Anti-collision device and workpiece table system

A technology of an anti-collision device and a workpiece table, applied in the field of lithography, can solve the problems of difficult simulation simulation, complicated installation and debugging, large self-weight, etc., and achieve the effects of simple structure layout, improved anti-collision performance, and saving a lot of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

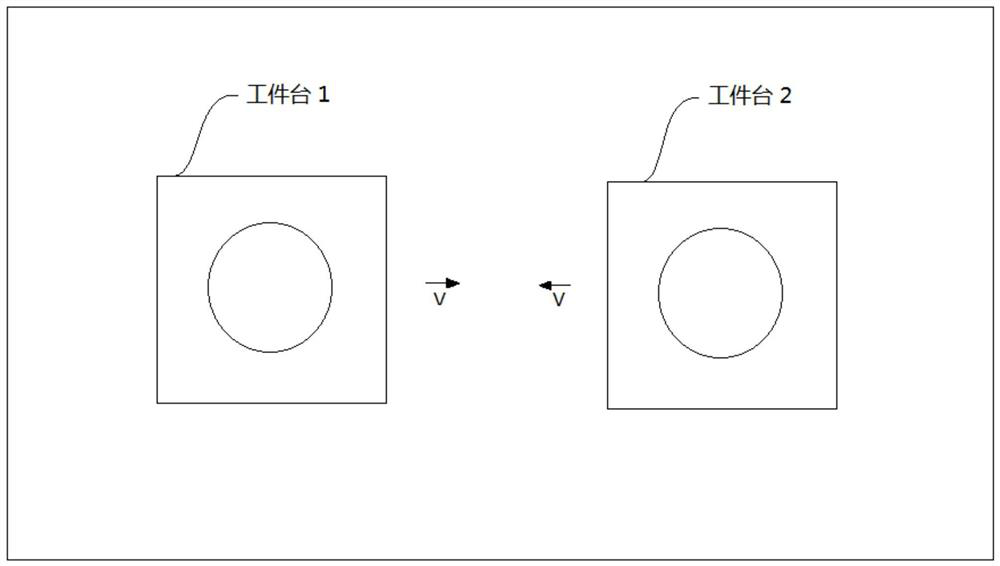

[0037] Such as figure 1 Shown is a schematic diagram of the main impact of two workpiece tables, driven by their respective drive units, the two workpiece tables move towards each other at a speed V on the working area to collide. Wherein, each workpiece table also includes a frame, the workpiece table is fixed on the frame, and the driving unit of the workpiece table drives the frame to drive the workpiece table to move, and figure 1 The drive unit and frame of the workpiece table are not shown in the figure.

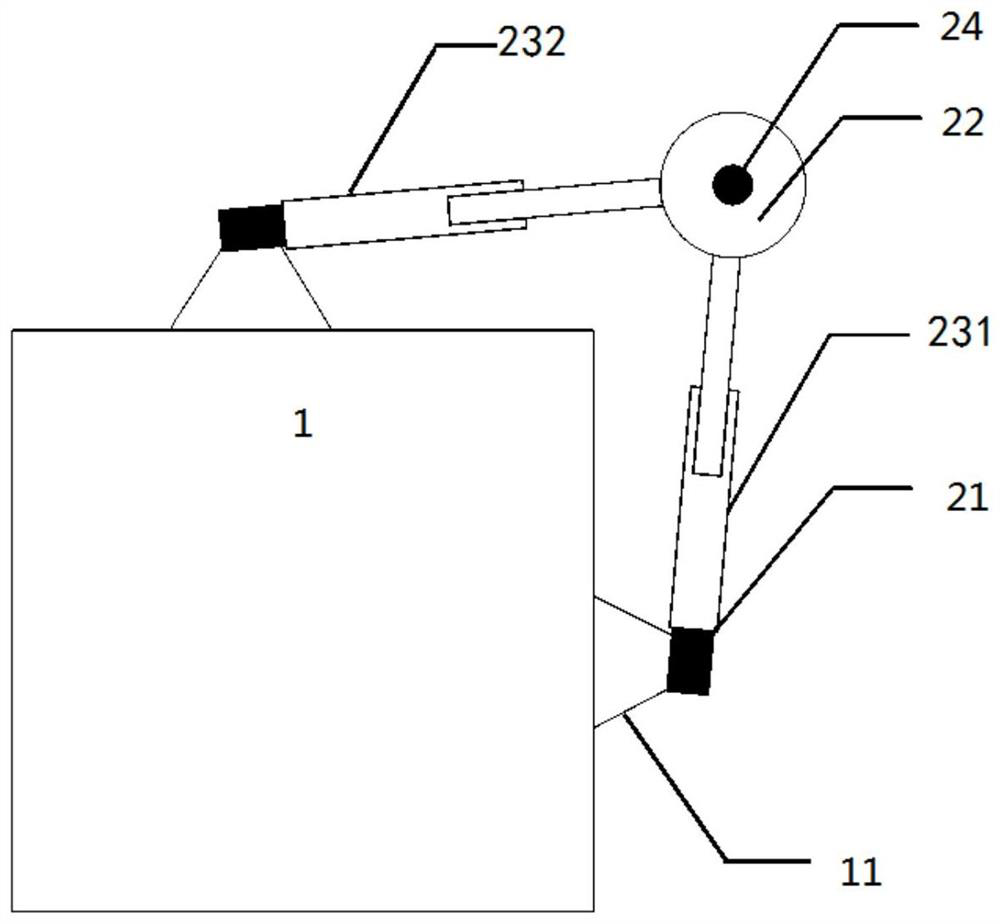

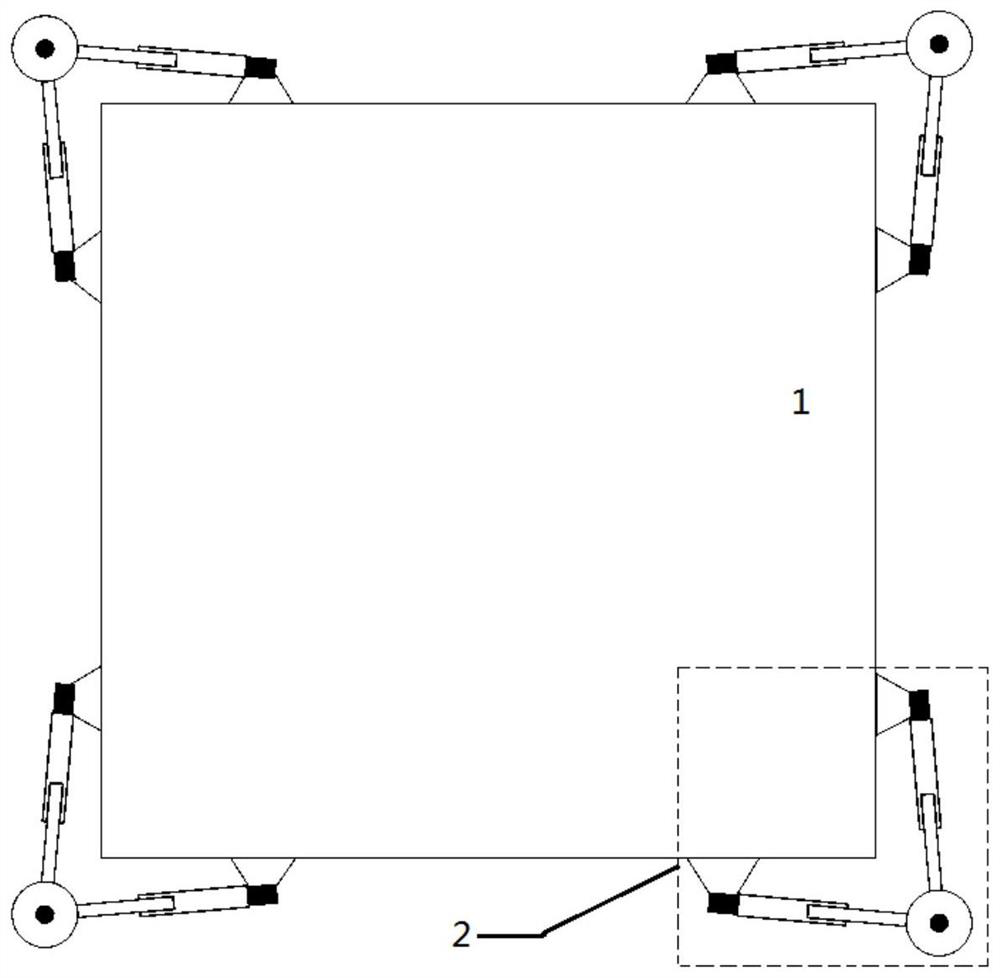

[0038] In order to protect the two workpiece tables, an anti-collision mechanism 2 is installed on the frame 1 of each workpiece table, such as figure 2 As shown, the anti-collision mechanism 2 is connected to the frame 1 of the workpiece table through two first hinges 21, and is used to protect the internal workpiece table components of the frame 1 from damage caused by the collision of the frame 1 in the movement plane. The frame 1 and the anti-collision mechanism...

Embodiment 2

[0054] In addition, considering that the collision between workpiece table systems may occur in addition to the collision situation in the first embodiment, such as Figure 6 In the collision situation shown, in order to make the anti-collision device cope with this special situation (if it is tested, it does exist), the structure of the anti-collision device in Embodiment 1 is improved, and a rectangular ring 25 is added. At the same time, the two buffer structures 231 and 232 can also be replaced with bi-directional buffers of other brands (not ACE brand).

[0055] Specifically, see Figure 7 , the anti-collision mechanism 2 includes a roller 22 and two buffer structures: a first buffer structure 231 or a second buffer structure 232, the roller 22 is connected to one end of the two buffer structures 231, 232 respectively through a second hinge 24, and the two buffer structures The other ends of the structures 231 and 232 are respectively connected with a first hinge 21 .

...

Embodiment 3

[0062] In addition, considering that the structure of the anti-collision mechanism 2 in the first and second embodiments may have vertical (Z direction) stability problems, the anti-collision mechanism 2 is further improved by adding a vertical stability module.

[0063] Specifically, see Figure 8 The anti-collision mechanism 2 includes a roller 22 and two buffer structures: a first buffer structure 231 or a second buffer structure 232, the roller 22 is connected with one end of the buffer structures 231, 232 through the second hinge 24, and the other end of the buffer structures 231, 232 One end is connected with a first hinge 21 respectively. The anti-collision mechanism 2 also includes a rectangular ring 25 fixed in the rollers 22 through grooves provided in the four rollers 22 .

[0064] In particular, the anti-collision mechanism 2 further includes a vertical stabilization module 26 disposed between the frame 1 and the buffer structures 231 , 232 . Wherein, the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com