Electrolytic polishing liquid, polishing device and polishing method

The technology of electrolytic polishing and polishing device is applied in the field of electrolytic polishing technology, which can solve the problems of operator safety threat, difficult treatment of waste water, eutrophication of water body, etc., and achieves the effect of good polishing effect and improved reaction and electrolysis speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The electrolytic polishing solution of this embodiment, the electrolytic polishing solution is calculated by weight, including 18-28wt% of sulfuric acid, 20-32wt% of citric acid, 5-15wt% of tartaric acid, 1-5wt% of surfactant, and the balance is deionized water. The concentration of sulfuric acid is 98%. Surfactants are anionic surfactants. The concentrations of citric acid, tartaric acid and surfactants were all analytically pure. The surfactant is one or more of sodium stearate, sodium dodecylbenzenesulfonate and sodium lauryl sulfate.

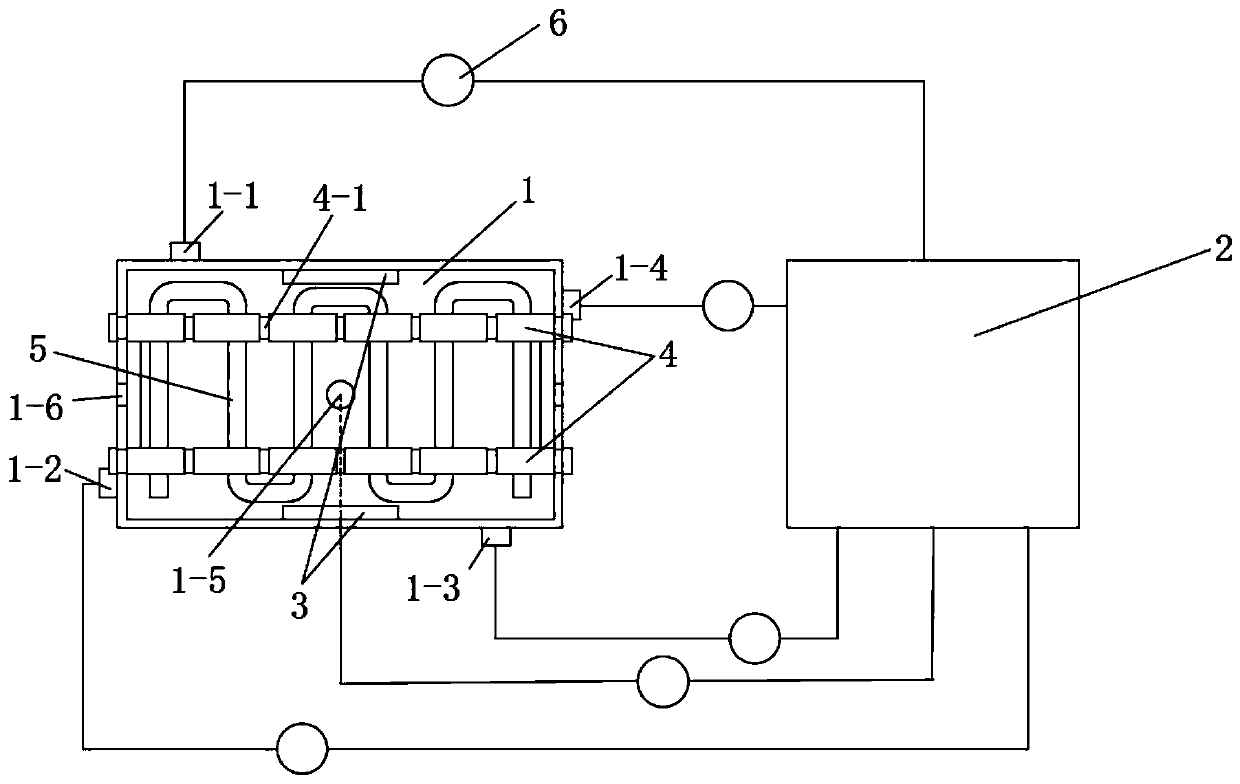

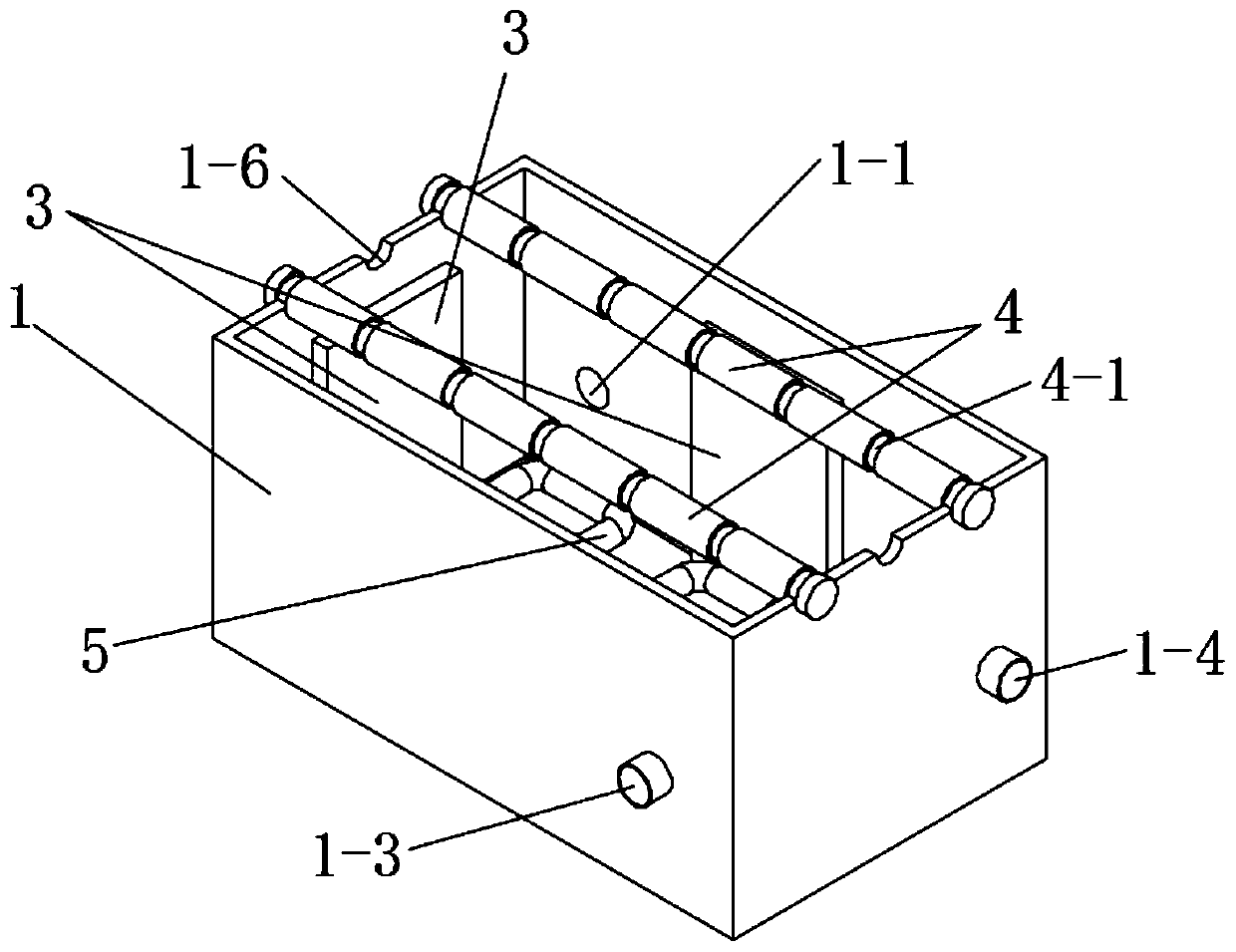

[0038] See figure 1 and figure 2 , a polishing device of this embodiment, including a reaction vessel 1, an ultrasonic generator, an electrolyte storage tank 2 and a power supply.

[0039] The electrolytic polishing solution mentioned above is filled in the electrolyte storage tank 2 . The reaction vessel 1 is provided with a conductive plate 3 . Mounting grooves 1-6 are evenly distributed along the front and rear directions o...

Embodiment 2

[0051] The workpiece processed in this embodiment is a quenched hollow drill with a complex inner surface structure, and the material grade is 420. The composition of the electrolyte in this embodiment: 28wt% of sulfuric acid, 30wt% of citric acid, 8wt% of tartaric acid, 3wt% of sodium dodecylbenzenesulfonate, 1wt% of sodium dodecylsulfate, and 30wt% of water. The electrolyte temperature is 55°C, the voltage is 7 volts, the current density is 50A / dm2, and the electrolysis time is 30S. The ultrasonic power is 1.2KW and the frequency is 25KHZ.

[0052] Electrolysis effect: small holes, the oxide skin on the inner surface of the cutting edge is removed, and the roughness of the inner surface is significantly reduced.

Embodiment 3

[0054] The workpiece processed in this embodiment is a quenched guide frame with threaded holes, and the material grade is 17-4. Electrolyte composition: sulfuric acid 25wt%, citric acid 30wt%, tartaric acid 10wt%, sodium stearate 3wt%, sodium lauryl sulfate 2wt%, water 30wt%. The electrolyte temperature is 50°C, the voltage is 8 volts, the current density is 30A / dm2, and the electrolysis time is 100S. Ultrasonic power is 1.2KW, frequency is 28KHZ.

[0055] Electrolysis effect: the burr in the threaded hole is removed, and the oxide skin is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com