Flocculant preparation method

A manufacturing method and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of difficult storage of treatment agents, poor flocculation/degradation effect, etc., and achieve good flocculation effect, high turbidity removal rate, COD The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

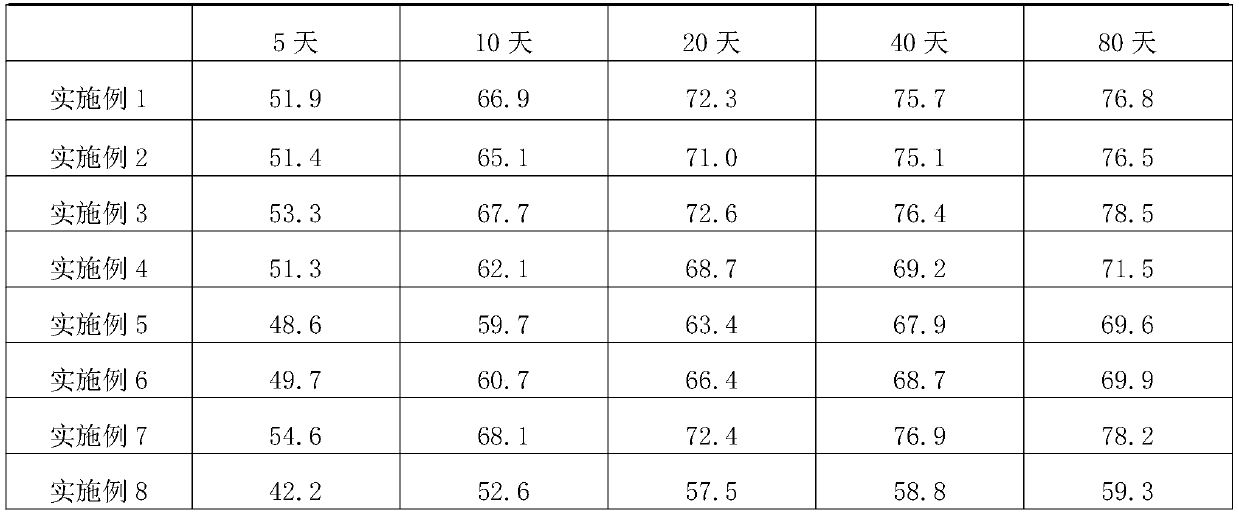

Examples

Embodiment 1

[0062] The flocculant is prepared by the following method:

[0063] A. The cellulose is washed with water;

[0064] B. Immerse the cellulose in a solution with a pH of 7.5, extract for 1 hour, and wash twice with water;

[0065] C. Freeze the cellulose processed in step B in a -5°C environment;

[0066] D. Take out the cellulose after the treatment in step C, place it in an acidic solution with a pH of 6.5, soak it, and when it returns to 5°C, take it out and wash it twice;

[0067] E. drying and crushing the cellulose after step D is cleaned into powder;

[0068] F. Put the powder in 0°C water;

[0069] G. Keep the temperature at 0°C, stir, and slowly add alkaline reagents to adjust the pH to 7.3 to obtain a uniform and transparent solution;

[0070] H. Add the above solution into a vacuum sealed kettle, add an oxidizing agent, and heat up to 40° C. for 2 hours;

[0071] I. The solution treated in step H is rotary evaporated and dried.

Embodiment 2

[0073] The flocculant is prepared by the following method:

[0074] A. The cellulose is washed with water;

[0075] B. Immerse the cellulose in a solution with a pH of 8, extract for 2 hours, and wash with water for 3 times;

[0076] C. Freeze the cellulose processed in step B in a -10°C environment;

[0077]D. Take out the cellulose after the treatment in step C, place it in an acidic solution with a pH of 6.8, soak it, and when it returns to 10°C, take it out and wash it with water for 3 times;

[0078] E. drying and crushing the cellulose after step D is cleaned into powder;

[0079] F. Place the powder in water at 4°C;

[0080] G. Keep the temperature at 4°C, stir, and slowly add alkaline reagents to adjust the pH to 7.5 to obtain a uniform and transparent solution;

[0081] H. Put the above solution into a vacuum-sealed kettle, add an oxidizing agent, and heat up to 50° C. for 3 hours;

[0082] I. The solution treated in step H is rotary evaporated and dried.

Embodiment 3

[0084] The flocculant is prepared by the following method:

[0085] A. The cellulose is washed with water;

[0086] B. Immerse the cellulose in a solution with a pH of 7.8, extract for 1.5 hours, and wash with water for 3 times;

[0087] C. Freeze the cellulose processed in step B in a -7°C environment;

[0088] D. Take out the cellulose after the treatment in step C, place it in an acidic solution with a pH of 6.7, soak it, and when it returns to 7°C, take it out and wash it twice;

[0089] E. drying and crushing the cellulose after step D is cleaned into powder;

[0090] F. Put the powder in 2°C water;

[0091] G. Keep the temperature at 2°C, stir, and slowly add alkaline reagents to adjust the pH to 7.4 to obtain a uniform and transparent solution;

[0092] H. Put the above solution into a vacuum sealed kettle, add an oxidizing agent, and heat up to 45°C for 2.5 hours;

[0093] I. The solution treated in step H is rotary evaporated and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com