Indoor circular optical cable and manufacturing method thereof

A kind of optical cable and circular technology, which is applied in the field of indoor circular optical cable and its production, can solve the problems of complete damage of optical cable, difficulty in meeting the specific requirements of fire protection, interruption of line communication, etc., and achieve small diameter, good insulation performance, and good durability The effect of combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

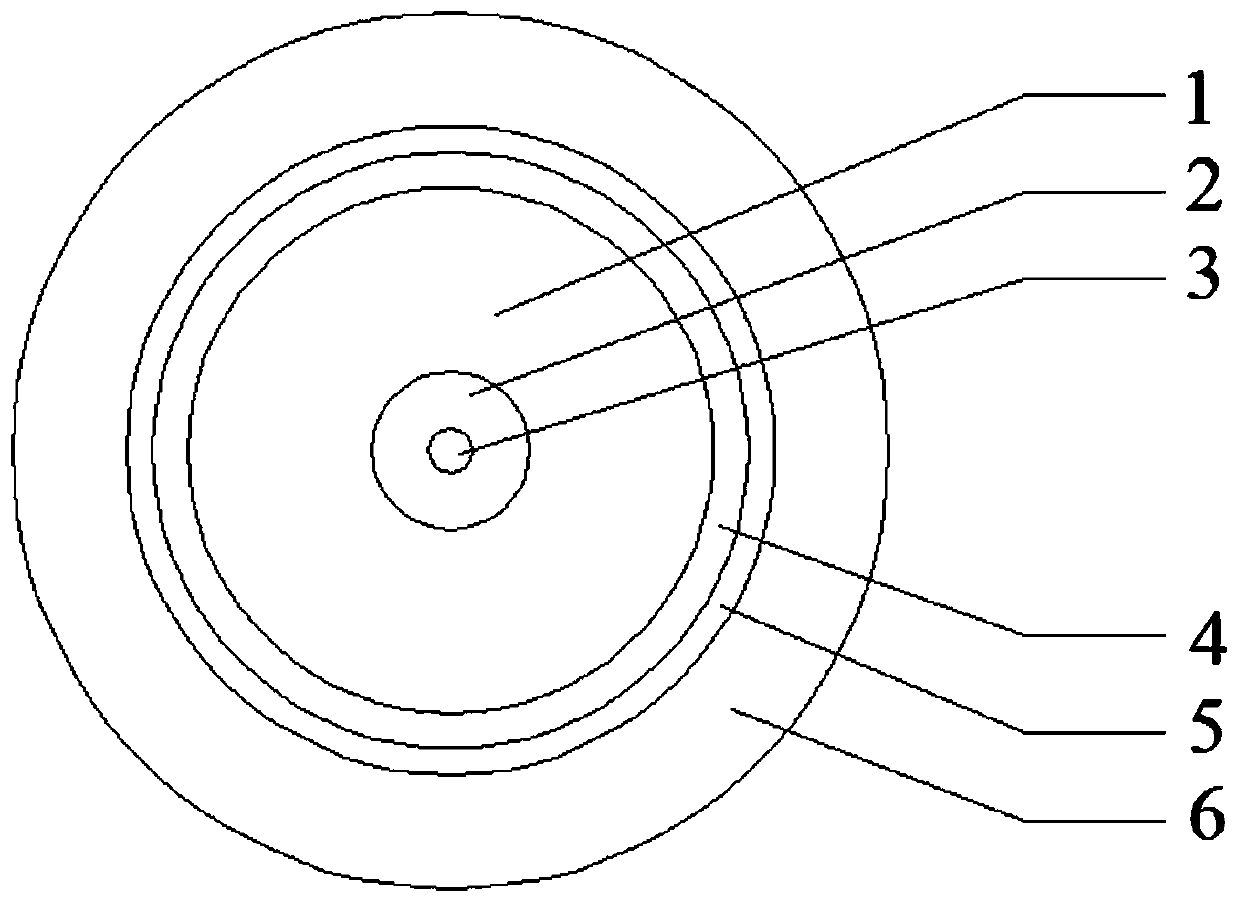

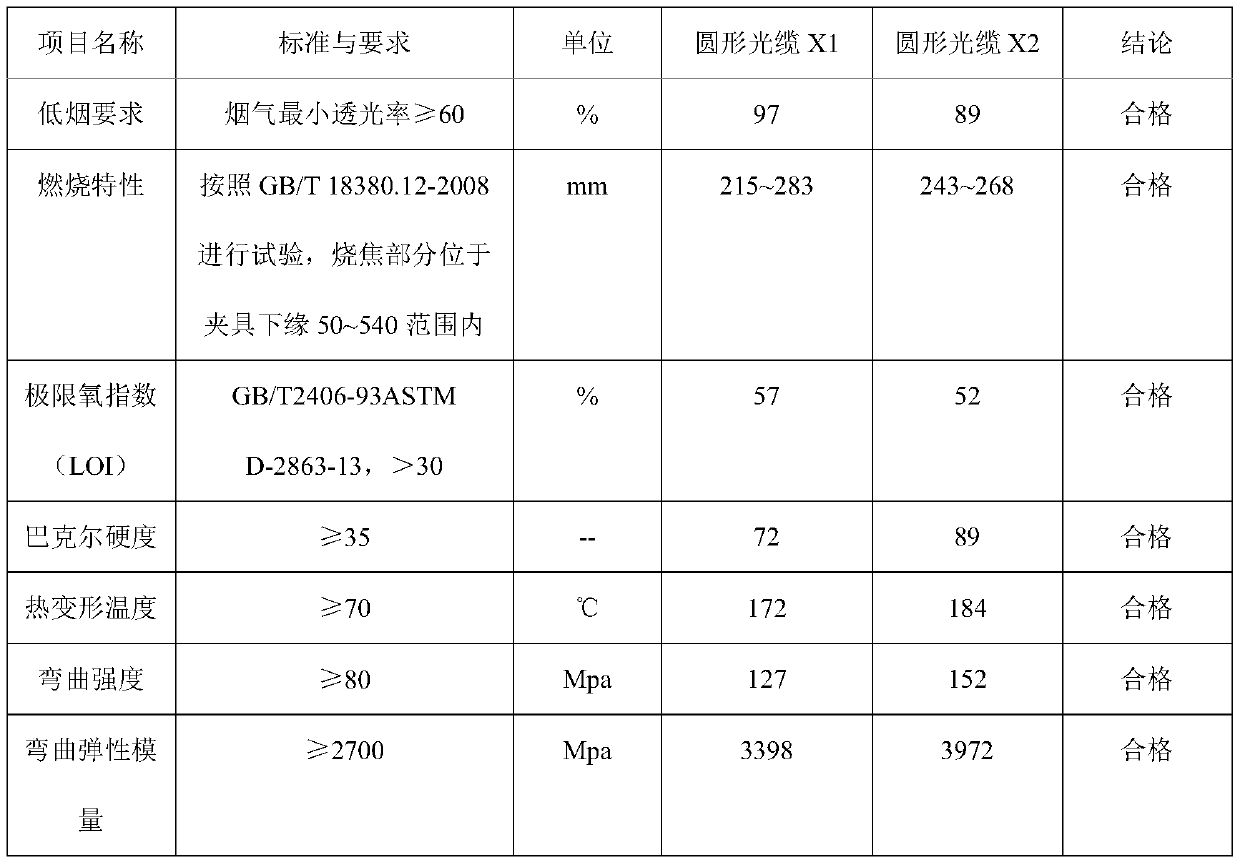

[0030] Embodiment 1 Indoor circular optical cable X1

[0031] The inner center of the indoor round optical cable X1 is a basic color fiber without coating. LSZH optical fiber tight sleeve with a thickness of 0.2mm is wrapped around the optical fiber. The optical fiber tight sleeve is wrapped with 8 pieces of 1610dtex type aramid yarn. The outside of the aramid yarn is wrapped with a ceramicized fireproof and refractory composite tape with a thickness of 0.05mm and a width of 12mm at an overlapping rate of 15% to form an isolation layer. The outside of the isolation layer is wrapped with a single-sided phlogopite mica tape with a thickness of 0.05mm and a width of 20mm at an overlapping rate of 15% to form a fireproof layer. The outside of the fireproof layer is a low-smoke, halogen-free, flame-retardant polyolefin sheath with a thickness of 0.5mm extruded.

[0032] The outer diameter of the tight sleeve layer of the indoor circular optical cable X1 is 0.6mm, the outer diame...

Embodiment 2

[0035] Embodiment 2 Indoor circular optical cable X2

[0036] The inner center of the indoor round optical cable X3 is a colorless optical fiber without coating. Consists of 0.35mm thick LSZH fiber tight sleeve on the outside of the fiber. The outer part of the optical fiber tight sleeve consists of 12 pieces of 1500dtex type aramid yarn. The outer part of the aramid yarn is wrapped with a ceramicized fireproof and refractory composite tape with a thickness of 0.3mm and a width of 12mm with an overlap rate of 35% to form an isolation layer. The outside of the isolation layer is wrapped with a single-sided phlogopite mica tape with a thickness of 0.1mm and a width of 14mm with an overlapping rate of 18% to form a fireproof layer. The outside of the fireproof layer is a low-smoke, halogen-free, flame-retardant polyolefin sheath with a thickness of 0.5mm extruded.

[0037] The outer diameter of the tight sleeve layer of the indoor circular optical cable X1 is 0.4mm, the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com