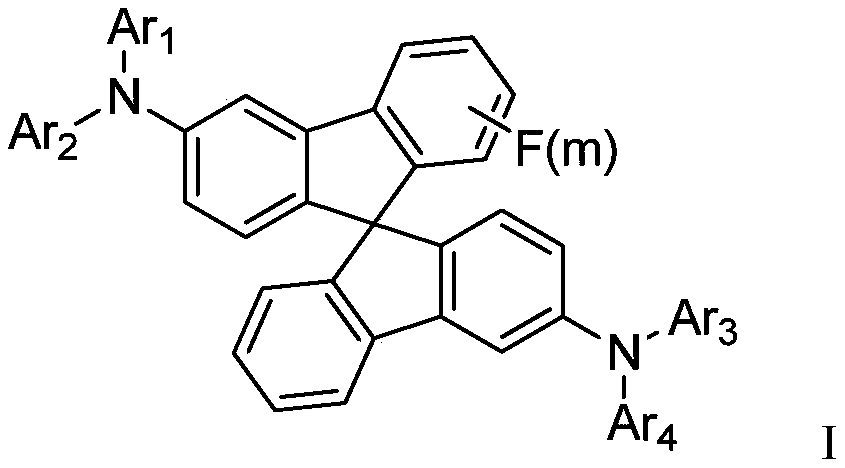

Fluorine-containing hole material of spirobifluorene structure and preparation method and application thereof

A spirobifluorene and hole technology, applied in the field of organic electroluminescence display, can solve the problems of low glass transition temperature, easy crystallization of materials, and destruction of film uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

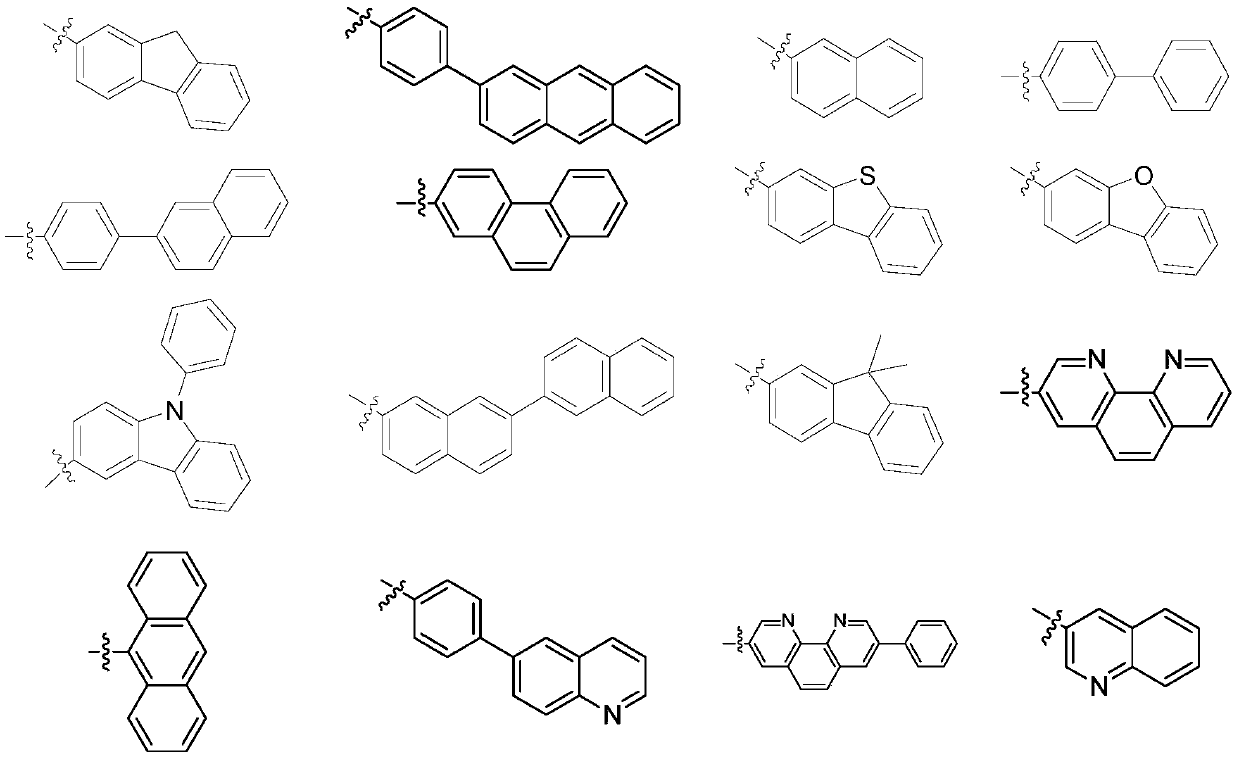

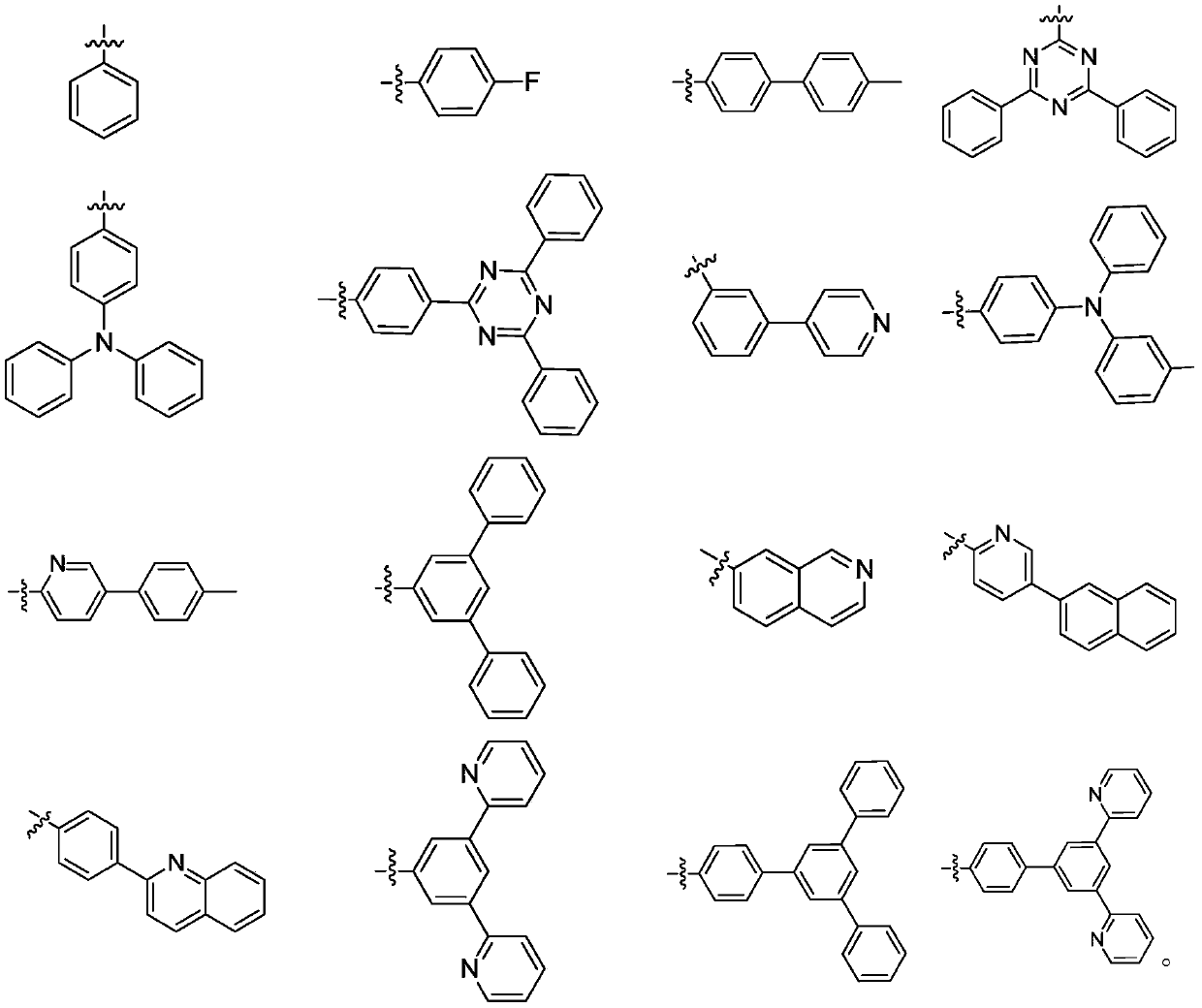

Method used

Image

Examples

Embodiment 1

[0071]

[0072] The synthetic route is as follows:

[0073]

[0074] Including the following specific steps:

[0075] Synthesis of compound B-23-2

[0076] 500 ml three-neck flask, equipped with magnetic stirring, after argon replacement, add 18.1 g (0.188 mol) of potassium tert-butoxide, N-([1,1'-biphenyl]-4-yl)-9H-fluoro-2- Amine 33.34g (purity 99%, 0.1mol) and toluene 100ml. After nitrogen replacement again, 1.6 ml of tri-tert-butylphosphine and 0.23 g of palladium acetate were successively added. After the addition was complete, the temperature was raised to 85°C. Start to drop a solution consisting of 49.22 g of fluorine-containing spirobifluorene dibromo-substituent compound (1-1) (purity 99%, 0.1 mol) and 100 ml of toluene, and control the temperature at 80-120°C. Cool down to 50°C, add 100m deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF, and rotary evaporate to obtain 64.67g white solid with a puri...

Embodiment 2

[0081]

[0082] The synthetic route is as follows:

[0083]

[0084] Including the following specific steps:

[0085] Synthesis of compound B-24-2

[0086] 500 ml three-necked flask equipped with magnetic stirring, after argon replacement, add 18.1 g (0.188 mol) of potassium tert-butoxide and 33.34 g (purity 99%, 0.1mol) and toluene 100ml. After nitrogen replacement again, 1.6 ml of tri-tert-butylphosphine and 0.23 g of palladium acetate were successively added. After the addition was complete, the temperature was raised to 85°C. Start to drop a solution consisting of 49.22g of fluorine-containing spirobifluorene dibromosubstituent compound (purity 99%, 0.1mol) and 100ml of toluene, and control the temperature at 80-120°C. Cool down to 50°C, add 100m deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF to obtain 65.52g of white solid with a purity of 99% and a yield of 88%.

[0087] Synthesis of compound I-24-2...

Embodiment 3

[0091]

[0092] The synthetic route is as follows:

[0093]

[0094] Including the following specific steps:

[0095] Synthesis of compound B-114-2

[0096] 500 ml three-necked flask, equipped with magnetic stirring, after argon replacement, add 18.1 g (0.188 mol) of potassium tert-butoxide and 35.14 g (purity 99%, 0.1mol) and toluene 100ml. After nitrogen replacement again, 1.6 ml of tri-tert-butylphosphine and 0.23 g of palladium acetate were successively added. After the addition was complete, the temperature was raised to 85°C. A solution consisting of 49.22 g of fluorine-containing spirobifluorene dibromosubstituents (purity 99%, 0.1 mol) and 100 ml of toluene was added dropwise, and the temperature was controlled at 80-120°C. Cool down to 50°C, add 100m deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF to obtain 69.02g of white solid with a purity of 99% and a yield of 90.5%.

[0097] Synthesis of comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com