High-consistency photoacoustic excitation and detecting integrated fiber probe, manufacturing method and testing method thereof

A technology of optical fiber probes and manufacturing methods, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of uncontrollable thickness of photothermal absorption materials, unfavorable miniaturization and integrated measurement, and affecting the consistency of probe performance, etc. problems, to achieve the effects of improving excitation efficiency, improving photothermal heat absorption capacity, and avoiding direction calibration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

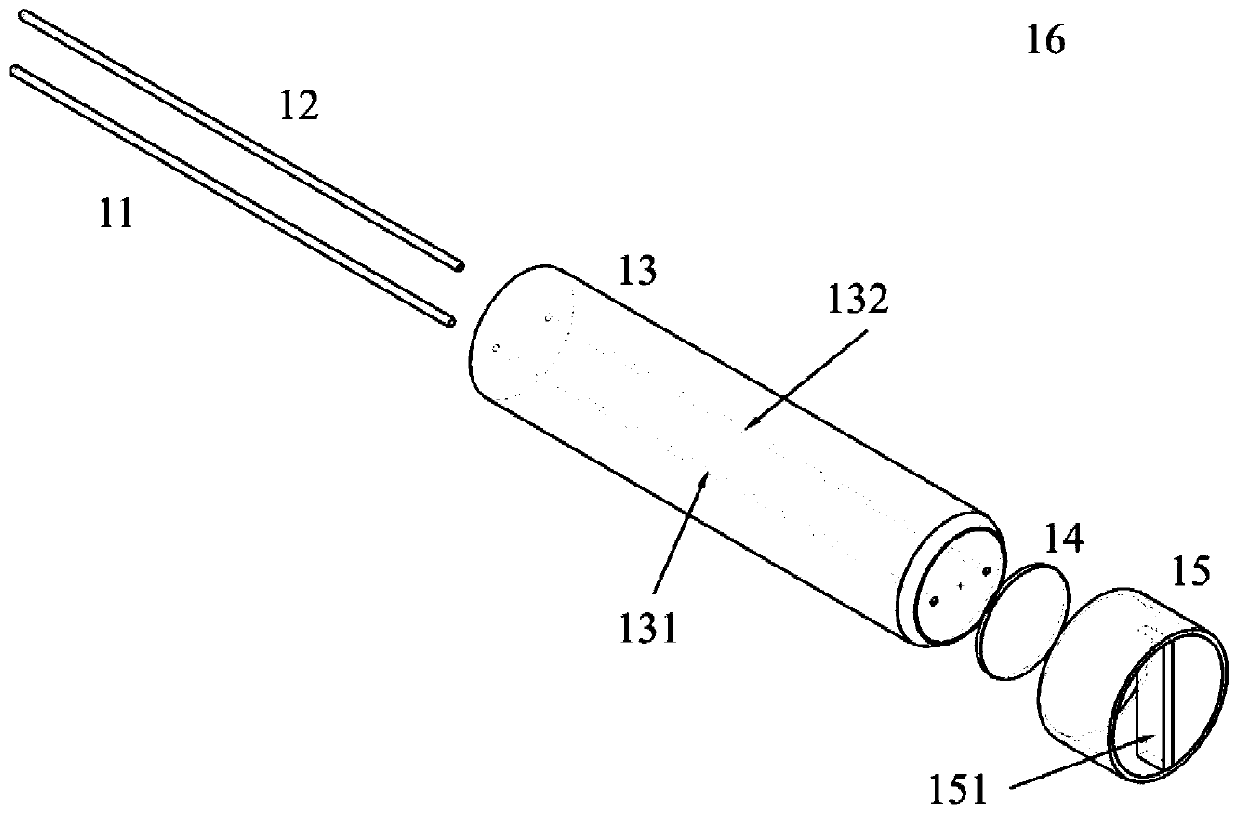

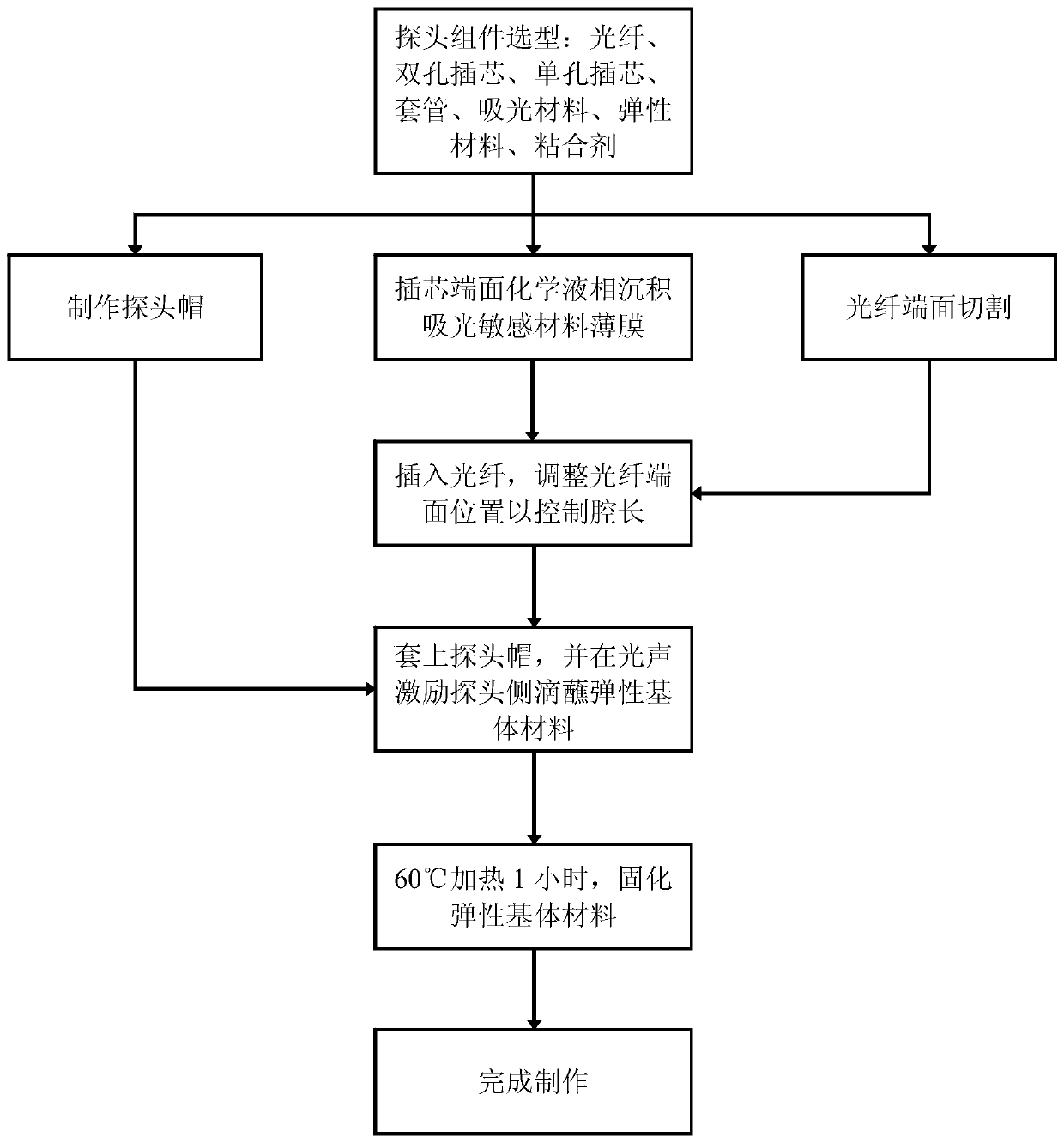

[0029] figure 1 It is a structural schematic diagram of the photoacoustic excitation and detection integrated controllable probe of the present invention. The probe is mainly composed of a double-clad optical fiber 11 , a single-mode optical fiber 12 , a double-hole ceramic ferrule 13 , a heat-absorbing material film 14 and a probe cap 15 . The double-clad fiber 11 is used to transmit pulsed laser to realize photoacoustic excitation. The single-mode optical fiber 12 is used to transmit tunable laser light to realize optical fiber F-P detection of ultrasonic signals. The double-clad optical fiber 11 and the single-mode optical fiber 12 are inserted into the hole 131 and the hole 132, respectively. The heat-absorbing material is molybdenum disulfide film as an example, which is transferred and prepared on the end face of the double-hole ceram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com