Trace rare earth ion containing all silicon-1 molecular sieve based catalyst with microspheric MFI topological structure and spray shaping preparation method thereof

A technology of rare earth ions and molecular sieves, which is applied in the preparation of molecular sieve catalysts, physical/chemical process catalysts, and lactams, etc., to achieve obvious cost advantages, high total selectivity and total yield, and reduced energy consumption for product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The invention also discloses a method for preparing the catalyst by spraying, comprising the following steps:

[0058] a. Mix silicon source, rare earth ion source, organic template and water to obtain a colloidal mixture; wherein, SiO in the colloidal mixture 2 The molar ratio of organic templating agent and water is 1: (0.05-0.50): (5-100); in terms of silicon dioxide, the mass ratio of silicon source and rare earth ion is (10000-200000): 1; The above colloidal mixture is hydrothermally crystallized at 50-60°C for 0.5-3 days, then hydrothermally crystallized at 80-120°C for 0.5-3 days, and the obtained crystallized product is membrane filtered and washed until the pH value is 7.5-10 to obtain a molecular sieve slurry with a solid content of 25-35 wt%.

[0059] b. Mixing the molecular sieve slurry with a binder and beating to obtain a molecular sieve-binder mixed slurry with a solid content of 10-35 wt%.

[0060] c. Spray molding the molecular sieve-binder mixed slur...

Embodiment 1

[0082] With tetrapropyl ammonium hydroxide, 14.6gCe(NO 3 ) 4 ·7H 2 O and 440kg of water were mixed and stirred for 5 hours at room temperature to form a colloidal mixture with a pH value of 12.45, and the molar ratio of the mixture was SiO 2 :TPAOH:H 2 O=1:0.2:20, SiO 2 with Ce 3+ The mass ratio is 30300:1, the above mixture is moved into 2m 3 In a stainless steel reaction kettle, hydrothermal crystallization was performed at 50°C for 1 day, and then at 100°C for 2 days. water for washing, the amount of washing water is 7.0m 3 , the pH value of the washing water of the crystallized product reaches 9.1. Concentration of the slurry obtained after washing: 395 kg molecular sieve slurry with a solid content of 26.8% by weight.

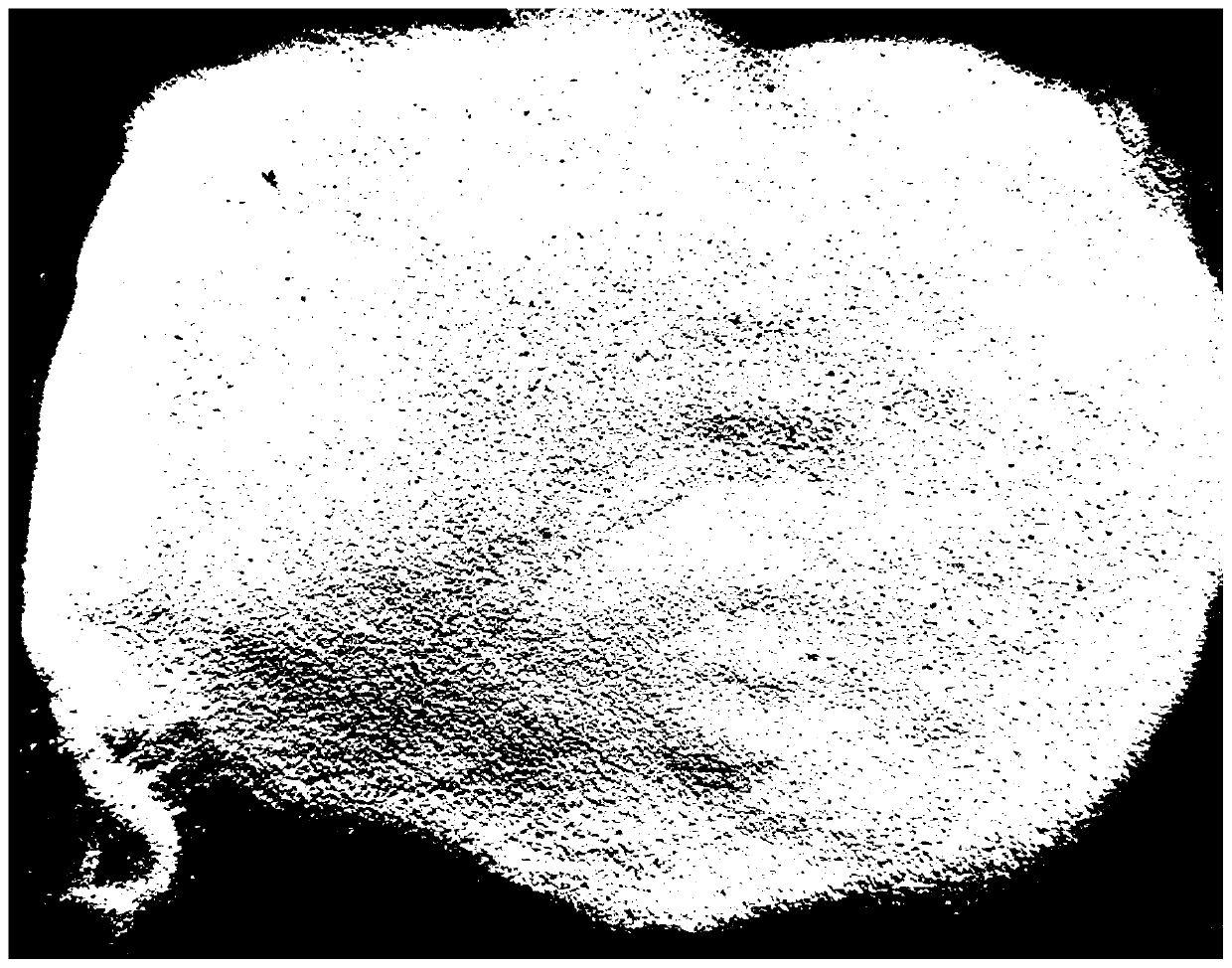

[0083] Take a small amount of the molecular sieve slurry and dry it at 120° C. for 20 hours to obtain the original powder of all-silicon-1 molecular sieve containing very small amount of rare earth ions. All-silicon-1 molecular sieve was calcined ...

Embodiment 2

[0091] With tetrapropylammonium hydroxide, 28gCe(NO 3 ) 3 ·6H 2 O and 440kg of water were mixed and stirred for 5 hours at room temperature to form a colloidal mixture with a pH value of 12.47, and the molar ratio of the mixture was SiO 2 :TPAOH:H 2 O=1:0.2:20, SiO 2 with Ce 3+ The mass ratio is 13500:1, the above mixture is moved into 2m 3 In a stainless steel reaction kettle, hydrothermal crystallization was performed at 50°C for 1.5 days, and then at 100°C for 1.5 days. The pH value of the crystallized product was 13.73. of water for washing, the amount of washing water is 6.7m 3 , the pH value of the washing water of the crystallized product reaches 9.0. Concentration of the slurry obtained after washing: 436 kg molecular sieve slurry with a solid content of 24.5% by weight.

[0092] Take a small amount of the molecular sieve slurry and dry it at 120° C. for 20 hours to obtain the original powder of all-silicon-1 molecular sieve containing very small amount of rare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

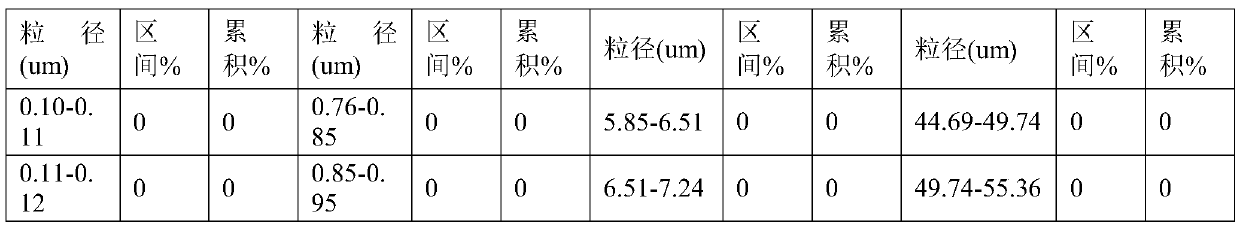

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com