Application of UV curing coat in anti-dazzling thin membrane for automobile rear view mirror or side view mirror

A technology for automotive rearview mirrors and curing coatings, applied in polyether coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as safety accidents, film surface fogging, fogging, etc., to prevent fogging and improve driving safety. The effect of good anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-3

[0028] a. Add initiator in the container according to the ratio in Table 1, then add solvent or reactive diluent, and stir;

[0029] b. After stirring evenly, add polyurethane acrylate and stir;

[0030] c. After stirring evenly, add the surface additive while stirring slowly, and stir until the system is uniform and transparent, and then the UV curable coating is obtained.

[0031] Application of cured coatings in anti-glare films for automotive rear-view mirrors or side-view mirrors:

[0032] Coat the coating prepared above on a transparent plastic substrate by means of spraying, and cure it into a coating film by ultraviolet rays. On the glass mirror surface, the gloss and hardness of the coating film were tested. The specific testing standards and results are shown in Table 3.

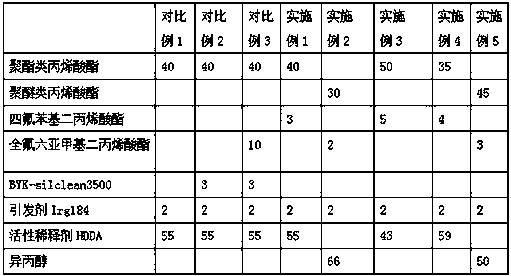

[0033] Table 1 The specific proportioning (parts by weight) of each component in each embodiment and comparative examples

[0034]

[0035] The performance test data of each embodiment of tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com