High-fastness suit fabric dyeing process

A high color fastness and fabric technology, applied in the field of dyeing technology, can solve problems such as poor color fastness, achieve the effect of improving dyeing rate and color fastness, and excellent hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

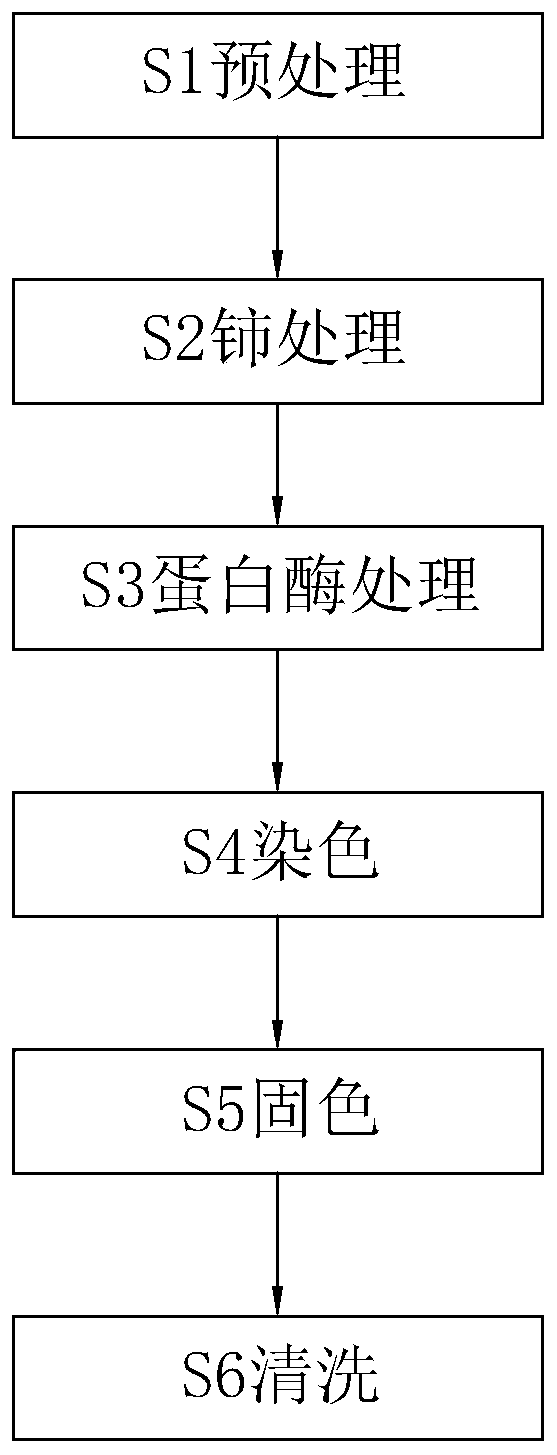

[0039] A kind of high color fastness dyeing process of suit fabric, suit fabric is pure wool fabric, such as figure 1 shown, including the following steps:

[0040] S1 pretreatment: first heat the pretreatment solution to 40°C, then immerse the fabric in the pretreatment solution, the bath ratio is 1:20, then raise the temperature to 80°C at a rate of 2°C / min, keep it warm for 30 minutes, cool to room temperature and take it out , and then washed with hot water at 50°C for 10 minutes, and finally dried. The pretreatment solution includes 2g / L hydrogen peroxide, 3g / L sodium hydroxide, 1g / l penetrant, and the rest is water;

[0041] S2 cerium treatment: immerse the fabric in the cerium treatment solution for 50 minutes, the bath ratio is 1:25, the temperature is 35°C, the cerium treatment solution includes 8g / L cerium nitrate, 20g / LBTCA, and the rest is water, after the treatment is completed, wash and dry ;

[0042] S3 protease treatment: immerse the fabric in the protease so...

Embodiment 2

[0052] A kind of high color fastness dyeing process of suit fabric, suit fabric is pure wool fabric, such as figure 1 shown, including the following steps:

[0053] S1 pretreatment: first heat the pretreatment solution to 50°C, then immerse the fabric in the pretreatment solution, the bath ratio is 1:20, then raise the temperature to 90°C at a rate of 3°C / min, keep it warm for 40min, cool to room temperature and take it out , and then washed with hot water at 60°C for 15 minutes, and finally dried. The pretreatment solution includes 3g / L hydrogen peroxide, 5g / L sodium hydroxide, 2g / l penetrant, and the rest is water;

[0054] S2 cerium treatment: immerse the fabric in the cerium treatment solution for 60 minutes, the bath ratio is 1:25, the temperature is 45°C, the cerium treatment solution includes 10g / L cerium nitrate, 25g / LBTCA, and the rest is water. After the treatment is completed, wash and dry ;

[0055] S3 protease treatment: immerse the fabric in the protease soluti...

Embodiment 3

[0065] A kind of high color fastness dyeing process of suit fabric, suit fabric is pure wool fabric, such as figure 1 shown, including the following steps:

[0066] S1 pretreatment: first heat the pretreatment solution to 45°C, then immerse the fabric in the pretreatment solution, the bath ratio is 1:20, then raise the temperature to 85°C at a rate of 2.5°C / min, keep it warm for 35min, cool to room temperature and take it out , and then washed with hot water at 55°C for 12 minutes, and finally dried. The pretreatment solution includes 2.5g / L hydrogen peroxide, 4g / L sodium hydroxide, 1.5g / l penetrant, and the rest is water;

[0067] S2 cerium treatment: immerse the fabric in the cerium treatment solution for 55 minutes, the bath ratio is 1:25, the temperature is 40°C, the cerium treatment solution includes 9g / L cerium nitrate, 22g / LBTCA, and the rest is water, after the treatment is completed, wash and dry ;

[0068] S3 protease treatment: immerse the fabric in the protease s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com