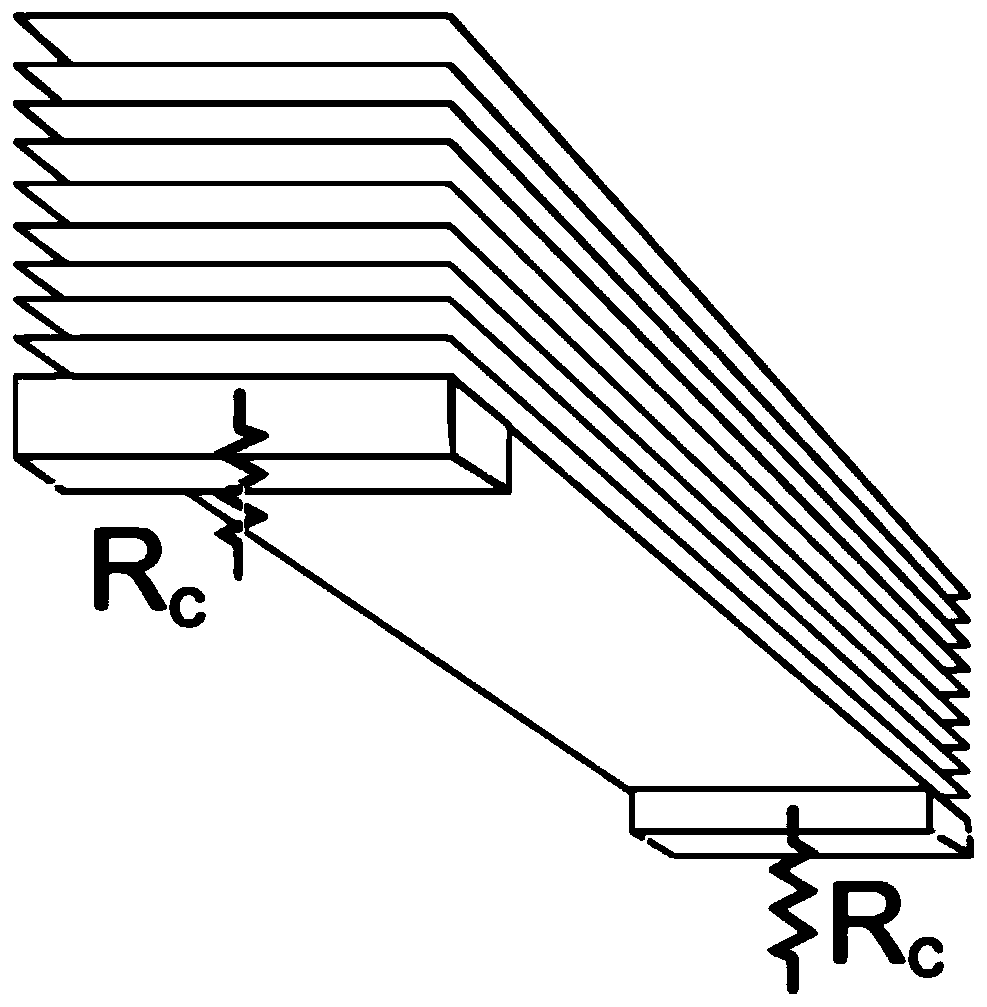

[0030] figure 1 It is a schematic diagram of multilayer horizontal graphene interconnection structure, which includes contact resistance Rc and multiple horizontal graphene layers. Due to the different manufacturing processes of materials, the value of contact resistance has a certain range of variation. from figure 1 It can be seen that this horizontal graphene interconnection can provide better reliability and stability than the traditional copper interconnection, but due to the low thermal conductivity in the vertical direction, there are certain problems in its heat dissipation.

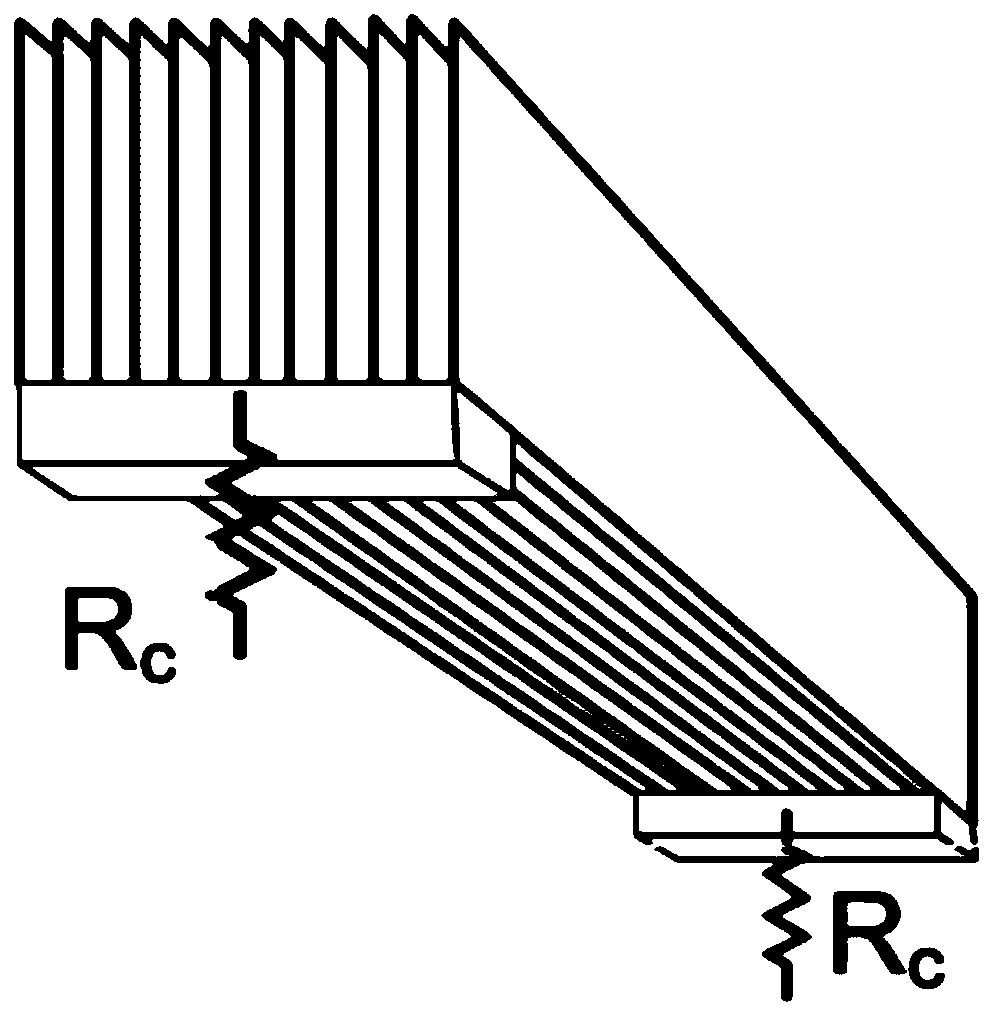

[0031] figure 2 Schematic diagram of a multilayer vertical graphene interconnect structure, including contact resistance and multiple vertical graphene layers. from figure 2 It can be seen that this vertical graphene interconnection structure will greatly increase the rate of heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com