Novel kelp processing technology

A processing technology, kelp technology, applied in the field of new kelp processing technology, can solve the problems of difficult to meet the demand of kelp polysaccharides, easy to destroy kelp polysaccharides, waste of raw materials, etc., to avoid mutual inhibition and decomposition, reduce processing and pretreatment time, and reduce invalid The effect of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

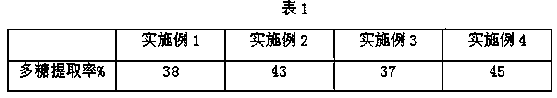

Examples

Embodiment 1

[0023] (1) After soaking and washing the kelp, add water 8 times the dry weight of the kelp and soak it naturally for 1 hour, squeeze the juice and pulverize it, collect the slag and the juice together, and obtain the kelp juice;

[0024] (2) Ultrasonic treatment of kelp juice, ultrasonic temperature 35°C, power 60W, time 25min;

[0025] (3) Add hydrochloric acid, citric acid and malic acid to the ultrasonically treated kelp juice to adjust the pH value to 4.0, adjust the temperature to 45°C, add 1% of the dry weight of kelp, and the activity is 3×10 4 U of pectinase, continue to stir for 1h; continue heating to raise the temperature to 55°C, add 1% of the dry weight of kelp, and the activity is 4×10 4 U of cellulase, stirring continuously for 1h; then adding sodium hydroxide to the juice to adjust the pH to 6, keeping the temperature, adding 0.5% of the dry weight of kelp, and the activity is 6 × 10 4 The papain of U is continuously stirred for 1h to obtain enzymatic hydroly...

Embodiment 2

[0031] (1) After soaking and washing the kelp, add water 10 times the dry weight of the kelp and soak it naturally for 1.5 hours, squeeze the juice and pulverize it, collect the slag and juice together to obtain the kelp juice;

[0032] (2) Ultrasonic treatment of kelp juice, ultrasonic temperature 40°C, power 70W, time 30min;

[0033] (3) Add hydrochloric acid, citric acid and malic acid to the ultrasonically treated kelp juice to adjust the pH value to 4.5, adjust the temperature to 47°C, add 1.2% of the dry weight of kelp with an activity of 3×104U pectinase, Continue to stir for 1.5h; continue heating to raise the temperature to 57°C, add kelp dry weight 1.5% cellulase with an activity of 4×104U, and continue to stir for 1.5h; then add sodium hydroxide to the juice to adjust the pH to 6.5 , keep the temperature, add kelp dry weight 0.8% activity of papain with an activity of 6 × 104U, and continue stirring for 1-1.5h to obtain enzymatic hydrolysis juice;

[0034] (4) Perf...

Embodiment 3

[0039] (1) After soaking and washing the kelp, add water 12 times the dry weight of the kelp and soak it naturally for 2 hours, squeeze the juice and pulverize it, collect the slag and the juice together to obtain the kelp juice;

[0040] (2) Ultrasonic treatment of kelp juice, ultrasonic temperature 45°C, power 80W, time 35min;

[0041] (3) Add hydrochloric acid, citric acid and malic acid to the ultrasonically treated kelp juice to adjust the pH value to 5.0, adjust the temperature to 50°C, add 1.5% of the dry weight of kelp with an activity of 3×104U pectinase, Continue stirring for 2 hours; continue heating to raise the temperature to 60°C, add kelp dry weight 2% cellulase with an activity of 4×104U, and continue stirring for 2 hours; then add sodium hydroxide to the juice to adjust the pH to 7, keep temperature, add kelp dry weight 1.2% papain with an activity of 6×104U, and continue stirring for 1.5h to obtain enzymatic hydrolysis juice;

[0042] (4) Perform the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com