A kind of preparation method of double network sulfonated polyphenylene ether/acrylic resin composite material

A technology of sulfonated polyphenylene ether and composite material, which is applied in the field of polymer materials to achieve the effect of improving toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

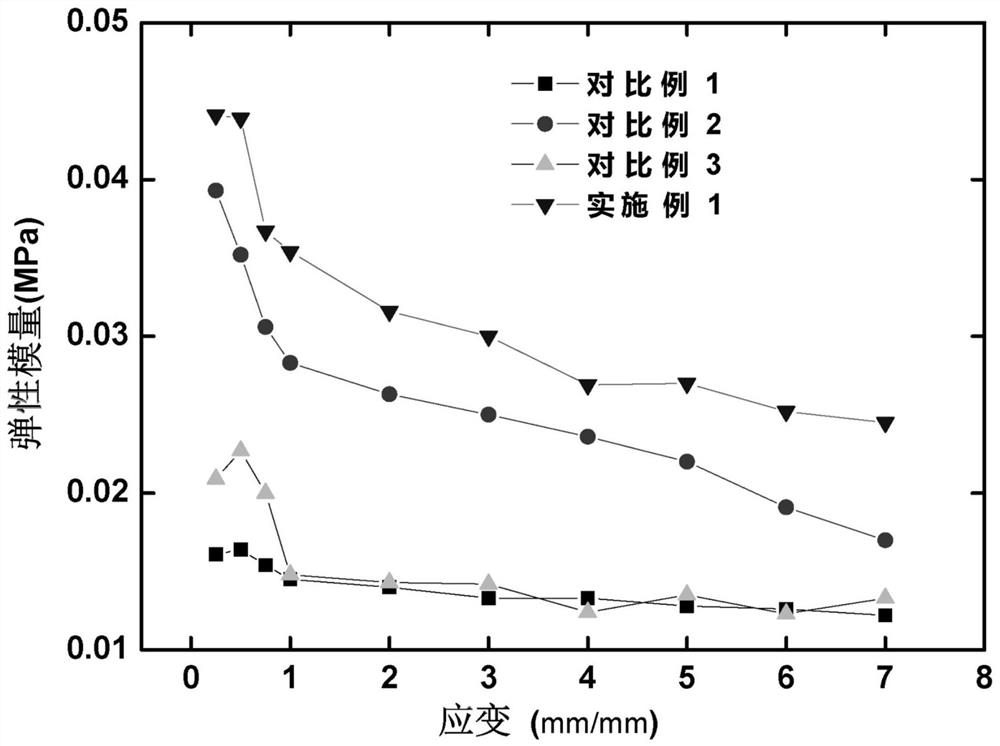

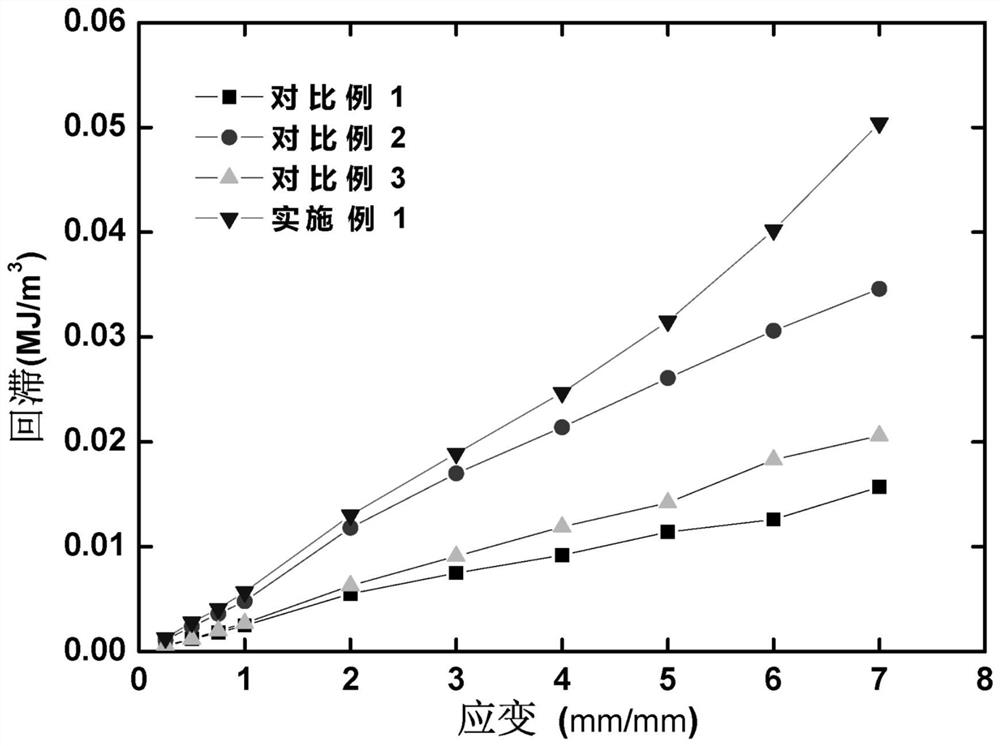

Embodiment 1

[0044] A preparation method of a double-network sulfonated polyphenylene ether / acrylate elastomer composite material, comprising the following steps:

[0045] 1) Preparation of sulfonated polyphenylene ether: add 95 g of chloroform and 5 g of PPO (polyphenylene ether) to a 250 mL three-necked flask, and uniformly stir at room temperature to form a homogeneous solution. Pipette an appropriate amount of chlorosulfonic acid (the molar ratio of polyphenylene ether and chlorosulfonic acid is 3:4), dilute it with chloroform into a solution of a certain concentration, cool it in an ice-water bath, and then transfer it to a constant pressure dropping funnel to start dropping , After the dropwise addition, the reaction was continued at room temperature for 1 h. The resulting product was washed with deionized water, and after lyophilization for 24 h, the sulfonated polyphenylene ether was prepared.

[0046] 2) dissolving the prepared sulfonated polyphenylene ether, ethyl acrylate, ethy...

Embodiment 2

[0050] A preparation method of a double-network sulfonated polyphenylene ether / acrylate elastomer composite material, comprising the following steps:

[0051] 1) Preparation of sulfonated polyphenylene ether: add 95 g of chloroform and 5 g of PPO to a 250 mL three-necked flask, and uniformly stir at room temperature to form a homogeneous solution. Pipette an appropriate amount of chlorosulfonic acid (the molar ratio of polyphenylene ether and chlorosulfonic acid is 3:4), dilute it with chloroform into a solution of a certain concentration, cool it in an ice-water bath, and then transfer it to a constant pressure dropping funnel to start dropping , After the dropwise addition, the reaction was continued at room temperature for 1 h. The resulting product was washed with deionized water, and after lyophilization for 24 h, the sulfonated polyphenylene ether was prepared.

[0052] 2) dissolving the prepared sulfonated polyphenylene ether, ethyl acrylate, ethylene glycol dimethacry...

Embodiment 3

[0056] A preparation method of a double-network sulfonated polyphenylene ether / acrylate elastomer composite material, comprising the following steps:

[0057] 1) Preparation of sulfonated polyphenylene ether: add 95 g of chloroform and 5 g of PPO to a 250 mL three-necked flask, and uniformly stir at room temperature to form a homogeneous solution. Pipette an appropriate amount of chlorosulfonic acid (the molar ratio of polyphenylene ether and chlorosulfonic acid is 3:4), dilute it with chloroform into a solution of a certain concentration, cool it in an ice-water bath, and then transfer it to a constant pressure dropping funnel to start dropping , After the dropwise addition, the reaction was continued at room temperature for 1 h. The resulting product was washed with deionized water, and after lyophilization for 24 h, the sulfonated polyphenylene ether was prepared.

[0058] 2) dissolving the prepared sulfonated polyphenylene ether, ethyl acrylate, ethylene glycol dimethacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com