Induction motor rotor broken bar fault diagnosis method based on wavelet packet support vector machine

A support vector machine and rotor broken bar technology, applied in the direction of motor generator testing, etc., can solve problems such as small component amplitude, difficulty in identifying faults, small slip rate, etc., achieve reliable and practical significance, realize predictive diagnosis, and avoid signal The effect of sampling too long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

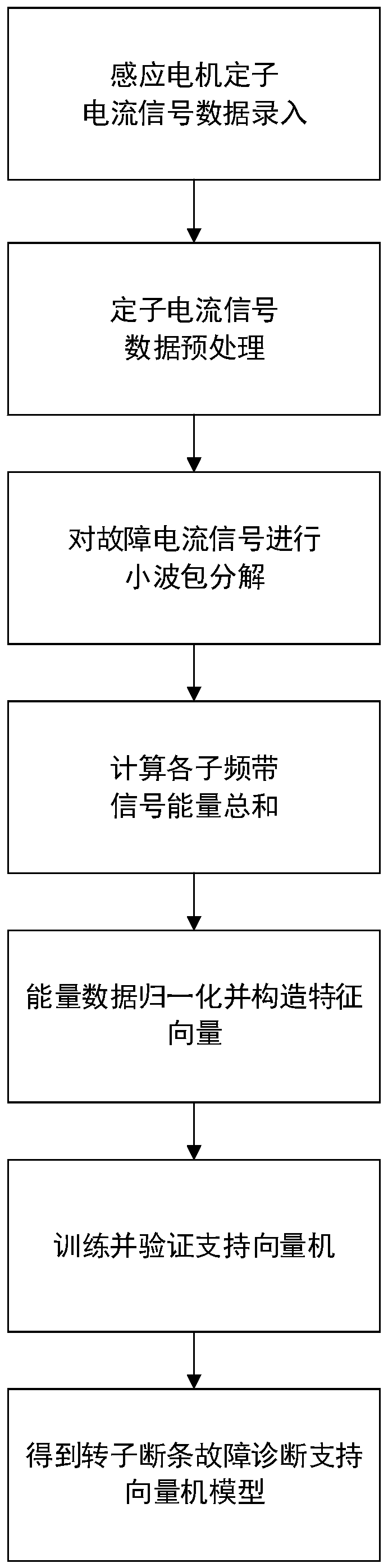

[0027] see figure 1 , the present invention is based on the wavelet packet support vector machine induction motor rotor broken bar fault diagnosis method, the steps are as follows:

[0028] The first step: preprocessing of the fault current signal, denoising the original fault current of the stator winding. Preprocess the stator current data of the detected broken rotor bar fault of the induction motor, and filter out the power frequency stator current component and high frequency noise component in the stator current fault signal through SVD filtering technology based on singular value decomposition, and only retain the fault component , and store the data.

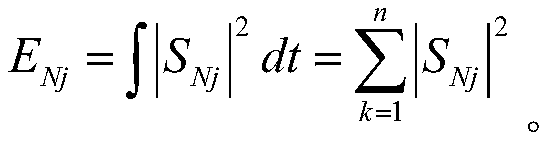

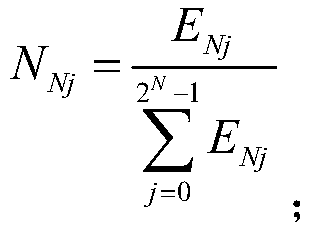

[0029] In the second step, the fifth-order wavelet packet decomposition is performed on the fault current signal to obtain the fault current signal components of each sub-band. The five-layer wavelet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com