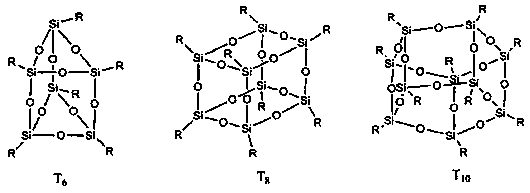

Formula and preparation method of POSS-based regenerative medical material

A technology for medical materials and formulations, applied in medical science, prostheses, etc., can solve the problems of low strength and few reactive groups, achieve high biological activity, and achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

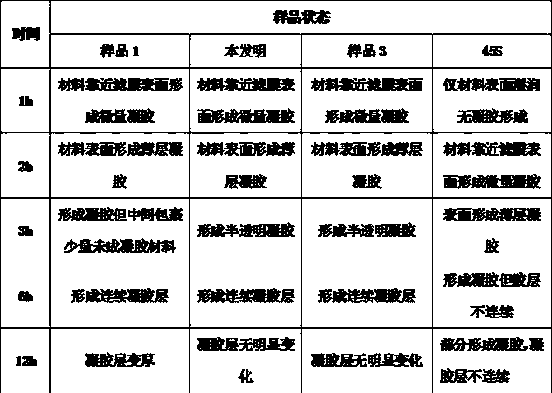

Examples

Embodiment 1

[0023] A formulation of POSS-based regenerative medicine material, comprising the following formulations in parts by weight:

[0024] Trialkoxysilane 80 parts

[0025] Methanol 72 parts

[0026] 22 parts of deionized water

[0027] Concentrated hydrochloric acid 3.2 parts

[0028] Phytic acid 5 parts

[0029] Contains 23 parts of calcium salts.

[0030] The preparation method of the formula of the POSS-based regenerative medicine material of the present embodiment comprises:

[0031] First, add 72 parts of methanol and 22 parts of deionized water into the reactor, then add 3.2 parts of catalyst concentrated hydrochloric acid and stir evenly, and measure the pH between 0.8-1.3;

[0032] Then, 80 parts of trialkoxysilane was added dropwise, and after the dropwise addition was completed, the mixture was stirred and reacted at 30-50°C for 6-8 hours to carry out the hydrolysis reaction;

[0033] Then, add 5 parts of phytic acid to promote polycondensation, and add 23 parts of...

Embodiment 2

[0043] A formulation of POSS-based regenerative medicine material, comprising the following formulations in parts by weight:

[0044] Trialkoxysilane 68 parts

[0045] Methanol 66 parts

[0046] 20 parts deionized water

[0047] 3 parts concentrated hydrochloric acid

[0048] Phytic acid 7 parts

[0049] Contains 25 parts of calcium salts.

[0050] The preparation method of the formula of the POSS-based regenerative medicine material of the present embodiment comprises:

[0051] First, add 66 parts of methanol and 20 parts of deionized water into the reactor, then add 3 parts of catalyst concentrated hydrochloric acid and stir evenly, and measure the pH between 0.8-1.3;

[0052] Then, 68 parts of trialkoxysilane was added dropwise, and after the dropwise addition was completed, the reaction was stirred at 30-50°C for 6-8 hours, and the hydrolysis reaction was carried out;

[0053] Then, add 7 parts of phytic acid to promote polycondensation, and add 25 parts of calcium-c...

Embodiment 3

[0062] A formulation of POSS-based regenerative medicine material, comprising the following formulations in parts by weight:

[0063] Trialkoxysilane 56 parts

[0064] Methanol 64 parts

[0065] 18 parts deionized water

[0066] 3 parts concentrated hydrochloric acid

[0067] Phytic acid 9 parts

[0068] Contains 28 parts of calcium salts.

[0069] The preparation method of the formula of the POSS-based regenerative medicine material of the present embodiment comprises:

[0070] First, add 64 parts of methanol and 18 parts of deionized water into the reactor, then add 3 parts of catalyst concentrated hydrochloric acid and stir evenly, and measure the pH between 0.8-1.3;

[0071] Then, 56 parts of trialkoxysilane was added dropwise, and after the dropwise addition was completed, the mixture was stirred and reacted at 30-50°C for 6-8 hours to carry out the hydrolysis reaction;

[0072] Then, add 9 parts of phytic acid to promote polycondensation, and add 28 parts of calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com