Composite material based on high-strength lime/dextrin mortar and its preparation method

A composite material and high-strength technology, applied in the field of building materials, can solve the problems of low strength of lime-based inorganic/organic materials, and achieve the effects of easy implementation, accelerated condensation, and improved waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

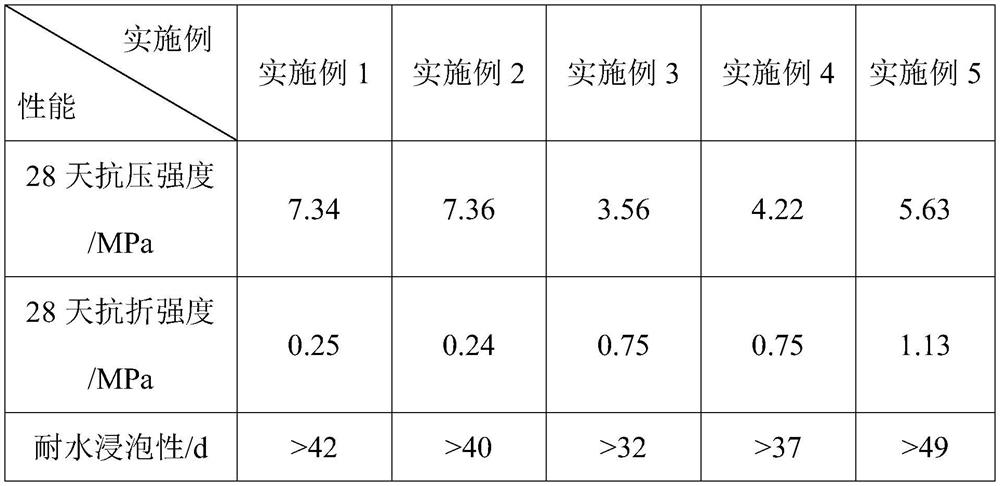

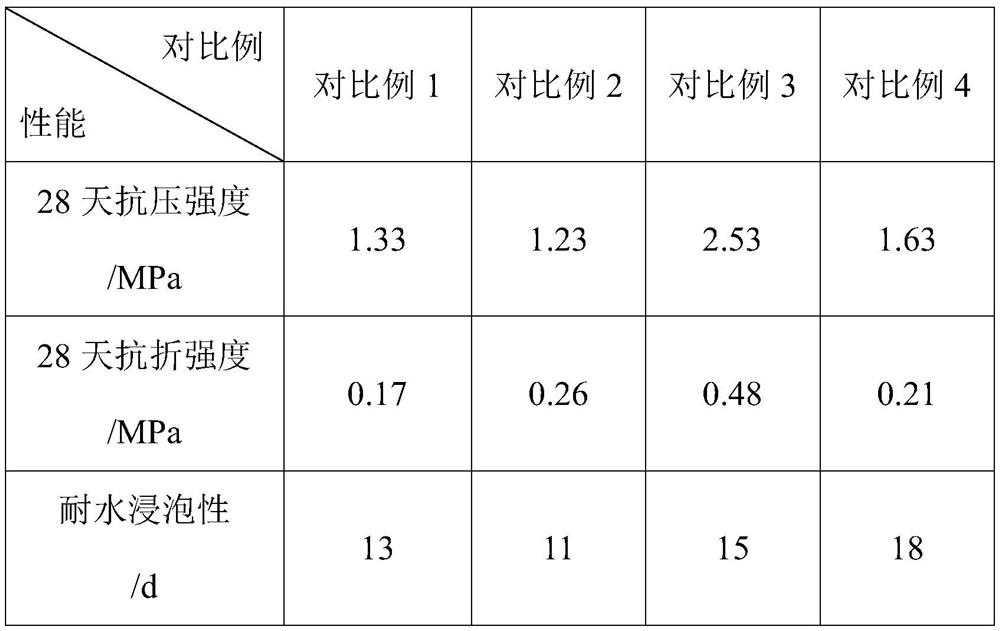

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing a composite material based on high-strength lime / dextrin mortar, specifically implemented according to the following steps:

[0040] Step 1. Preparation of dextrin slurry: Pour dextrin and water into the container at a ratio of 1:11.5, heat and stir until the temperature rises to 80°C, stop heating, and prepare a dextrin slurry with a mass concentration of 8%. ;

[0041] Step 2, take the following raw materials respectively by mass fraction:

[0042] Lime 21.4%, sand 64%, dextrin slurry 14%, sodium bicarbonate 0.6%;

[0043] Step 3. Pour lime into the filling material, and stir evenly to obtain mixture A, then add curing agent to form mixture B;

[0044] Step 4. Add a silane coupling agent to the dextrin slurry, pour them into the mixture B together, and stir evenly to form a composite material based on high-strength lime / dextrin mortar.

Embodiment 2

[0046] This embodiment provides a kind of preparation method based on the composite material of high-strength lime / dextrin mortar, and this method is the same as embodiment 1, and difference is:

[0047] In step 1, the mass ratio of dextrin to water is 1:5.3, and the mass concentration of the prepared dextrin slurry is 16%;

[0048] The raw materials weighed are lime 21.4%, sand 62%, dextrin slurry 16%, sodium carbonate 0.6%.

Embodiment 3

[0050] This embodiment provides a kind of preparation method based on the composite material of high-strength lime / dextrin mortar, and this method is the same as embodiment 1, and difference is:

[0051] In step 1, the mass ratio of dextrin to water is 1:7.3, and the mass concentration of the prepared dextrin slurry is 12%;

[0052] The raw materials weighed are 12% of lime, 80% of sand, 7.6% of dextrin slurry and 0.4% of sodium silicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com