A kind of oxygen-vacancy phenol hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and phenol technology, applied in the field of catalysis, can solve the problems such as the metal electronic structure is not widely used, the complex preparation process, etc., and achieve the effect of improving the hydrogenation performance of phenol and enhancing the electron transport ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

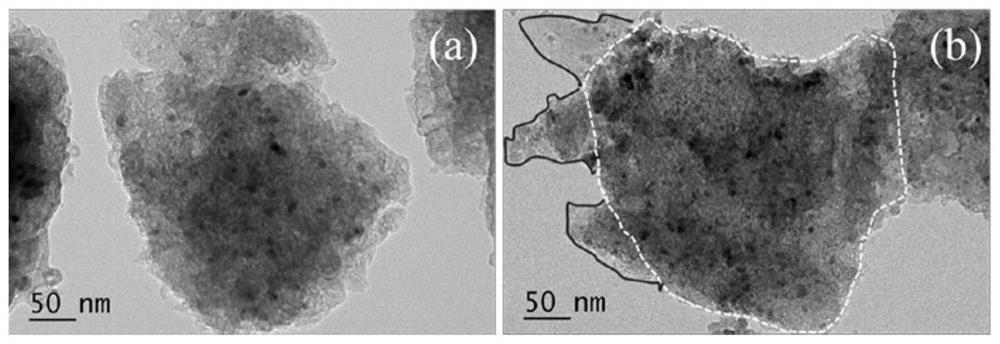

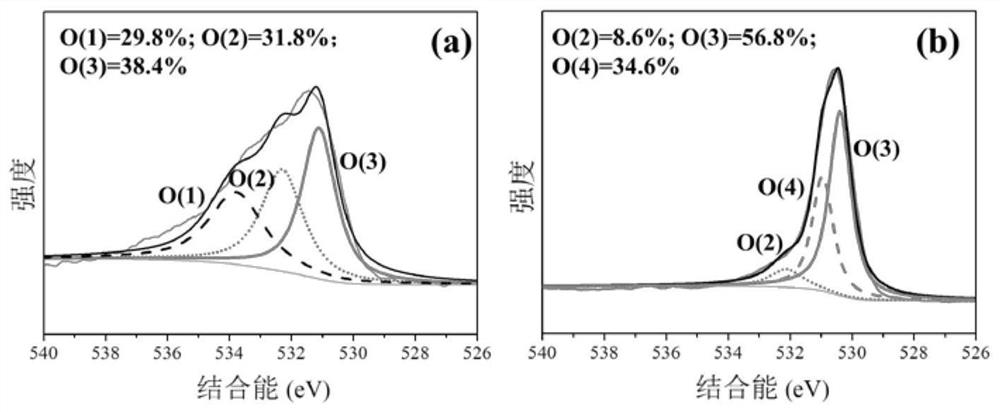

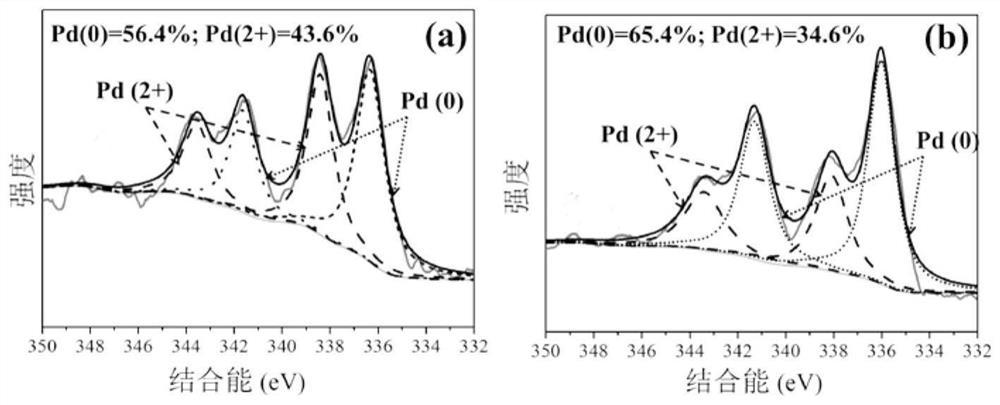

Image

Examples

Embodiment 1

[0033] (1) Preparation of ZIF-67

[0034] First prepare 50 mL of 0.8 mol / L methanol solution of 2-methylimidazole and 50 mL of 0.1 mol / L methanol solution of cobalt nitrate hexahydrate. Prepare 50 mL of 20 g / L polyvinylpyrrolidone methanol solution, stir for 10 min, put 2-methylimidazole solution in, continue stirring for 10 min, add Co(NO 3 ) 2 ·6H 2 O methanol solution, mixed and stirred for 10 h, then stopped stirring, and left the mixture at room temperature for 1 h. After standing, the product was separated by centrifugation, washed 3 times with methanol, and finally washed at 80 o C dried in an oven for 8 h, and the sample was designated as ZIF-67.

[0035] (2) Preparation of CN materials

[0036]Take 1 g of prepared ZIF-67 in a tube furnace, the calcination atmosphere is argon, and the calcination temperature is 600 o C, the roasting time is 5 h. The temperature is raised from room temperature to the target temperature at a rate of 1 o C / min. The calcined sampl...

Embodiment 2

[0044] (1) Preparation of ZIF-67

[0045] First, prepare 100 mL of 1.2 mol / L methanol solution of 2-methylimidazole and 100 mL of 0.03 mol / L methanol solution of cobalt nitrate hexahydrate. Prepare 100 mL of 5 g / L polyvinylpyrrolidone methanol solution, put 2-methylimidazole solution into it while stirring, continue stirring for 30 min, add Co(NO 3 ) 2 ·6H 2 O methanol solution, mixed and stirred for 5 h, then stopped stirring, and left the mixture at room temperature for 5 h. After standing, the product was separated by centrifugation, washed 5 times with ethanol, and finally washed at 100 o C dried in an oven for 6 h, and the sample was designated as ZIF-67.

[0046] (2) Preparation of CN carrier

[0047] Get 1 g of prepared ZIF-67 in a tube furnace, the calcination atmosphere is argon, and the calcination temperature is 550 o C, the roasting time is 7 h. The temperature is raised from room temperature to the target temperature at a rate of 1 o C / min. The calcined s...

Embodiment 3

[0054] (1) Preparation of ZIF-67

[0055] First prepare 50 mL of 0.3 mol / L methanol solution of 2-methylimidazole and 50 mL of 0.15 mol / L methanol solution of cobalt nitrate hexahydrate. Prepare 50 mL of 30 g / L polyvinylpyrrolidone methanol solution, put 2-methylimidazole solution into it while stirring, continue stirring for 15 min, add Co(NO 3 ) 2 ·6H 2 O methanol solution, after mixing and stirring for 15 h, stop stirring, and after standing for 3 h, the product was separated by centrifugation without washing, and finally at 60 o C dried in an oven for 24 h, and the sample was designated as ZIF-67.

[0056] (2) Preparation of CN carrier

[0057] Take 1 g of prepared ZIF-67 in a tube furnace, the roasting atmosphere is nitrogen, and the roasting temperature is 800 o C, the roasting time is 3 h. The temperature is raised from room temperature to the target temperature at a rate of 5 o C / min. The calcined samples were denoted as Co / CN. The prepared Co / CN samples were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com