Method for industrial continuous preparation of high-purity lactide

A lactide, high-purity technology, applied in the direction of organic chemistry, etc., can solve the problems of inability to achieve high-purity lactide, easy to decompose, not very successful, etc., and achieve the effects of being conducive to protection, less equipment investment, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

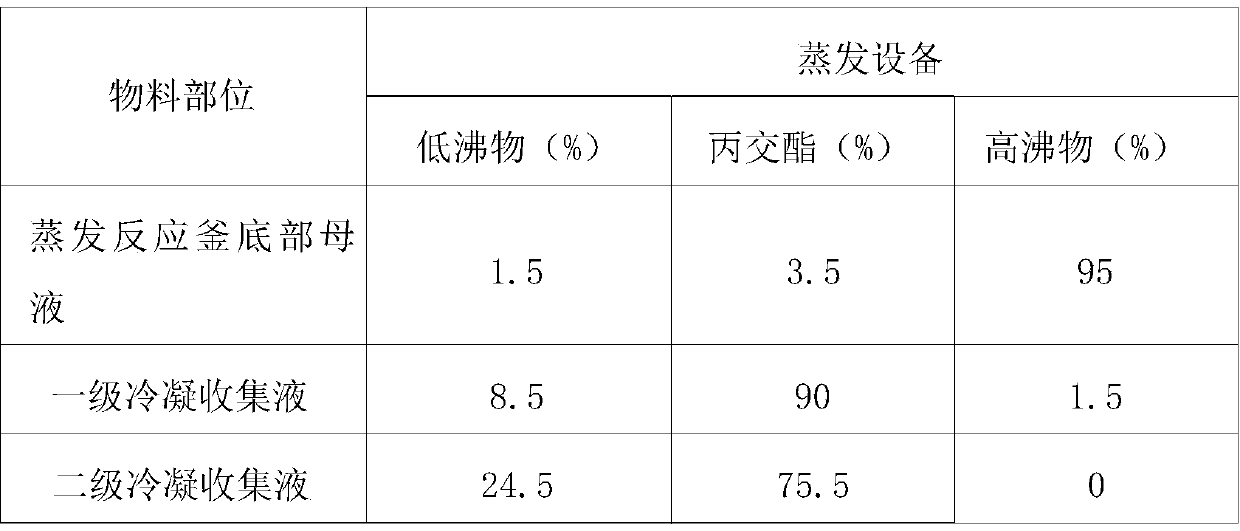

[0038] The crude lactide to be treated comprises the following components in mass percentage:

[0039] Lactide 92.9%

[0040] High boilers 3.6%

[0041] Low boilers 3.5%

[0042] The evaporation equipment is a common falling film evaporator:

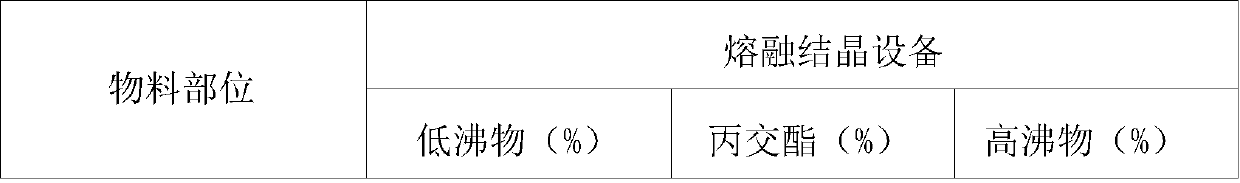

[0043] (1) Send the treated crude lactide into the falling film evaporator, and the material is continuously evaporated at a temperature of 160°C and a vacuum of 100Pa. The lactide evaporates rapidly under this condition, accompanied by internal The racemization, acid and water are distilled out together, and the crude lactide is collected through the first-stage condenser, and the temperature is controlled at 90°C. The crude lactide collected by the first-stage condenser is 90% of the total evaporated mass, and directly enters the melting crystallization device, melting and crystallization separation;

[0044] The temperature of the secondary condenser is 90°C, collect 10% of the total evaporation, and send it to the post-processing...

Embodiment 2

[0062] The crude lactide to be processed comprises the following components by weight percentage:

[0063] Lactide 93.8%

[0064] High boilers 3.4%

[0065] Low boilers 2.8%

[0066] The evaporation equipment is a common falling film evaporator:

[0067] (1) Send the treated crude lactide into the falling film evaporator, and the material is continuously evaporated at a temperature of 160°C and a vacuum of 100Pa. The lactide evaporates rapidly under this condition, accompanied by internal The racemization, acid and water are distilled out together, and the crude lactide is collected through the first-stage condenser, and the temperature is controlled at 90°C. The crude lactide collected by the first-stage condenser is 90% of the total evaporated mass, and directly enters the melting crystallization device, melting and crystallization separation;

[0068] The temperature of the secondary condenser is 90°C, collect 10% of the total evaporation, and send it to the post-proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com