Oxygen vacancy containing phenol hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and phenol technology, applied in the field of catalysis, can solve problems such as complex preparation process and metal electronic structure not widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of ZIF-67

[0034] First prepare 50 mL of 0.8 mol / L methanol solution of 2-methylimidazole and 50 mL of 0.1 mol / L methanol solution of cobalt nitrate hexahydrate. Prepare 50 mL of 20 g / L polyvinylpyrrolidone methanol solution, stir for 10 min, put 2-methylimidazole solution in, continue stirring for 10 min, add Co(NO 3 ) 2 ·6H 2 O methanol solution, mixed and stirred for 10 h, then stopped stirring, and left the mixture at room temperature for 1 h. After standing, the product was separated by centrifugation, washed 3 times with methanol, and finally washed at 80 o C dried in an oven for 8 h, and the sample was designated as ZIF-67.

[0035] (2) Preparation of CN materials

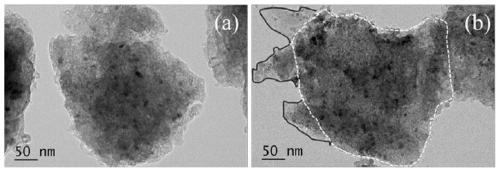

[0036]Take 1 g of prepared ZIF-67 in a tube furnace, the calcination atmosphere is argon, and the calcination temperature is 600 o C, the roasting time is 5 h. The temperature is raised from room temperature to the target temperature at a rate of 1 o C / min. The calcined sampl...

Embodiment 2

[0044] (1) Preparation of ZIF-67

[0045] First, prepare 100 mL of 1.2 mol / L methanol solution of 2-methylimidazole and 100 mL of 0.03 mol / L methanol solution of cobalt nitrate hexahydrate. Prepare 100 mL of 5 g / L polyvinylpyrrolidone methanol solution, put 2-methylimidazole solution into it while stirring, continue stirring for 30 min, add Co(NO 3 ) 2 ·6H 2 O methanol solution, mixed and stirred for 5 h, then stopped stirring, and left the mixture at room temperature for 5 h. After standing, the product was separated by centrifugation, washed 5 times with ethanol, and finally washed at 100 o C dried in an oven for 6 h, and the sample was designated as ZIF-67.

[0046] (2) Preparation of CN carrier

[0047] Get 1 g of prepared ZIF-67 in a tube furnace, the calcination atmosphere is argon, and the calcination temperature is 550 o C, the roasting time is 7 h. The temperature is raised from room temperature to the target temperature at a rate of 1 o C / min. The calcined s...

Embodiment 3

[0054] (1) Preparation of ZIF-67

[0055] First prepare 50 mL of 0.3 mol / L methanol solution of 2-methylimidazole and 50 mL of 0.15 mol / L methanol solution of cobalt nitrate hexahydrate. Prepare 50 mL of 30 g / L polyvinylpyrrolidone methanol solution, put 2-methylimidazole solution into it while stirring, continue stirring for 15 min, add Co(NO 3 ) 2 ·6H 2 O methanol solution, mixed and stirred for 15 h, then stopped stirring, and after standing for 3 h, the product was separated by centrifugation without washing, and finally at 60 o C dried in an oven for 24 h, and the sample was designated as ZIF-67.

[0056] (2) Preparation of CN carrier

[0057] Take 1 g of prepared ZIF-67 in a tube furnace, the roasting atmosphere is nitrogen, and the roasting temperature is 800 o C, the roasting time is 3 h. The temperature is raised from room temperature to the target temperature at a rate of 5 o C / min. The calcined samples were denoted as Co / CN. The prepared Co / CN samples were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com