Efficient electrochemical water treatment technology and device

A water treatment equipment, electrochemical technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of affecting the effect of wastewater treatment, limited service life of cathodes and anodes, and decreased efficiency. , to achieve the effect of saving time and effort in maintenance and cleaning, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

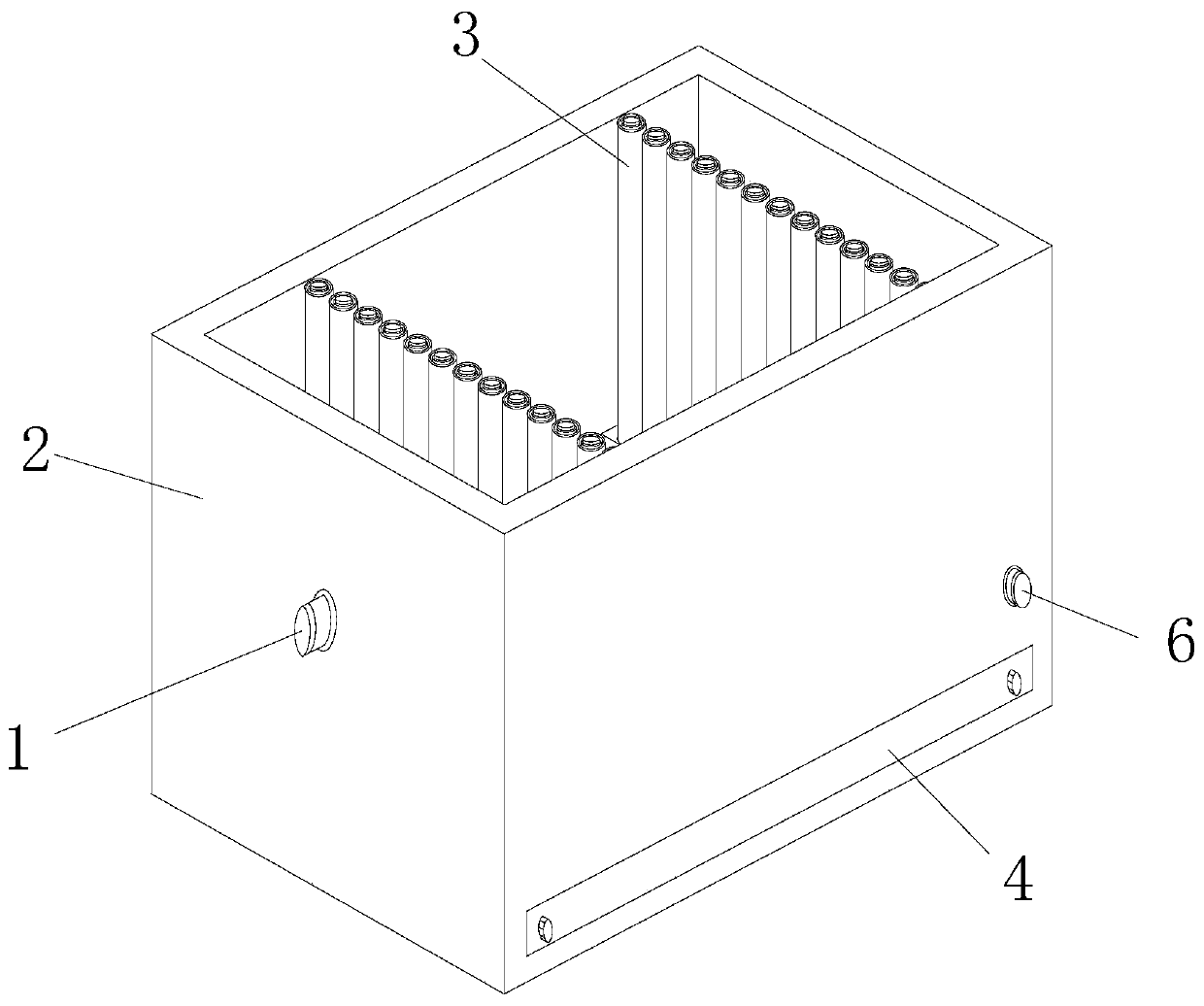

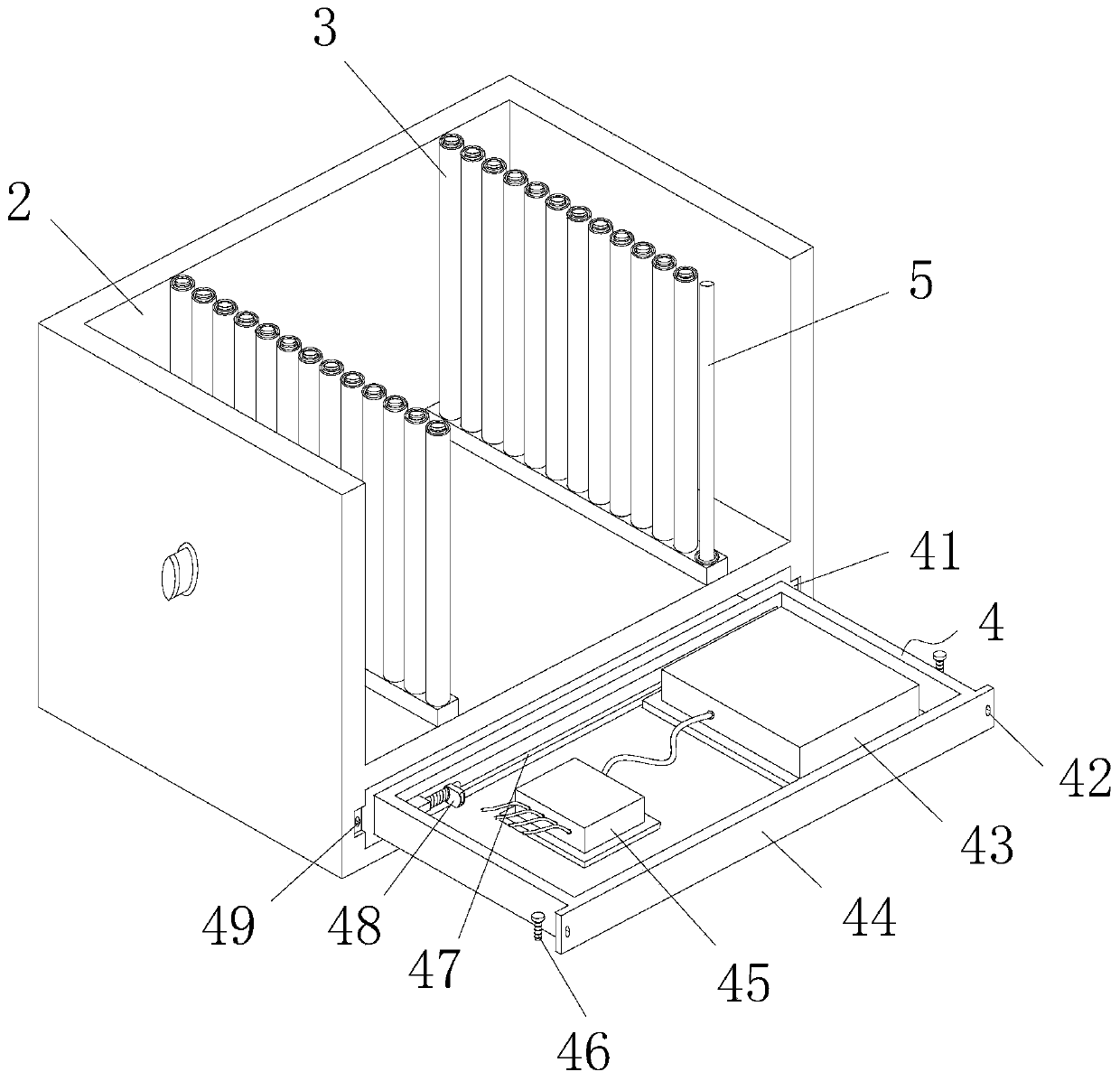

[0035] see Figure 1-6 , the present invention provides the following technical solutions: a high-efficiency electrochemical water treatment equipment, including an electrolytic cell 2, one side of the electrolytic cell 2 is provided with a water inlet 1, and the other side of the electrolytic cell 2 is ninety percent from the water inlet 1 A suction port 6 is provided at a ten-degree position, and electrode plates 3 are symmetrically arranged on the left and right sides of the electrolytic cell 2, and the electrolytic cell 2 and the electrode plate 3 are fixedly connected by a connecting mechanism 5. control mechanism4.

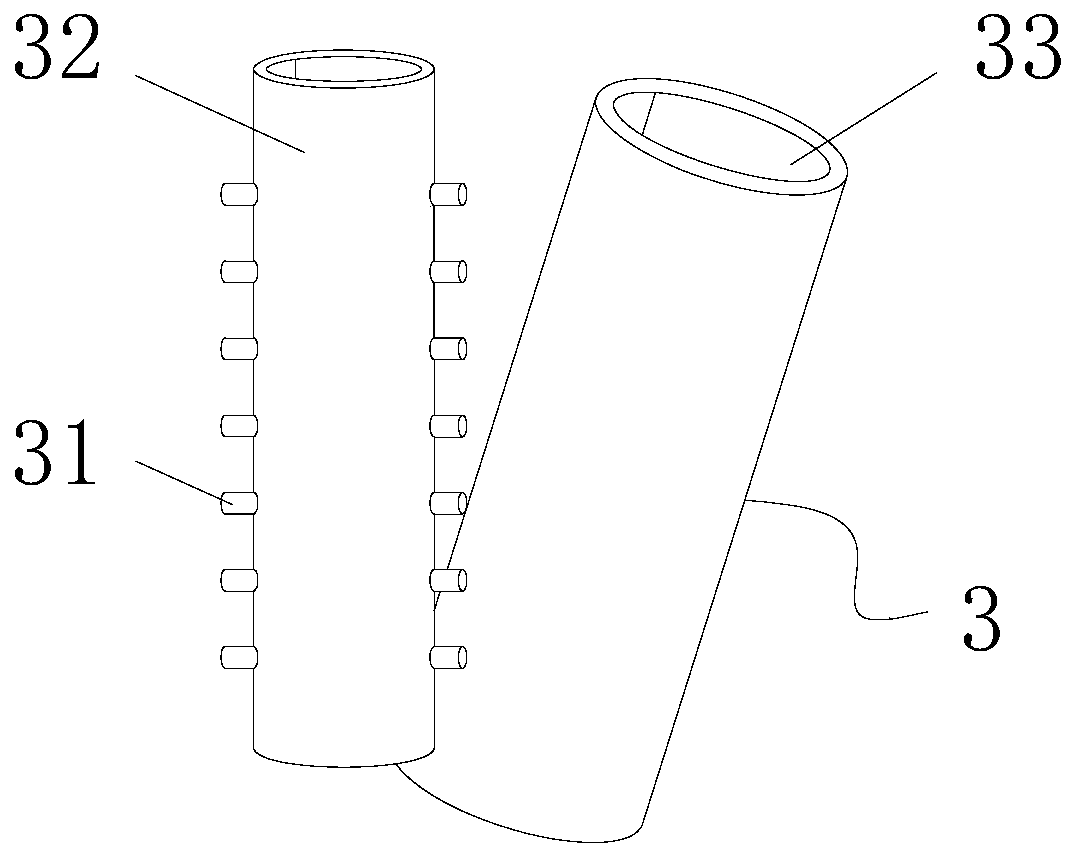

[0036] In order to realize the function of switching electrodes, in this embodiment, preferably, the electrode plate 3 includes a connector 31, an electrode plate inner ring 32 and an electrode plate outer ring 33, wherein the electrode plate inner ring 32 is provided with an electrode plate outer ring 33. The inner ring 32 of the electrode plate is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com