Waterproof low-smoke halogen-free flame retardant paper and preparing method thereof

A flame retardant paper and paper technology, applied in the field of packaging materials, can solve the problems of releasing toxic and harmful gases, affecting personal safety, and many laminating processes, and achieving the effects of improving paper strength, wide process window and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

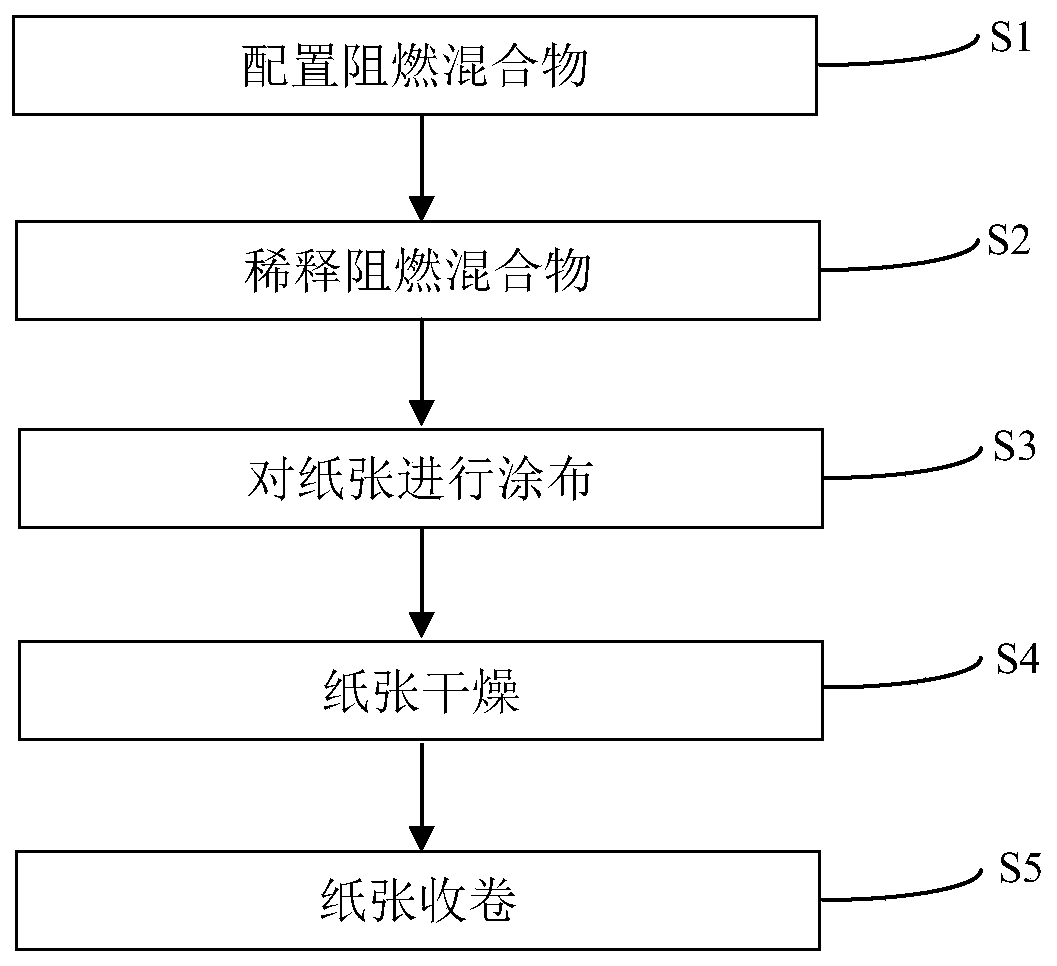

[0045] as attached figure 1 Shown, a kind of preparation method with waterproof low-smoke halogen-free flame-retardant paper comprises the following steps:

[0046] S1, preparing flame retardant mixture, including the following components in weight percentage: poly(3-hydroxyphenyl) phosphate 75%, diphenylmethane diisocyanate (MDI) 20%, catalyst 1%, smoke suppressant 4%, A flame-retardant mixture is obtained, wherein the catalyst is dibutyltin di(dodecylsulfur), and the smoke suppressant is a hydrotalcite smoke suppressant;

[0047] Wherein, preparing flame retardant mixture comprises the following steps:

[0048] S11. First, poly(3-hydroxyphenyl) phosphate is added into the stirring tank according to the proportion, the stirring speed is 100r / min, the stirring time is 20min, and the mixing and dispersion are uniform;

[0049] S12, after step S11, add hydrotalcite smoke suppressant, stirring speed 100r / min, stirring time 10min;

[0050] S13, after step S12, add isocyanate, s...

Embodiment 2

[0058] as attached figure 1 Shown, a kind of preparation method with waterproof low-smoke halogen-free flame-retardant paper comprises the following steps:

[0059] S1, prepare flame-retardant mixture, comprise the component of following percentage by weight: poly(3-hydroxyphenyl) phosphate 95%, diphenylmethane diisocyanate 3%, catalyst 0.1%, smoke suppressant 1.9%, make flame retardant Combustible mixture, wherein the catalyst is dibutyltin dilaurate, and the smoke suppressant is hydrotalcite smoke suppressant;

[0060] Wherein, preparing flame retardant mixture comprises the following steps:

[0061] S11. First, poly(3-hydroxyphenyl) phosphate is added into the stirring tank according to the proportion, the stirring speed is 500r / min, the stirring time is 5min, and the mixture is uniformly dispersed;

[0062] S12, after step S11, add hydrotalcite smoke suppressant, stirring speed 500r / min, stirring time 5min;

[0063] S13, after step S12, add isocyanate, stirring speed 50...

Embodiment 3

[0071] as attached figure 1 Shown, a kind of preparation method with waterproof low-smoke halogen-free flame-retardant paper comprises the following steps:

[0072] S1, preparing flame retardant mixture, comprising the following components in weight percentage: poly(3-hydroxyphenyl) phosphate 80%, diphenylmethane diisocyanate 15%, catalyst 0.5%, hydrotalcite smoke suppressant 4.5%, made Obtain a flame-retardant mixture, wherein the catalyst is dibutyltin dilaurate, and the smoke suppressant is a hydrotalcite smoke suppressant;

[0073] Wherein, preparing flame retardant mixture comprises the following steps:

[0074] S11. First, poly(3-hydroxyphenyl) phosphate is added into the stirring tank according to the proportion, the stirring speed is 200r / min, the stirring time is 15min, and the mixing and dispersion are uniform;

[0075] S12, after step S11, add hydrotalcite smoke suppressant, stirring speed 200r / min, stirring time 8min;

[0076] S13, after step S12, add isocyanate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com