Efficient joint production method of propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate

A technology for propylene glycol methyl ether acetate and propylene glycol methyl ether, which is applied in the field of high-efficiency co-production of propylene glycol methyl ether and propylene glycol methyl ether acetate, and can solve the problems of unsatisfactory catalytic effect and process, high separation energy consumption, and high cost of wastewater treatment. , to achieve the effect of improving comprehensive utilization rate, good application performance and low energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

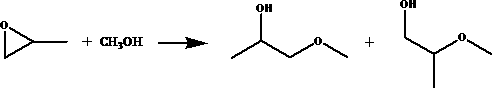

[0027] (1), Preparation of propylene glycol methyl ether crude ester: After mixing the raw materials propylene oxide and methanol evenly, under the catalytic condition of a medium-strong alkali solid catalyst, the propylene glycol methyl ether crude ester is generated successively through a constant temperature reactor and an adiabatic reactor. In the adiabatic reactor, the boring of flowing methyl acetate as the heat conduction oil pipe;

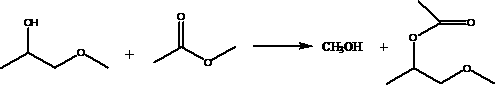

[0028] (2) Preparation of propylene glycol methyl ether acetate: Part of the propylene glycol methyl ether crude ester generated in step (1) is transferred to the esterification tower and mixed with the preheated methyl acetate in the heat conduction oil pipe, and transesterified under the acidic cationic resin The reaction produces propylene glycol methyl ether acetate.

[0029] Further, the molar ratio of propylene oxide to methanol in step (1) is 1:3-1:5; the reaction pressure of the adiabatic reactor is 0.8-2 MPa.

[0030] Further, in ...

Embodiment 1

[0034] The invention discloses a method for high-efficiency co-production of propylene glycol methyl ether and propylene glycol methyl ether acetate, using propylene oxide, methanol, and methyl acetate as raw materials, comprising the following steps:

[0035] (1), Preparation of propylene glycol methyl ether crude ester: After mixing the raw materials propylene oxide and methanol evenly, under the catalytic condition of a medium-strong alkali solid catalyst, the propylene glycol methyl ether crude ester is generated successively through a constant temperature reactor and an adiabatic reactor. In an adiabatic reactor, the flowing methyl acetate is used as the bore of the heat conducting oil tube. In this step, the molar ratio of propylene oxide to methanol is 1:5; the reaction pressure of the adiabatic reactor is 1.4Mpa; the strong base solid catalyst is a basic resin solid base of tertiary amine or tertiary phosphine group.

[0036] (2) Preparation of propylene glycol methyl ...

Embodiment 2

[0038] The invention discloses a method for high-efficiency co-production of propylene glycol methyl ether and propylene glycol methyl ether acetate, using propylene oxide, methanol, and methyl acetate as raw materials, comprising the following steps:

[0039] (1), Preparation of propylene glycol methyl ether crude ester: After mixing the raw materials propylene oxide and methanol evenly, under the catalytic condition of a medium-strong alkali solid catalyst, the propylene glycol methyl ether crude ester is generated successively through a constant temperature reactor and an adiabatic reactor. In an adiabatic reactor, the flowing methyl acetate is used as the bore of the heat conducting oil tube. In this step, the molar ratio of propylene oxide to methanol is 1:4; the reaction pressure of the adiabatic reactor is 0.8Mpa; the strong base solid catalyst is a molecular sieve loaded with CaO and MgO.

[0040] (2) Preparation of propylene glycol methyl ether acetate: Part of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com