Affine peptide and application thereof

An affinity peptide and affinity technology, applied in the field of purification and antibody separation, can solve the problem of unsatisfactory purification effect, and achieve the effect of cheap and easy quality control, easy quality control and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

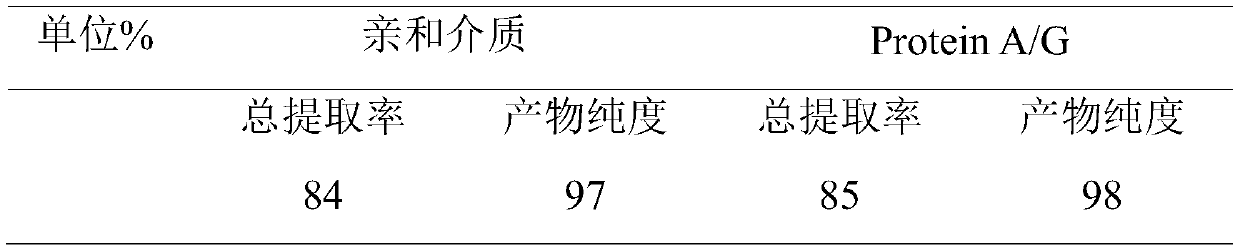

[0034] Example 3 Using the affinity medium obtained in Example 2 for the separation and purification of antibodies

[0035] 1) Prepare 10mmol / L Hepes buffer solution, pH7.0, NaCl content 0.15M. Set the flow rate to 1mL / min.

[0036] 2) Use the liquid prepared in 1) as the mobile phase, and run the AKTA protein purification system.

[0037] 3) Take 1 mL of the affinity medium prepared in Example 2 to fill the separation column, and use 1 mL of the Protein A / G prepacked column as a control.

[0038] 4) Load 1mL of antibody fermentation broth respectively. The antibody fermentation liquid can be the antibody fermentation liquid of hybridoma cells or the antibody fusion protein fermentation liquid of Escherichia coli.

[0039] 5) Prepare 0.1M HCl-Gly buffer at pH 2 as the eluent.

[0040] 6) Load 3 mL of the eluate, and collect the eluate.

[0041] 7) Determine the antibody content and purity in the eluent of the antibody fermentation broth, antibody-adsorbed peptide medium, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com