Composition and method for detaching-free cleaning of inlet valve of direct-injection engine

A technology of cleaning composition and direct injection in the cylinder, which is applied in the field of cleaning and can solve the problems of bad influence of mechanical seal degree, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

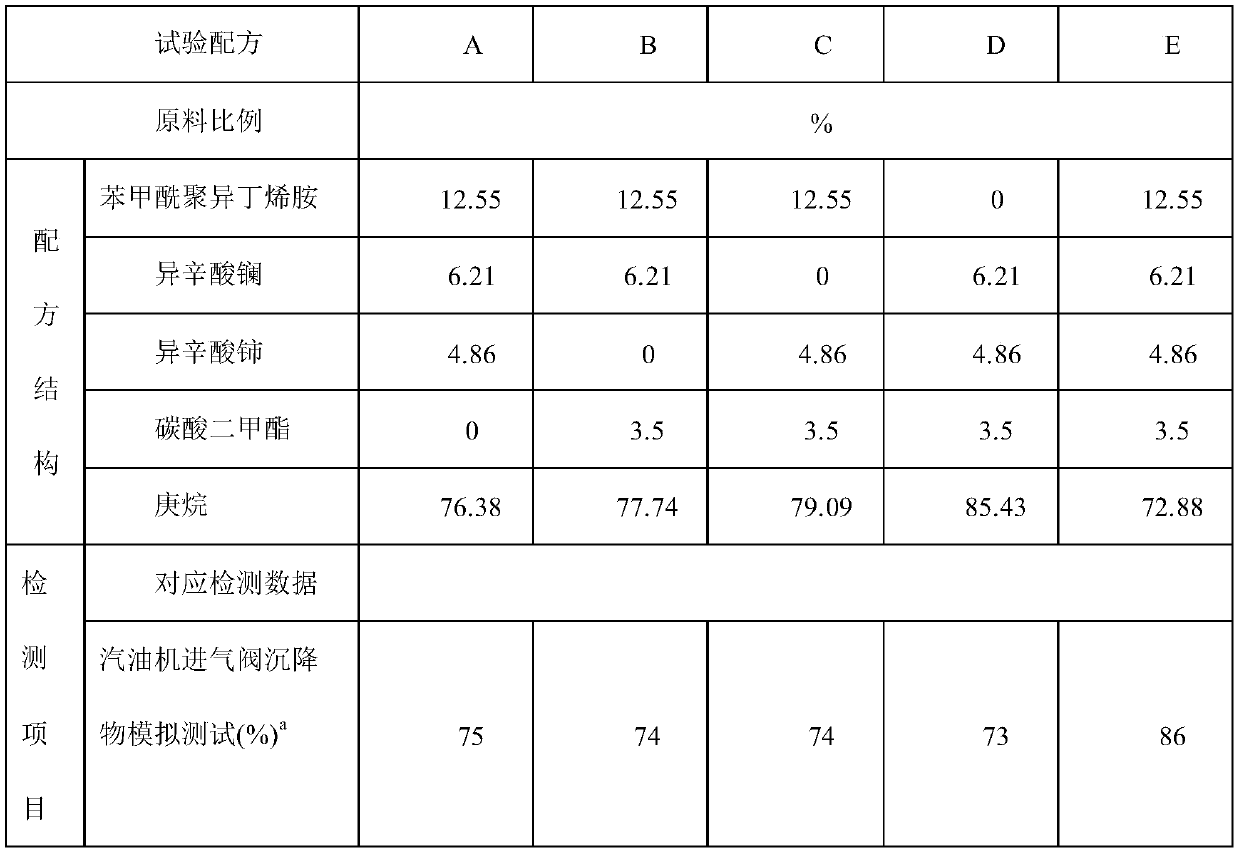

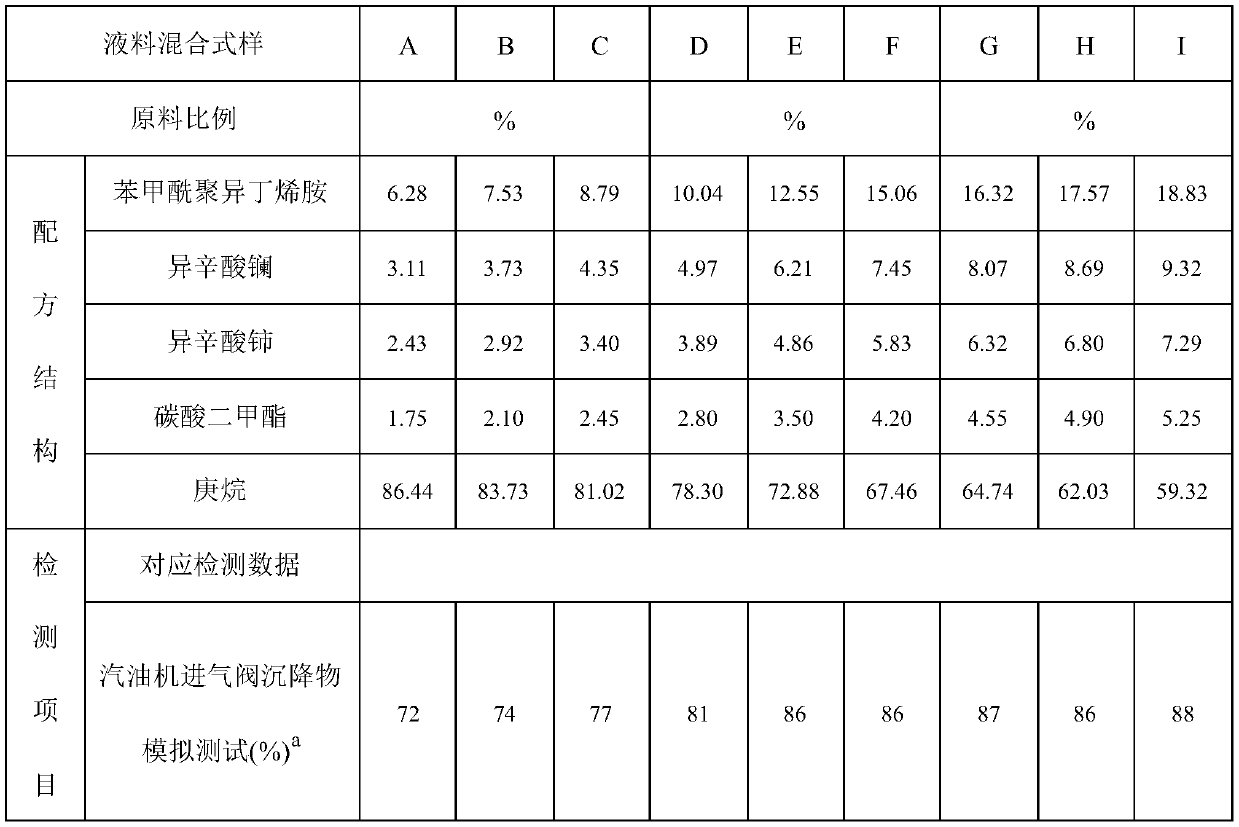

[0042] In order to facilitate those skilled in the art to understand the solution of the present invention, the solution of the present invention will be further described below in conjunction with specific examples. It should be understood that the embodiments of the present invention are explanations of the solution of the present invention, and are not intended to limit the protection scope of the present invention.

[0043] After the applicant conducted a laboratory analysis of the carbon deposits on the intake valve, we found that the carbon deposits on the intake valve contained more trace elements such as calcium, sulfur, phosphorus, zinc, and molybdenum. Most of these elements come from additives in engine oil, and gasoline contains less of them. Among them, the calcium element comes from the detergent, the sulfur element comes from the extreme pressure agent and anti-wear agent, the zinc element comes from the anti-wear agent and antioxidant, and the molybdenum element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com